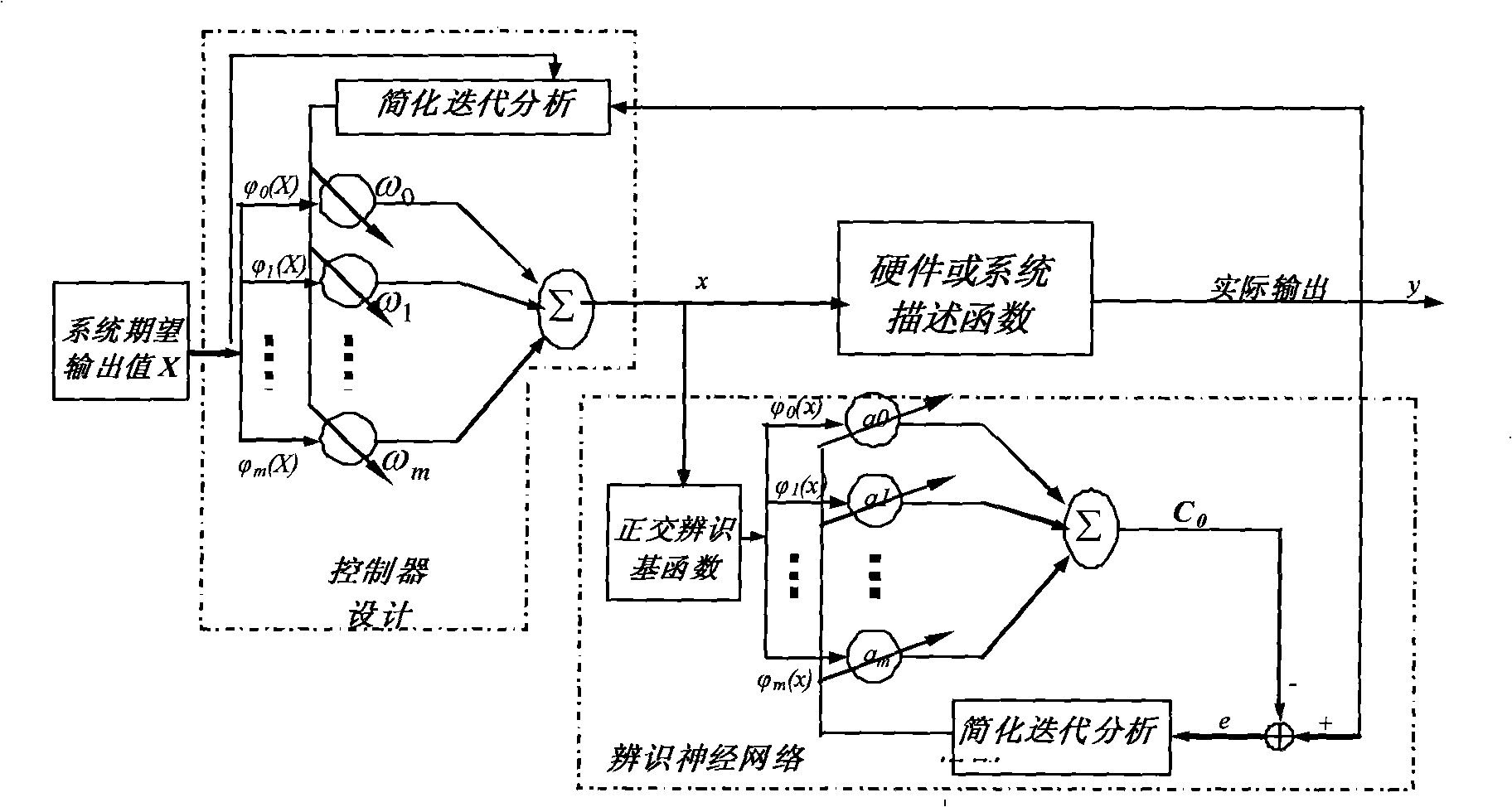

System controller structure of neural net and system identification structure

A technology of neural network control and system controller, applied in the direction of adaptive control, general control system, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0071] Such as figure 2 , for example, there is a field-level analog output unit whose function is to perform analog output according to the received control output command, which is usually the output value sent by the upper control bus, such as sending 0-20mA, 4-20mA, 0-5V Such conventional analog output values.

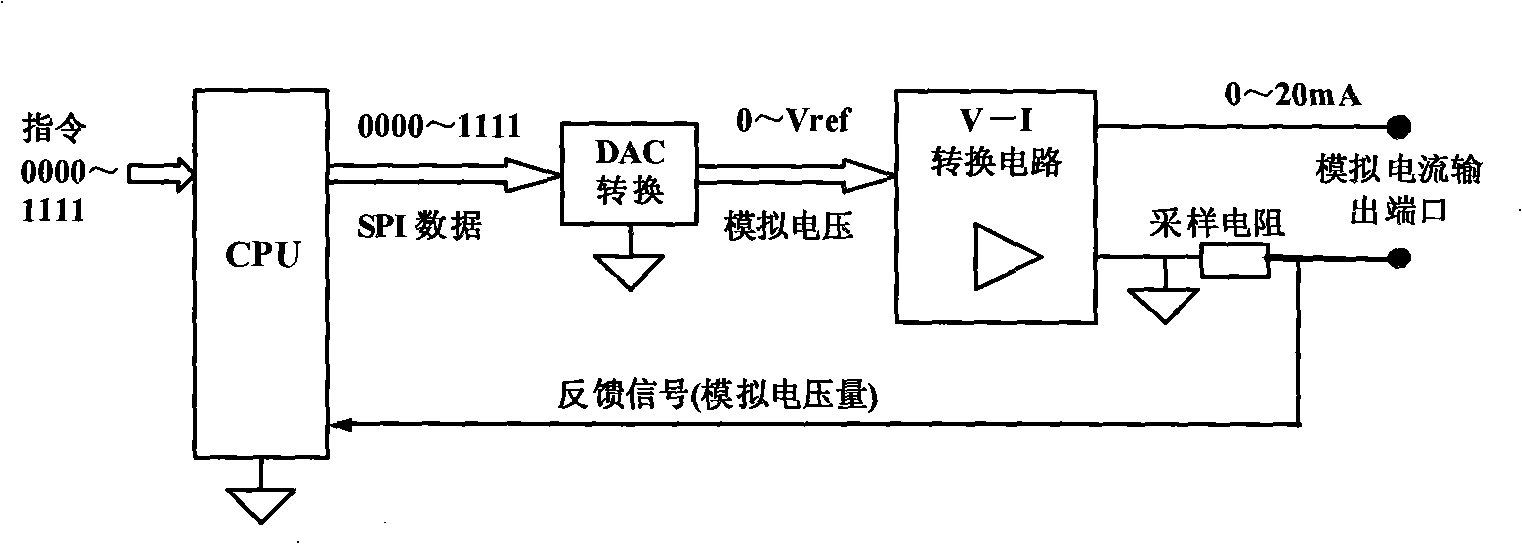

[0072] Due to specific component errors, performance aging, temperature drift and other issues, the electrical parameters of the hardware have changed, and the error between the output signal and the expected value of the control exceeds the requirements. It is required to design a software identification structure. When necessary, through a button or key, start the neural network verification program, and use software to optimize and change control parameters and improve control accuracy.

[0073] For example, if the hardware of a current analog output channel outputs 0-20mA current according to the input command code 0000-1111, its structure is as follows: im...

example 2

[0089] For many control systems, due to the many intermediate links involved, the error is difficult to control. After the completion of the system, the accuracy of the entire system needs to be debugged. figure 1 The advanced artificial neural network structure can realize the automatic adjustment of system precision, saving a lot of manpower, material resources and time.

[0090] For example, assume that Figure 7 The centrifugal pump constant pressure control system is a simple single-loop control system. The pressure sensor PT installed on the outlet pipeline of the centrifugal pump converts the outlet pressure of the centrifugal pump into a voltage signal, which is amplified by the amplifier and output to the PC industrial control computer. After the PC compares the pressure signal with the pressure given value, it needs to set the network weight according to the According to the adjustment law, the excitation signal of frequency conversion speed regulation is output, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com