Body-in-white workshop line fast-travel mechanism and its interaction method

An interactive method and a body-in-white technology, which is applied to the line-body fast-passing mechanism and its interaction field in a body-in-white workshop, can solve the problems of reduced response efficiency, inconvenience, and impact on the production and output of body-in-white, so as to improve work efficiency and reduce walking time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

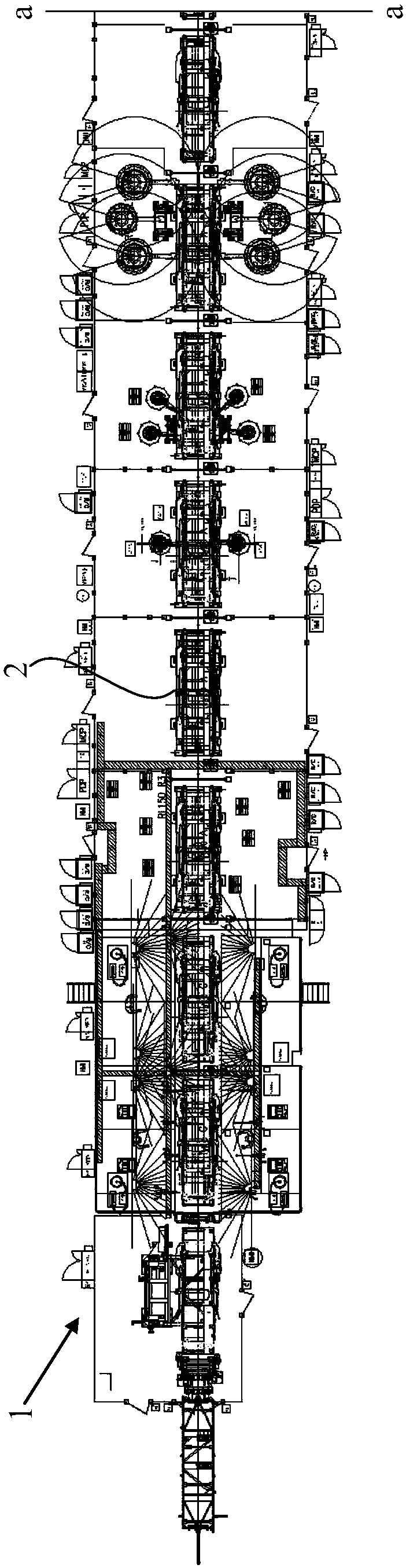

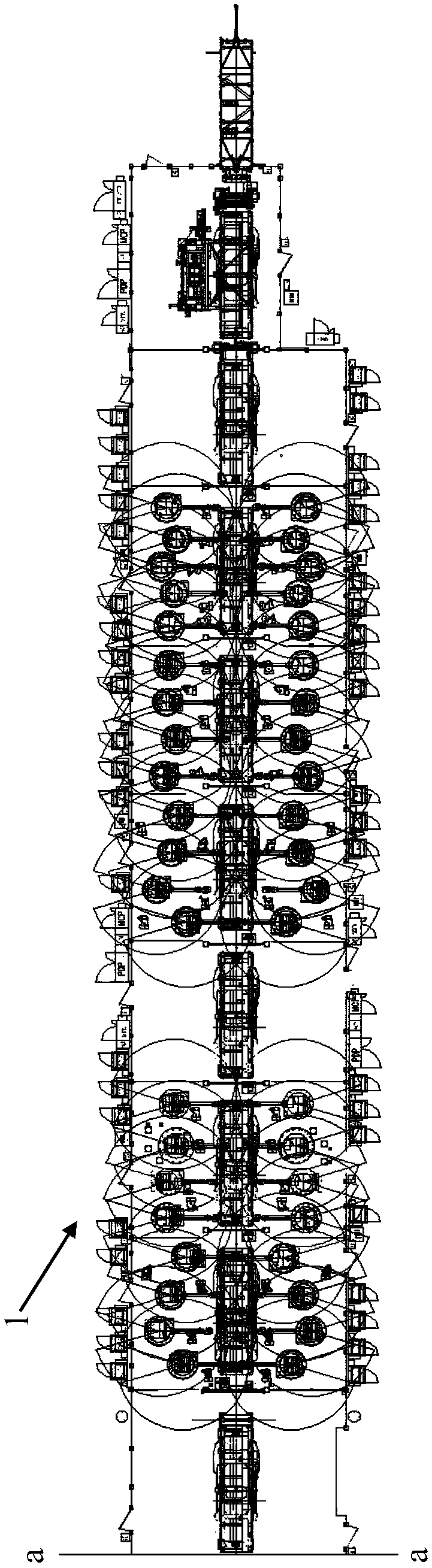

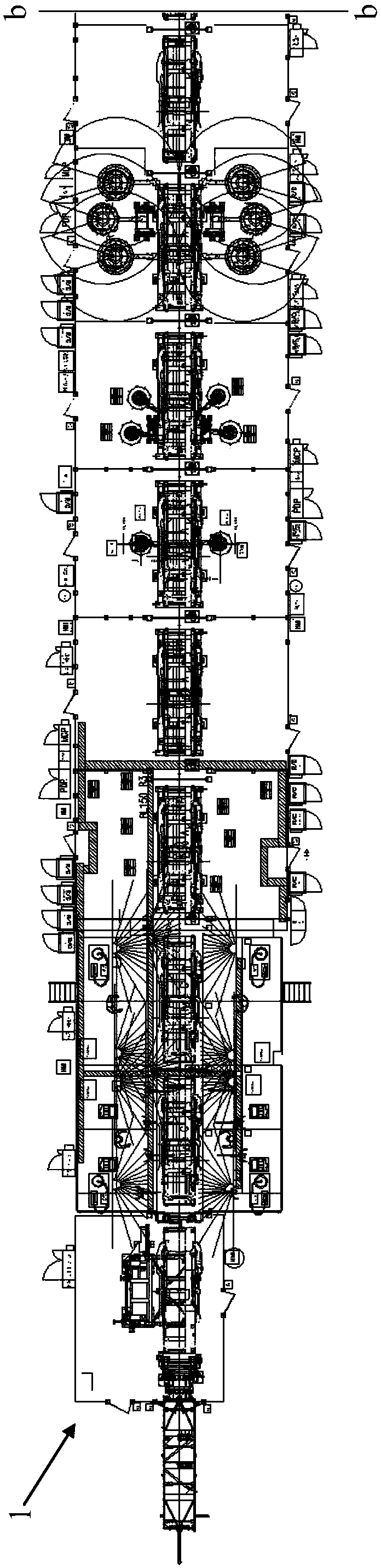

[0035] The body-in-white workshop line body rapid passage mechanism of the present invention is located at Figure 2A and 2B Between the two stations in the middle section of line body 1 shown, specifically as Figure 2B As shown in c, after zooming in as image 3 As shown, it is an aisle for people to pass horizontally.

[0036] The three-dimensional representation of the aisle is as follows Figure 4 As shown, guardrails 101 bent at right angles are respectively provided on both sides of the entrance at both ends of the corridor, and a safety door 102 is provided between the guardrails 101 at each end of the passage, and the fixed side of the safety door 102 is pivotally connected to the corner of the guardrail 101 on one side. The movable side of the safety door 102 can be locked at the corner of the guardrail on the other side through the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com