Cathode Steel Rod Full Section Welding Machine

A cathode steel rod and full-section technology, which is applied in the field of electrolytic aluminum, can solve the problems of low welding efficiency, high welding cost, and low degree of automation, and achieve the effects of increasing welding temperature, improving welding quality, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

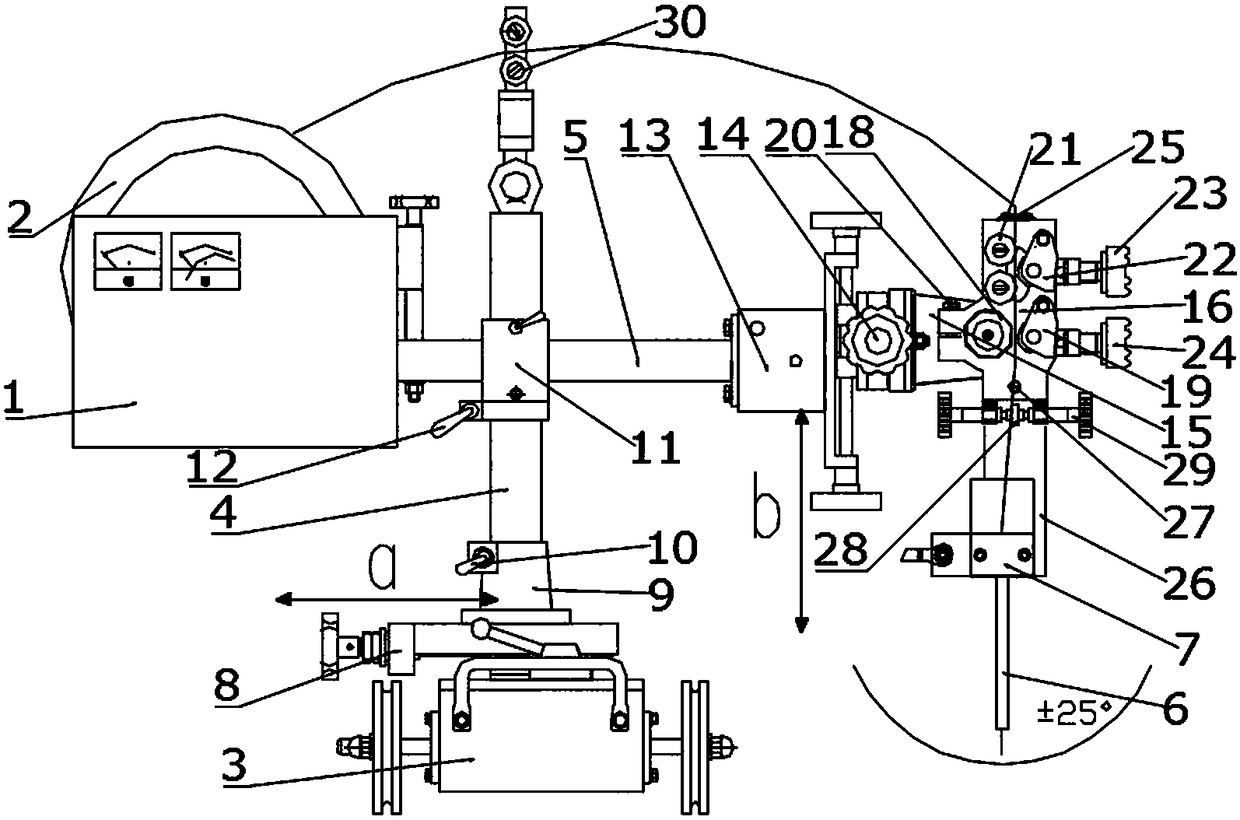

[0044] A full-section welding machine for cathode steel rods, including a mobile trolley 3, a column 4, a beam 5, a control box 1 and a machine head, the column 4 is rotatably arranged on the mobile trolley 3, and the beam 5 is vertically connected by a locking mechanism On the column 4; the control box 1 is fixed on one end of the beam 5, the machine head includes a wire feeding mechanism, a melting nozzle 6, a melting nozzle clip 7 and a fine-tuning mechanism for the melting nozzle 6, and the wire feeding mechanism is fixed on the beam 5 The other end of the melting nozzle 6 is connected to the wire feeding mechanism through the fine adjustment mechanism of the melting nozzle 6, and the fine adjustment mechanism of the melting nozzle 6 is used to control the swing of the melting nozzle 6.

[0045] In this embodiment, the mobile trolley 3 adopts a building block structure, and the wheels of the mobile trolley 3 are wrapped with high-temperature-resistant rubber on the outside ...

Embodiment 2

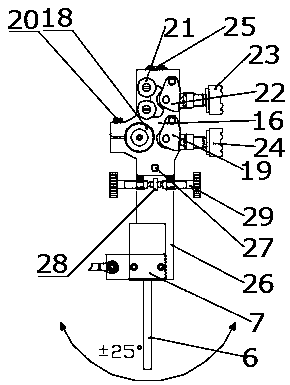

[0058] A full-section welding machine for cathode steel rods, including a mobile trolley 3, a column 4, a beam 5, a control box 1 and a machine head, the column 4 is rotatably arranged on the mobile trolley 3, and the beam 5 is vertically connected by a locking mechanism On the column 4; the control box 1 is fixed on one end of the beam 5, the machine head includes a wire feeding mechanism, a melting nozzle 6, a melting nozzle clip 7 and a fine-tuning mechanism for the melting nozzle 6, and the wire feeding mechanism is fixed on the beam 5 The other end of the melting nozzle 6 is connected to the wire feeding mechanism through the fine adjustment mechanism of the melting nozzle 6, and the fine adjustment mechanism of the melting nozzle 6 is used to control the swing of the melting nozzle 6.

[0059] In this embodiment, an oscillator 13 is fixedly connected to the end of the beam 5 , and the wire feeding mechanism is connected to the beam 5 through the oscillator 13 . Wherein, ...

Embodiment 3

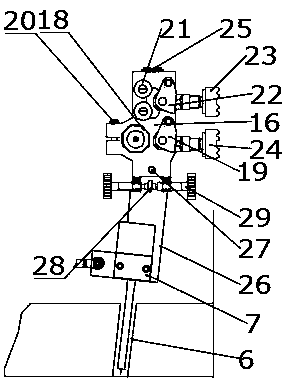

[0062] A full-section welding machine for cathode steel rods, comprising a mobile trolley 3, a column 4, a beam 5, a control box 1 and a machine head, the column 4 is rotatably arranged on the mobile trolley 3, and the beam 5 is vertically connected by a locking mechanism On the column 4; the control box 1 is fixed on one end of the beam 5, the machine head includes a wire feeding mechanism, a melting nozzle 6, a melting nozzle clip 7 and a fine-tuning mechanism for the melting nozzle 6, and the wire feeding mechanism is fixed on the beam 5 The other end of the melting nozzle 6 is connected to the wire feeding mechanism through the fine adjustment mechanism of the melting nozzle 6, and the fine adjustment mechanism of the melting nozzle 6 is used to control the swing of the melting nozzle 6.

[0063] In this embodiment, the end of the beam 5 is also provided with a swinger 13 and a cross slide 14, the swinger 13 is fixedly connected with the beam 5, the cross slide 14 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com