U-shaped groove body for bookbinding, manufacturing method and application thereof

A technology of U-shaped groove and formed body, which is applied in binding, book binding, book case for binding, etc., can solve the problems of falling off, page by page, and single page of text, etc. The effect of bomb impact and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

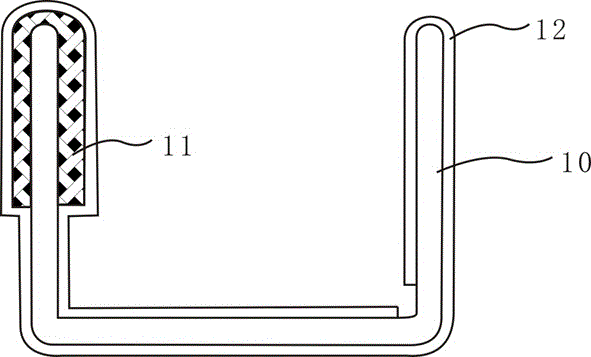

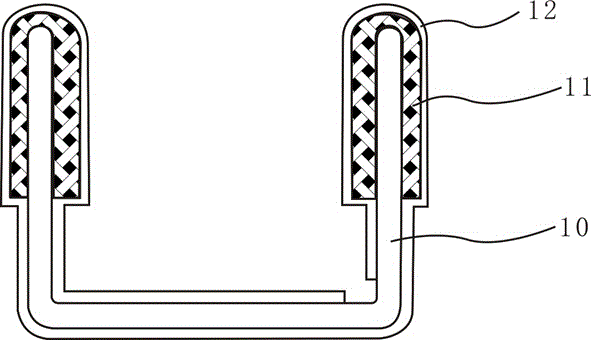

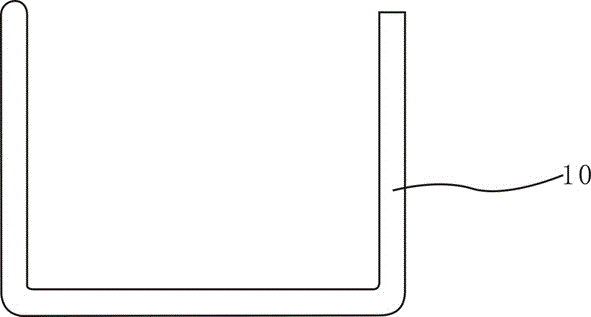

[0036] see Figure 1-2 , the binding U-shaped trough body of the present invention comprises a U-shaped trough body 10 made of steel material, wherein one or both upper ends of the U-shaped trough main body 10 are wrapped with adhesive tape 11 for preventing falling off; if the U-shaped trough main body One of the upper ends of 10 is wrapped with the anti-falling tape 11 to form a unilateral wrapping molded body. If both upper ends of the U-shaped groove main body 10 are wrapped around the anti-falling tape 11, a double-sided wrapped molded body is formed. ; The outer surface of the unilaterally wrapped molding body or double-sided wrapped molding body is wrapped with the wrapper 12 to form the U-shaped groove body for binding.

[0037] In this embodiment, the U-shaped groove main body 10 is formed by stamping a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com