Spinning progressive forming device

A technology of progressive forming and pressing rod, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of sheet metal springback, low processing efficiency, instability, etc., to reduce the springback effect, improve the forming efficiency, The effect of increasing the forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

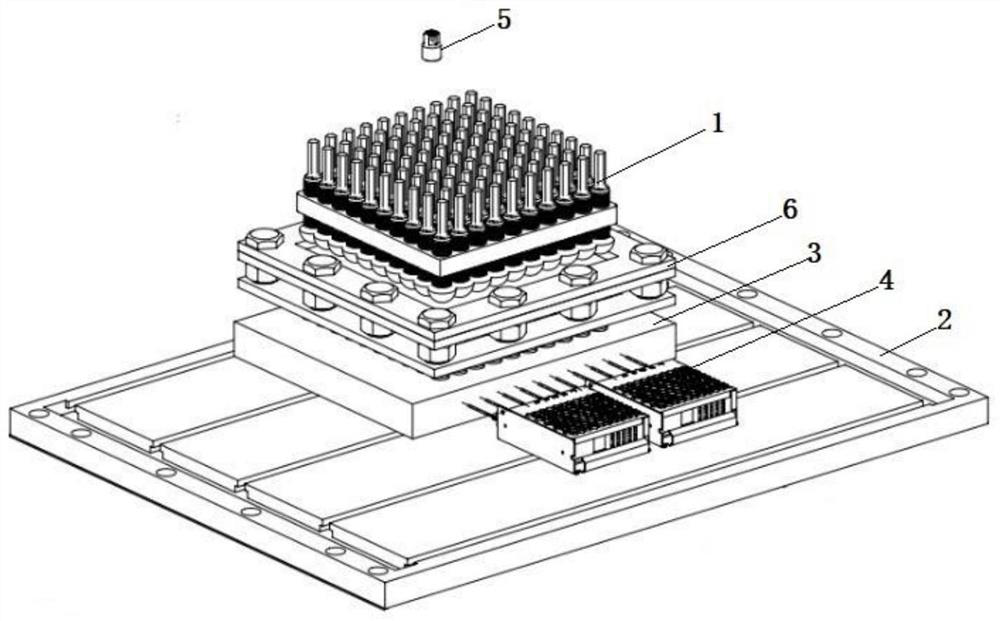

[0039] A spinning incremental forming device, such as figure 1 As shown, it includes a spinning assembly 1 , a workbench 2 , a thermal elastic assembly 3 and a pressing assembly 6 .

[0040] In this embodiment, the workbench 2 is configured as a flat plate made of cast iron. Since the cast iron has the ability to absorb machine vibration, the precision of forming the metal sheet can be improved.

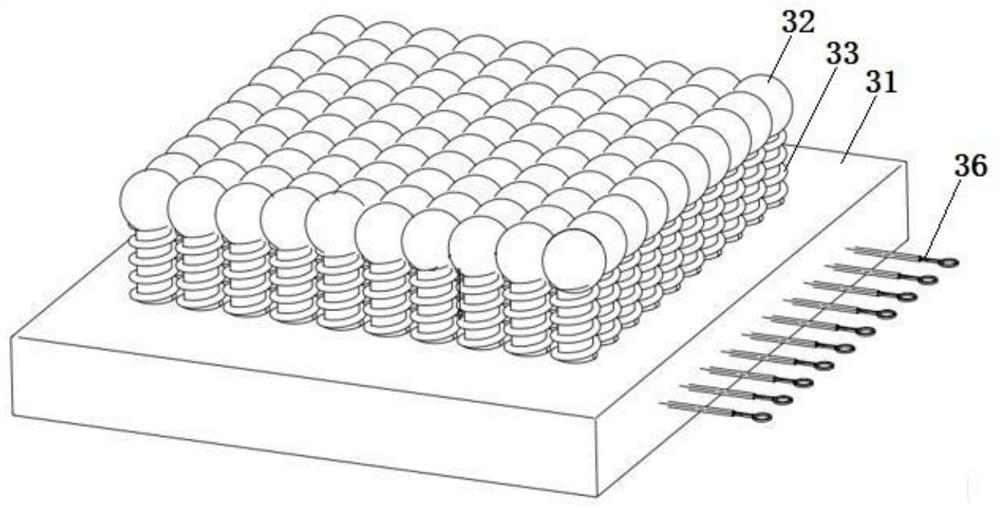

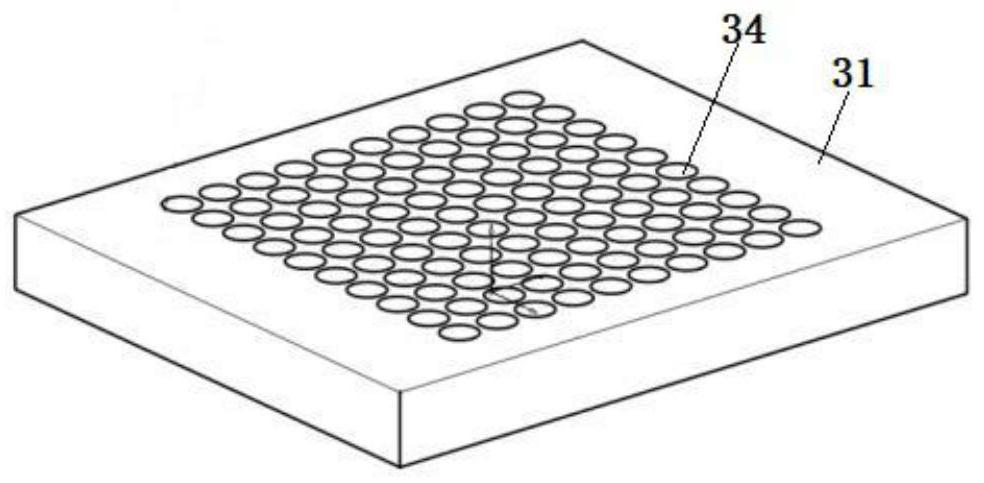

[0041] In this example, if Figure 2-4 As shown, the thermal elastic assembly 3 includes a thermal elastic plate 31 and a plurality of heating ball heads 32 . The thermoelastic plate 31 is a flat plate, which is placed or fixed on the workbench 2. The central part of the thermoelastic plate 31 is provided with a thermoelastic area, and the above-mentioned plurality of heating ball heads 32 are evenly distributed in the thermoelastic area. Specifically, Preferably, a plurality of elastic reset members 33 are arranged in an evenly distributed manner on the thermal elastic region, and...

Embodiment 2

[0050] It differs from Embodiment 1 in that: in this embodiment, the thermoelastic assembly 3 also includes a hollow rigid guide post 37, such as Figure 4 As shown, and each coil spring is equipped with a rigid guide column 37, the rigid guide column 37 passes through the coil spring, that is, the rigid guide column 37 is also arranged in the placement hole 34, and the top end of the rigid guide column 37 is also fixed It is connected to the heating ball head 32, so as to guide and restrict the coil spring during telescopic movement, and prevent the coil spring from being affected by the elastic effect due to deviation or lodging. Correspondingly, the above-mentioned wire 36 passes through the hollow structure of the rigid guide post 37 .

Embodiment 3

[0052] The difference between it and Embodiment 1 is: in this embodiment, if Figure 5 As shown, the pressing assembly 6 is set to further include a support plate 63, the support plate 63 is annular, the support plate 63 is placed on the top surface of the thermal elastic plate 3 and the frame of the support plate 63 is arranged around the thermal elastic area, and at the same time, the support plate 63 is located Below the two pressing plates 61 , so as to provide support for the bolts 62 through the frame of the support plate 63 .

[0053] Such an arrangement enables the overall stability to be improved by the support plate 63 .

[0054] In addition, threaded holes can also be provided on the frame of the support plate 63 so that the studs of the bolts 62 can be screwed therein, so that the press assembly 6 is connected and fixed as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com