Preparation technology of red jujube juice or concentrated clear red jujube juice with high water-soluble dietary fiber content

A dietary fiber and preparation technology, which is applied in the field of jujube juice production technology, can solve the problems of enzyme damage, difficulty in storage, long boiling time, etc., and achieve the effects of improving dietary fiber composition, reliable production technology, and mature and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

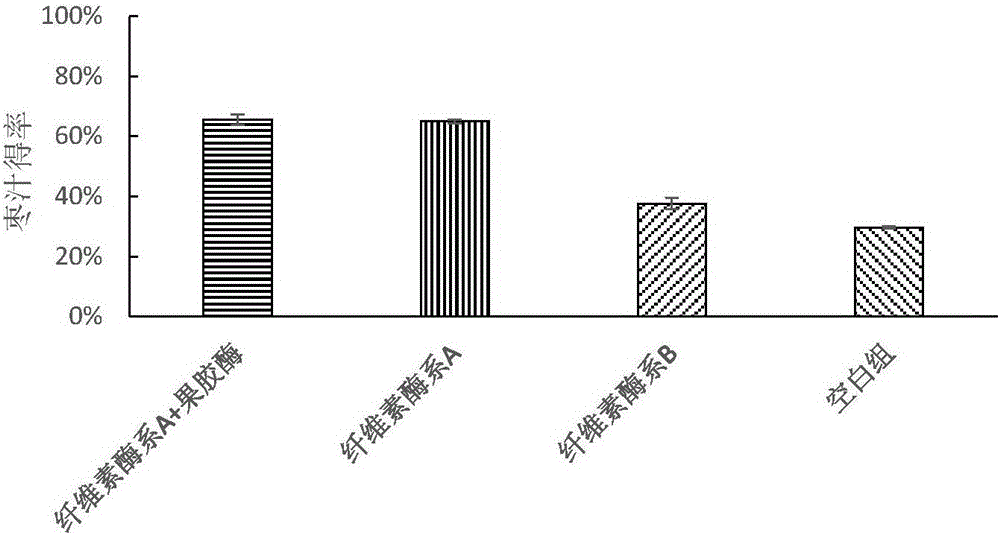

[0052] Take by weighing 1 kilogram of Leling Jinsixiaozao respectively, then clean the dust, mud, microorganisms and other impurities on the surface of the red jujube raw material with clear water that meets the drinking water standard, to ensure the hygienic requirements of the process; Add 2.4 times the quality of pure water, pre-boil at 75°C for 1 hour; beat. Add 1 times the mass of purified water for cooling. The jujube juice is prepared at a concentration of 15% (mass / volume). Enzymolysis starts at about 40°C; use compound cellulase system A and pectinase powder for enzymolysis, the addition amount is 5000U / kg dry jujube respectively; fully stir the enzymolysis at 45°C for 5 hours, pass through 5 Mesh, 10 mesh, 20 mesh, 60 mesh sieve (without mechanical pressure), fully separate jujube skin and jujube core from jujube juice. The sieved jujube juice is sent to a centrifuge for separation and clarification, and the clarified jujube juice is obtained under the centrifugal ...

Embodiment 2

[0059] A preparation process for jujube clear juice containing high water-soluble dietary fiber and red jujube concentrated clear juice comprises the following steps:

[0060] (1) Selection and cleaning:

[0061] Select 1 kg of bright-colored Leling Jinsixiaozao dried dates, without mildew and deterioration and other miscellaneous fruits; then use clean water that meets the drinking water standard to clean the dust, mud, microorganisms and other substances on the surface of the raw materials of the red dates Impurities to ensure the hygienic requirements of the process.

[0062] (2) Precooking at medium temperature, pitting, beating, peeling:

[0063] Add 2.4 times the weight of pure water to the dried jujube, pre-cook at 60-80°C for 0.25 hour; use a beater to preliminarily break the jujube, remove the core, further beat and peel the jujube.

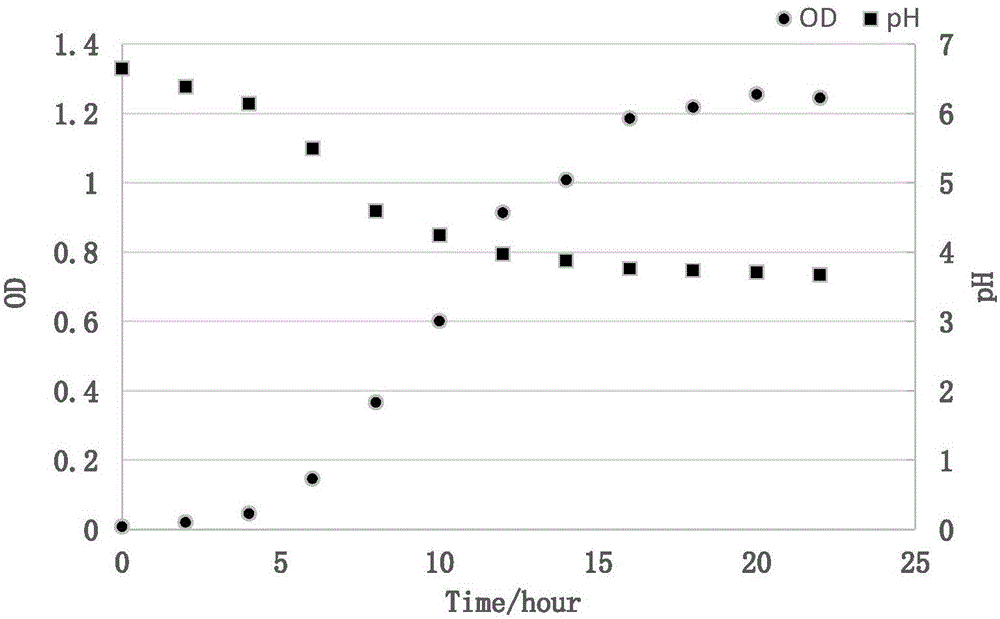

[0064] (3) Initial enzymatic hydrolysis: add 0.5 times the mass of pure water to cool, add 1000 U of pectinase per kilogram of dried ...

Embodiment 3

[0094] A preparation process for jujube clear juice containing high water-soluble dietary fiber and red jujube concentrated clear juice comprises the following steps:

[0095] (1) Selection and cleaning:

[0096] Select 1 kg of brightly colored jujubes from Jiaxian County in northern Shaanxi, without mildew and deterioration and other miscellaneous fruits; Impurities to ensure the hygienic requirements of the process.

[0097] (2) Precooking at medium temperature, pitting, beating, peeling:

[0098] Add 1 to 2 times the weight of pure water to the fresh jujube, and pre-cook it at 60-80°C for 0.5 hours; use a beater to preliminarily break the jujube, remove the core, further beat and peel the jujube.

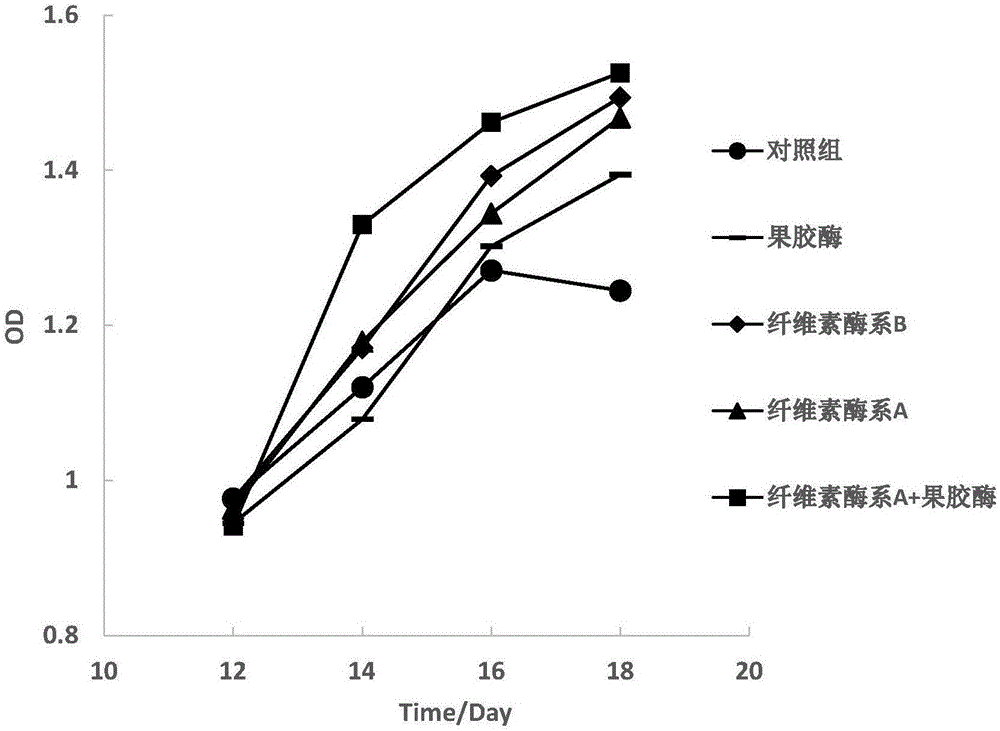

[0099] (3) Initial enzymatic hydrolysis: add 1 times the mass of pure water to cool, add 5000 U of pectinase per kilogram of fresh jujube, and use pectinase to carry out enzymatic hydrolysis at 50°C for 2 hours.

[0100] (4) Secondary enzymatic hydrolysis:

[0101] Separate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com