Single-phase electronically commutated motor

An electronic commutation, single-phase technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of lower motor efficiency, inequality, large average air gap, etc., and achieve the effect of avoiding lamination offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

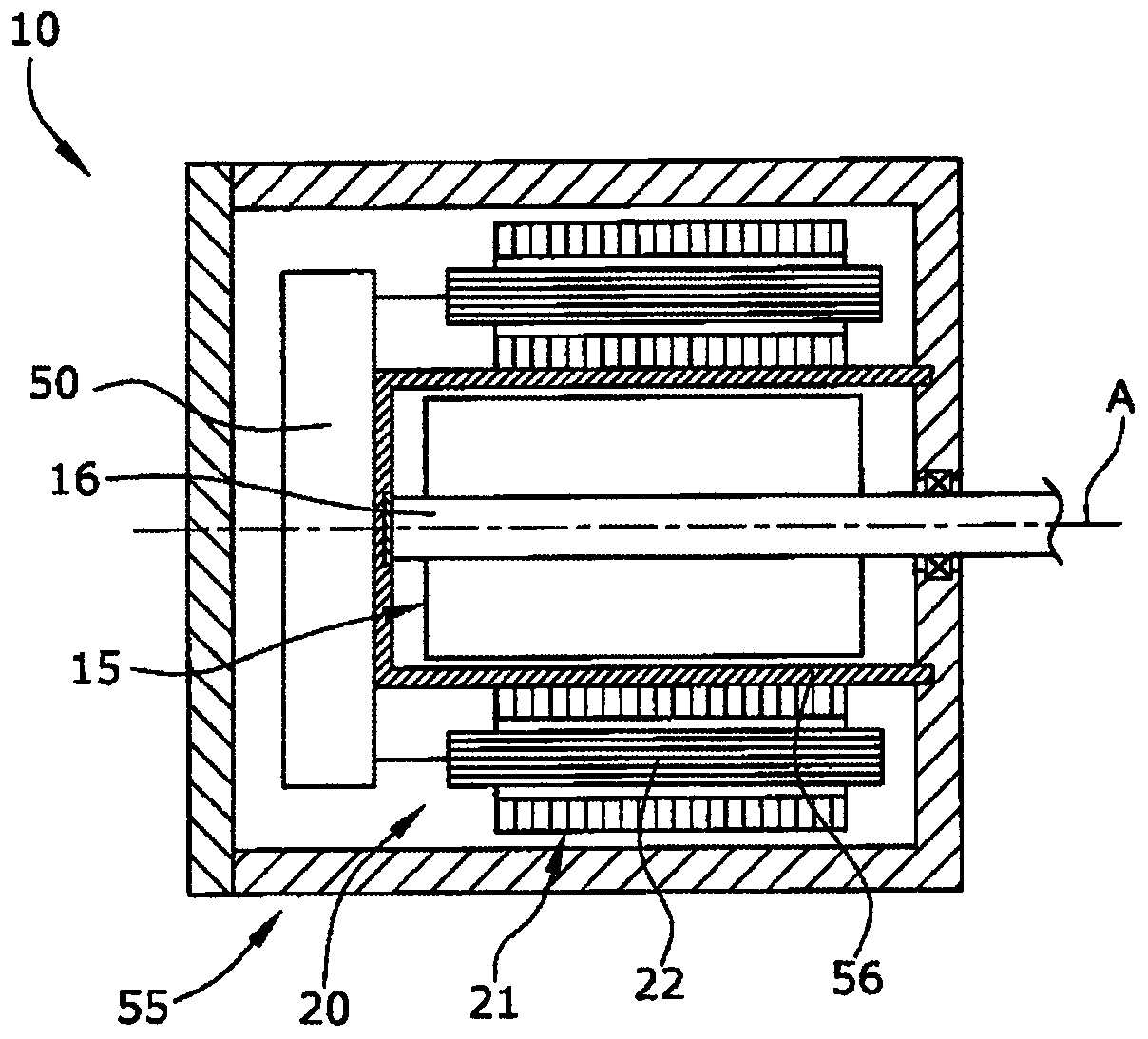

[0020] figure 1 A single phase electronically commutated electric machine 10 is shown provided with a permanent magnet electric machine rotor 15 rotatably attached to a motor shaft 16 . The motor 10 is also provided with a motor stator 20 including a laminated stator body 21 and stator coils 22 . The electric machine 10 includes a motor control unit 50 electrically connected to the stator coils 22 to energize the stator coils 22 . The motor 10 also includes a motor housing 55 and a motor can 56 .

[0021] The electric machine 10 is provided as a so-called canned electric machine, in which the electric machine can 56 fluidly separates the electric machine rotor 15 from the electric machine stator 20 . The motor rotor 15 is arranged inside the motor can 56 , and the surrounding motor stator 20 is arranged outside the motor can 56 . The motor rotor 15 is rotatable about the axis of rotation A and is non-rotatably attached to the motor shaft 16 .

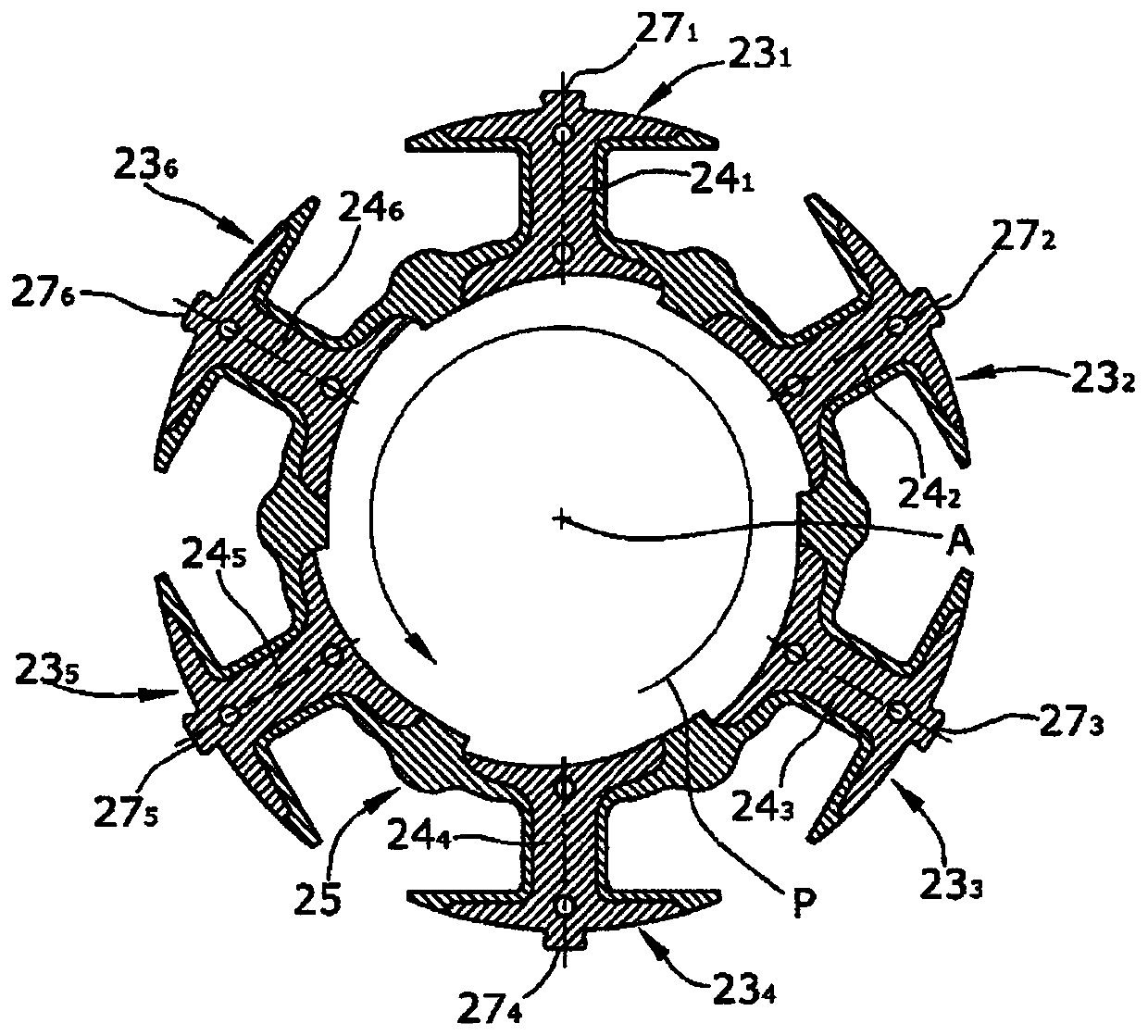

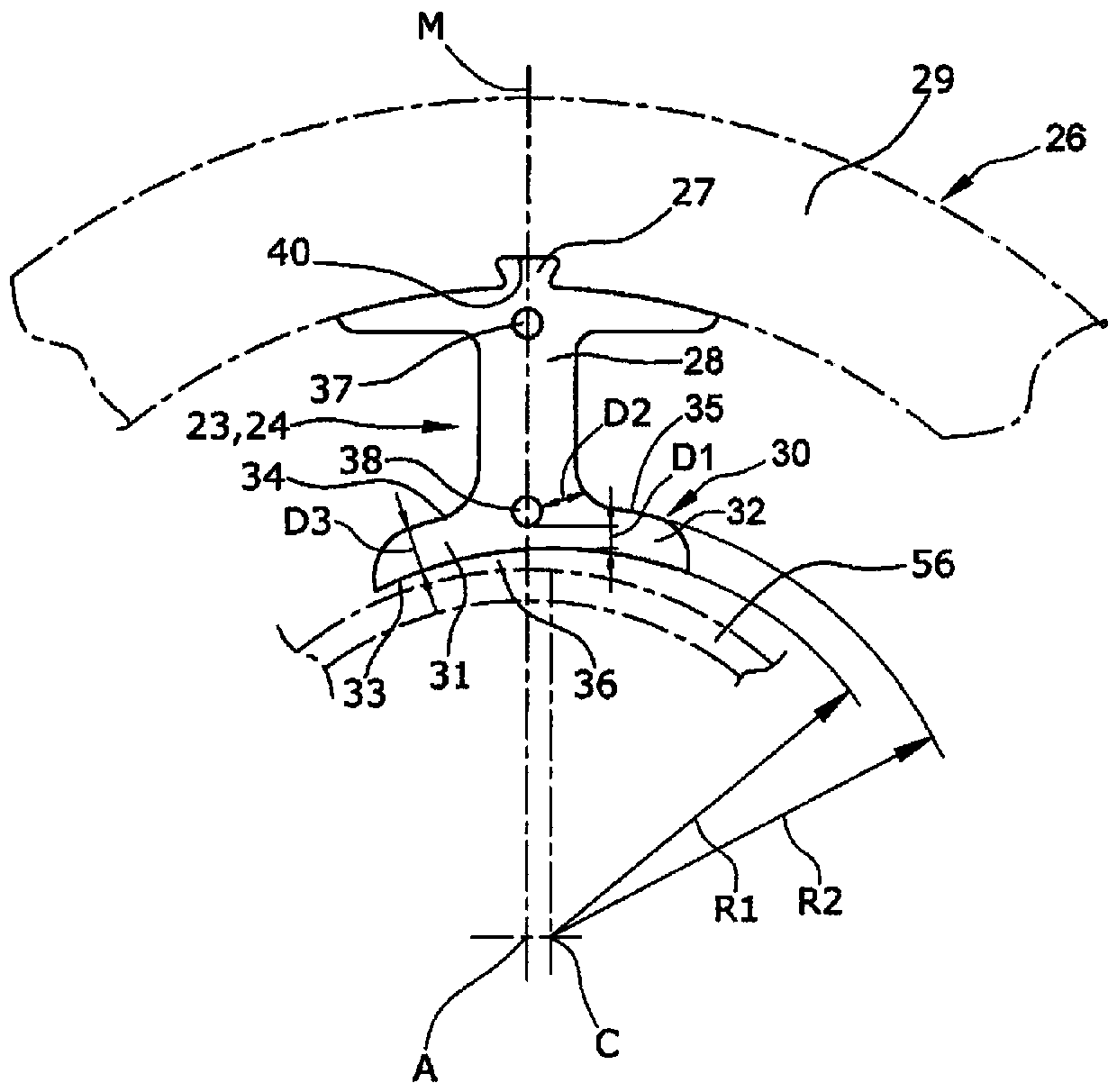

[0022] figure 2 A radial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com