Pneumatic particle separator

A technology of particle separator and separation chamber, which is applied in the direction of climate sustainability, climate change adaptation, and devices with reverse axial direction of swirl flow, which can solve untimely reaction blockage, high temperature, inability to separate fine particle size, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

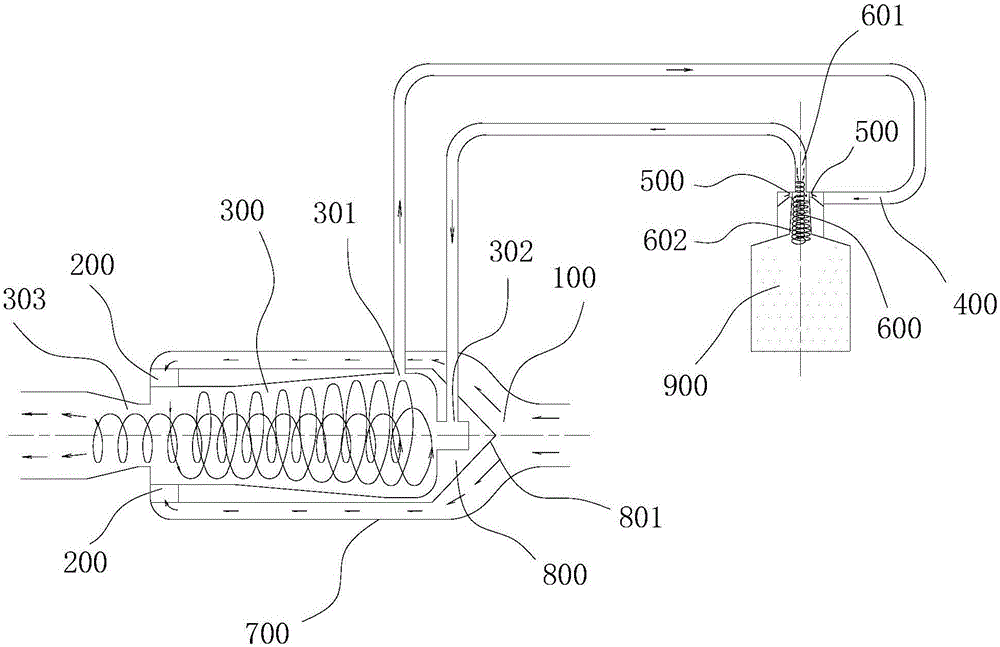

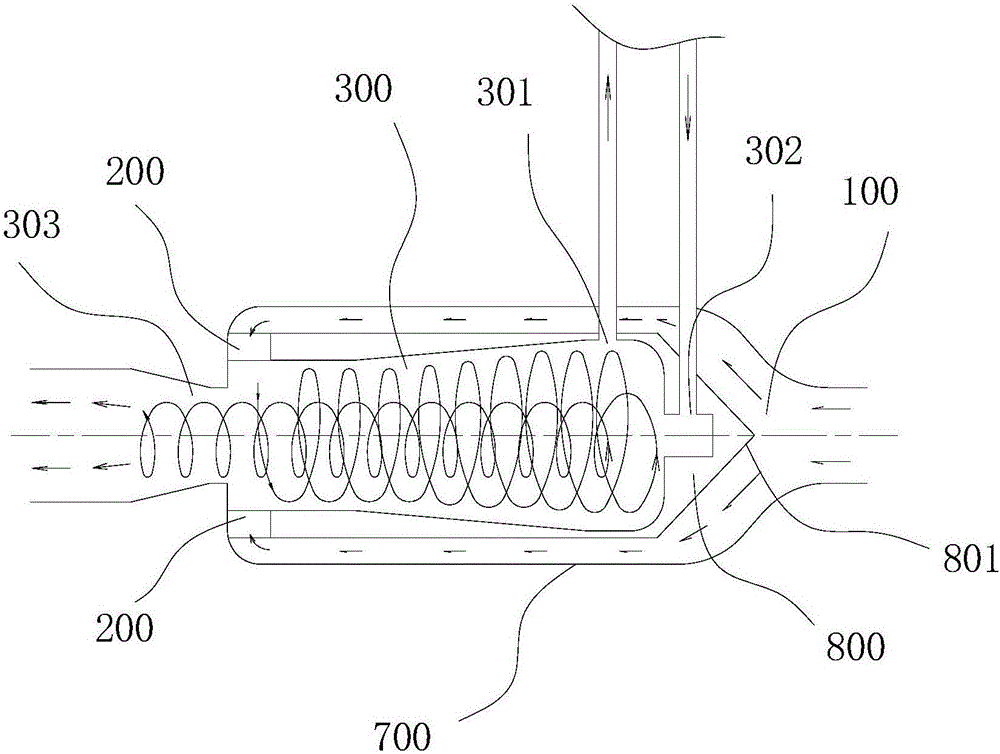

[0032] This embodiment provides a pneumatic particle separator, which can be used to separate the solid phase (such as dust) and the gas phase in the gas-solid mixture.

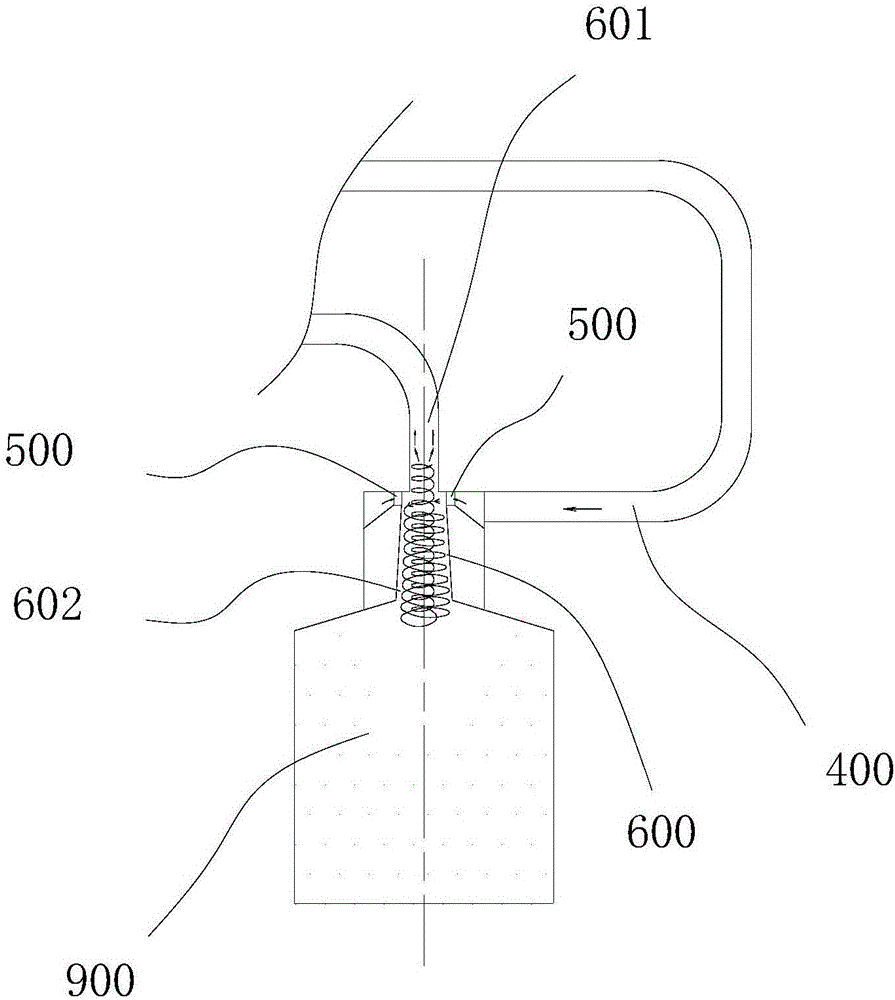

[0033] Please refer to Figure 1-3 , the pneumatic particle separator includes a main separation device and a dust collection device. The main separation device and the dust collection device can be cycled for multiple separation operations.

[0034] Specifically, the main separation device includes a first inlet channel 100 , a first cyclone 200 and a separation chamber 300 . This first cyclone 200 is installed on the first inlet channel 100, and the separation chamber 300 communicates with the first cyclone 200, and the first cyclone 200 can make the gas-solid mixture form a swirling flow (rotation) in the separation chamber 300 airflow). The swirling flow can make the solid phase and the gas phase rotate along different paths, the solid phase will rotate close to the wall of the separation chamber 300 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com