Retaining Rings for Chemical Mechanical Polishing

A technology for retaining rings and polishing pads, which is used in grinding machine tools, manufacturing tools, grinding devices, etc., can solve the problem of easy wear and tear of retaining rings, and achieve the effect of reducing the rebound effect of the pad and improving the polishing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

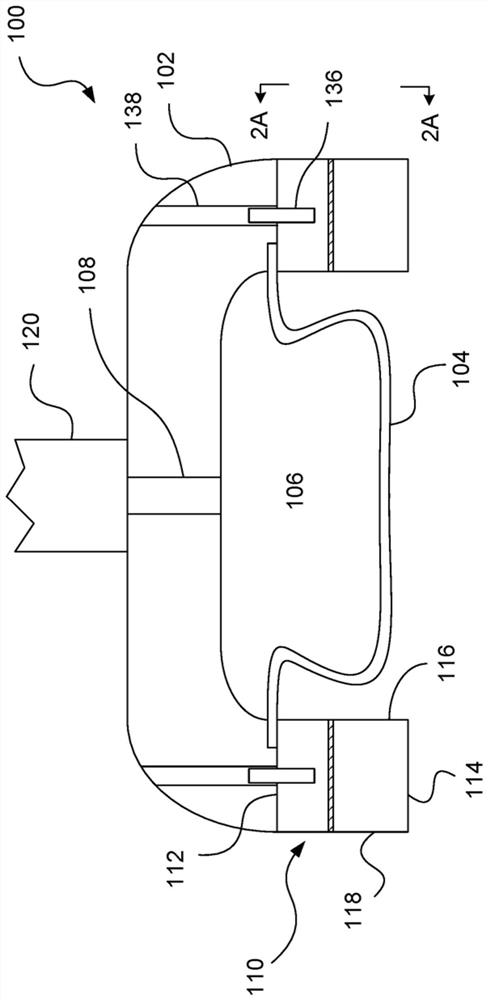

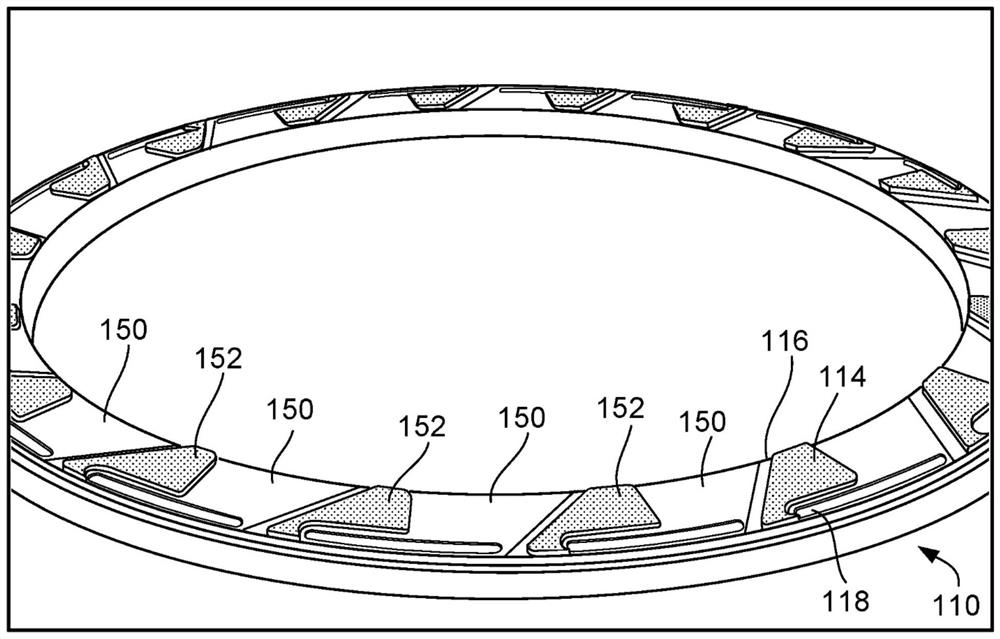

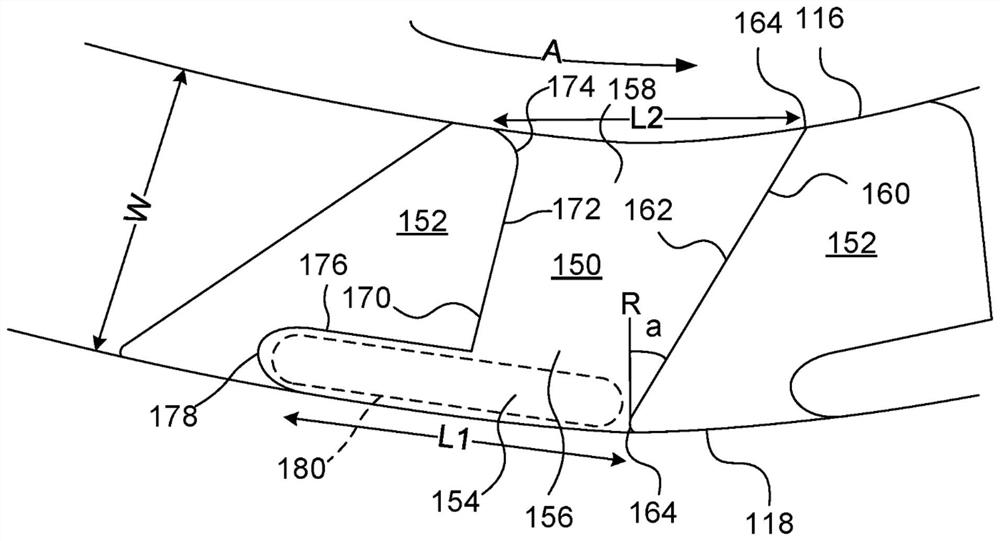

[0018] A retaining ring may be used to press against the surface of the polishing pad in the area surrounding the substrate. Specifically, the retaining ring needs to be pressed with sufficient force so that the substrate does not accidentally slide under the ring and effectively catches the substrate. The retaining ring can also be used to compress the polishing pad near the edge of the substrate and thus affect the polishing rate at the edge of the substrate. However, when the pad is compressed in this manner, the elasticity of the polishing pad, along with the relative motion between the pad and the retaining ring, can lead to a "pad springback effect," which can increase radial non-uniformity.

[0019] Two techniques can be used to reduce pad springback effects. First, by reducing the contact area of the retaining ring against the polishing pad, less of the pad is squeezed and thus less of the substrate is subject to pad bounce. Second, certain shapes of contact area a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com