Glue dispenser stable in pressure

A technology of stable pressure and glue dispensing machine, applied in the field of glue dispensing machine, can solve the problems of unstable air pressure, small pressure, large cross-sectional area, etc., and achieve the effect of adjustable driving speed, stable pressure and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

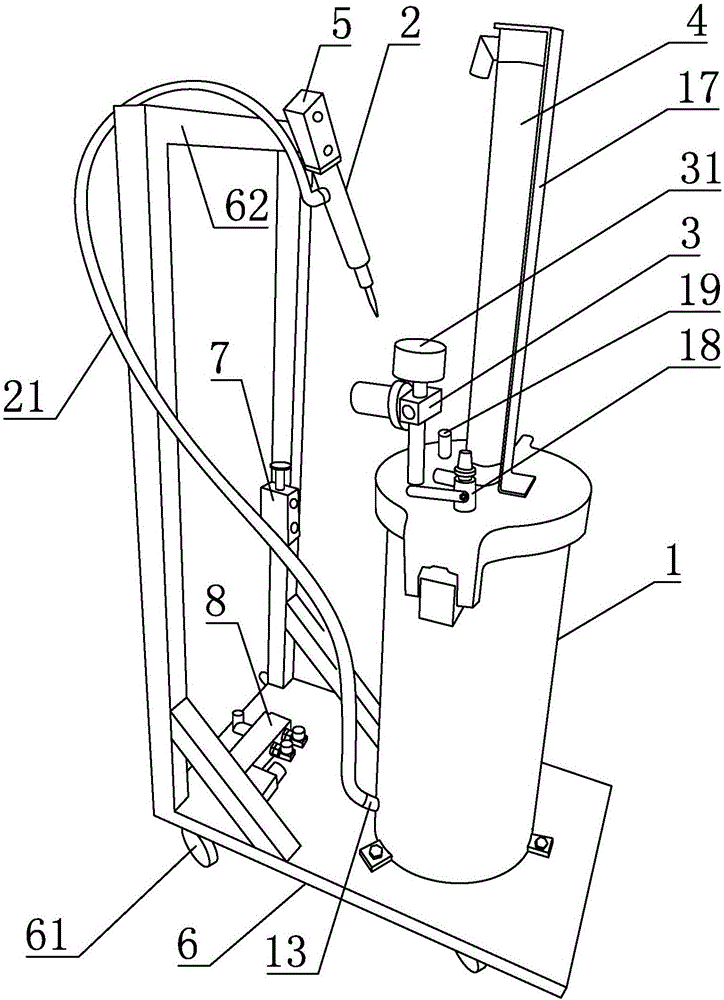

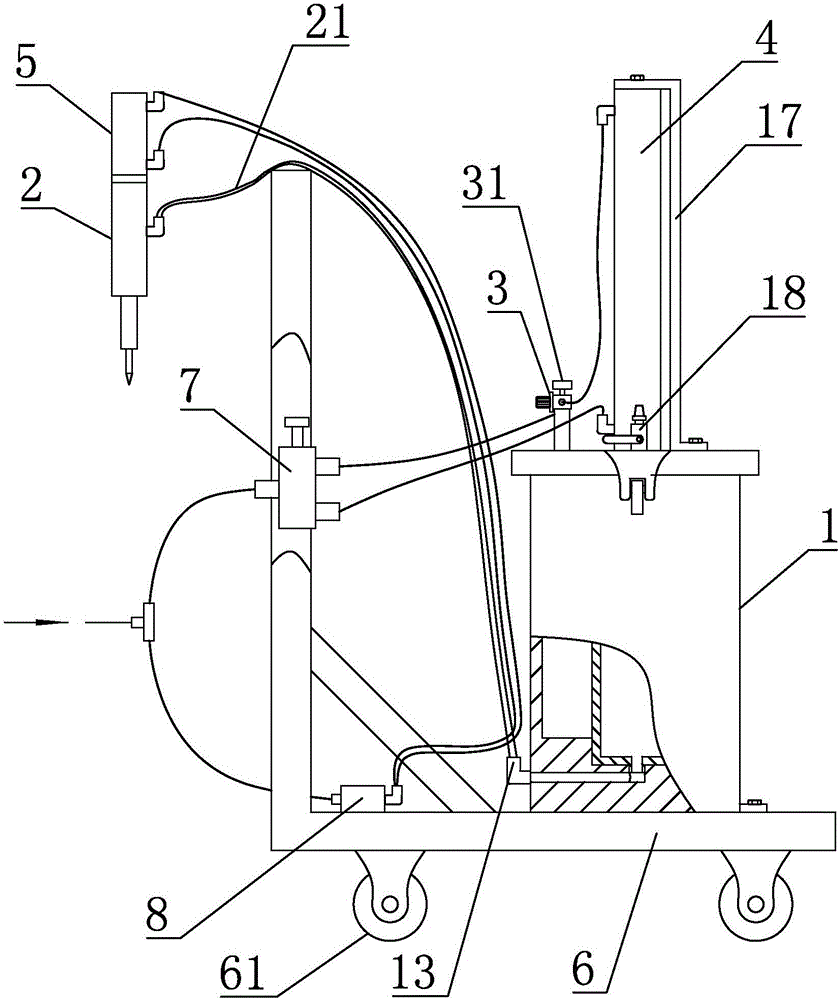

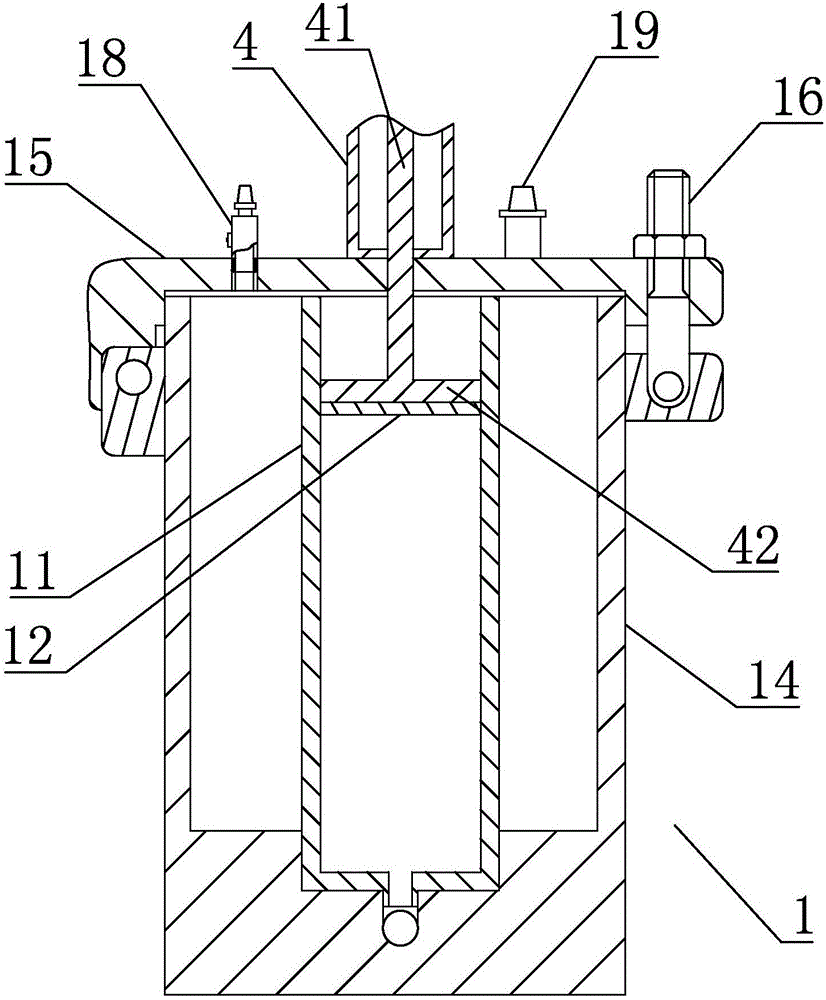

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] refer to figure 1 , a pressure-stabilized dispensing machine of the present invention includes an air source supplied by an air compressor, a material barrel 1 that can accommodate glue, and a dispensing gun 2. The material barrel 1 is a cylindrical long barrel, and its vertical Straight is installed on the movable trolley 6, and trolley 6 is a rectangular flat plate, and four movable wheels 61 are equipped with at its bottom, and wherein a movable wheel 61 is provided with braking device, and when parking, the foot brake device just Dolly 6 can be positioned to prevent it from moving or slipping away. Cart 6 one side is also provided with handrail 62, and handrail 62 is to comprise two columns, and the top of two columns is connected by a crossbeam, and the height of crossbeam is set to be flush with the waist of ordinary people, and hand-holding crossbeam can just...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com