Printing machine vertical alignment online detection and fault diagnosis method and device

A technology for fault diagnosis and printing machines, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of precision limitation, failure to consider the influence, and deviation between the measured value and the actual value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

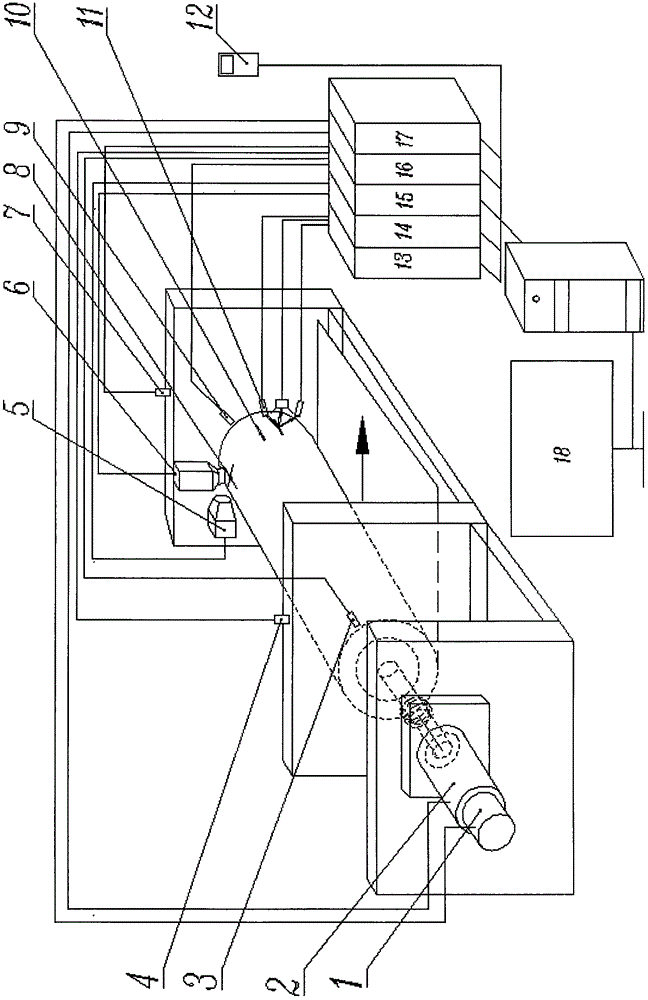

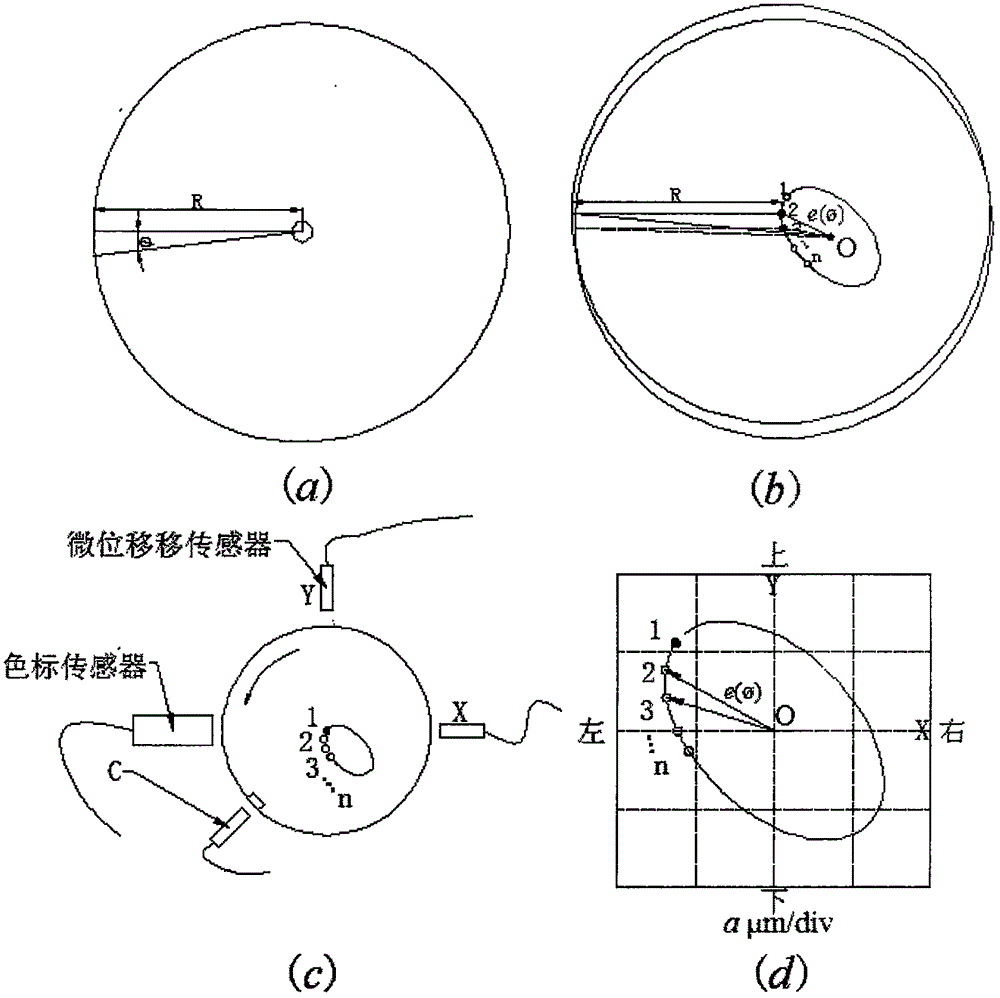

[0044] Schematic diagram of overprint detection and fault diagnosis device figure 1As shown, the components of the device include: encoder 1, servo motor 2, first micro-displacement sensor 3, second micro-displacement sensor 9, first acceleration sensor 4, second acceleration sensor 7, stroboscope 5, CCD image Sensor 6, cross color mark 8, printing cylinder 10, color mark sensor 11, temperature and humidity sensor 12, color mark signal acquisition instrument 13, CCD image acquisition instrument 14, vibration signal acquisition instrument 15, servo driver 16, motion controller 17, Host computer 18.

[0045] The structure of the mechanical part of the device is shown in Figure 4 .

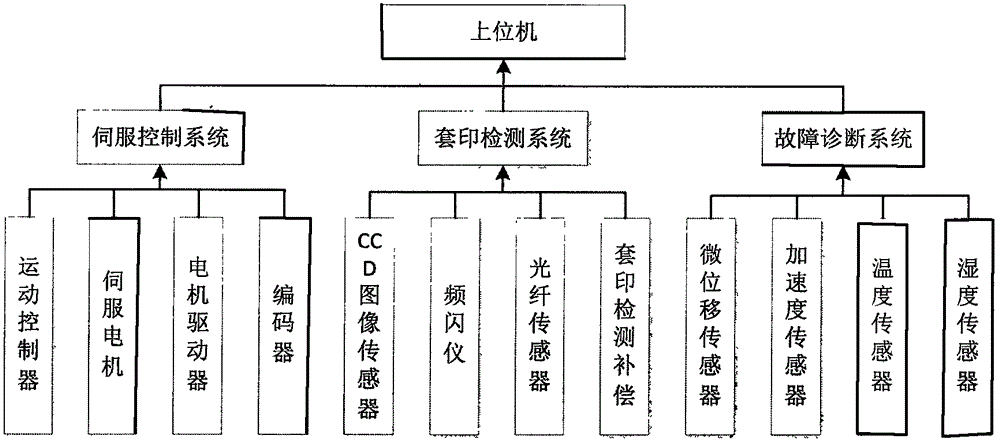

[0046] The system consists of figure 2 As shown, including: servo control system, overprint detection system, and fault diagnosis system. Specifically inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap