New composite wire saw winding equipment

A composite wire and equipment technology, which is applied in the field of new composite wire saw winding equipment, can solve the problems of uncontrollable winding process and inability to set the winding gap of outer wires, so as to improve cutting efficiency and slice quality, controllable winding process, reduce The effect of rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

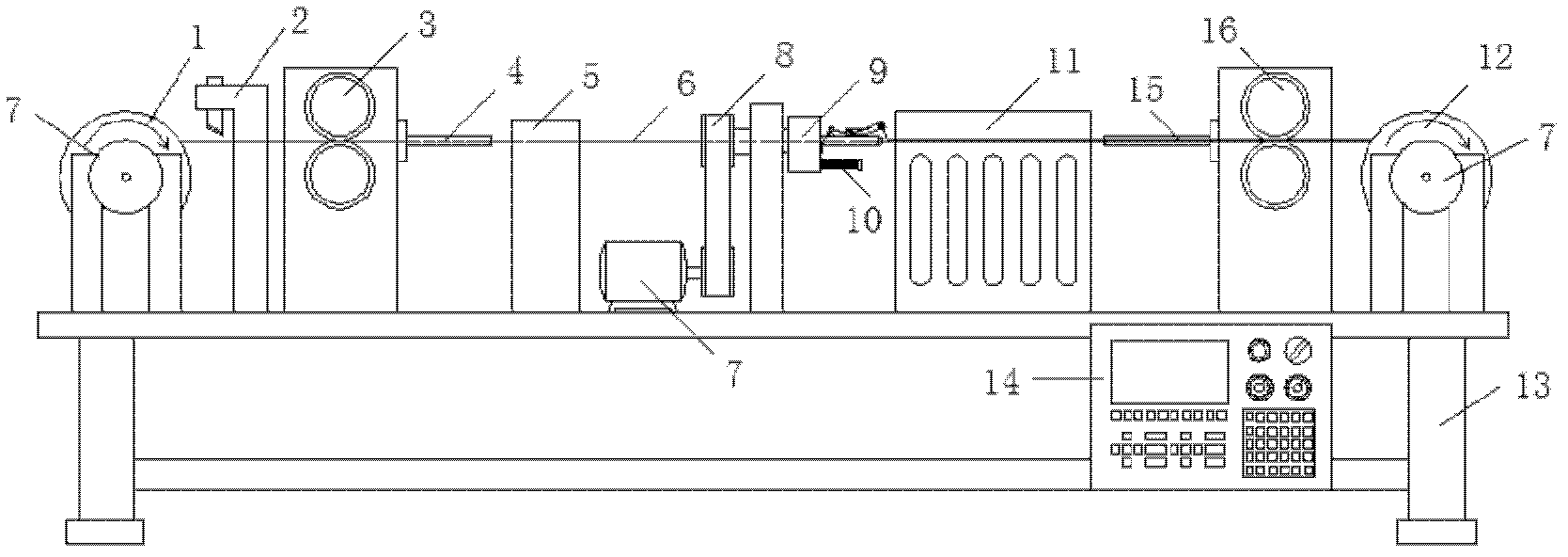

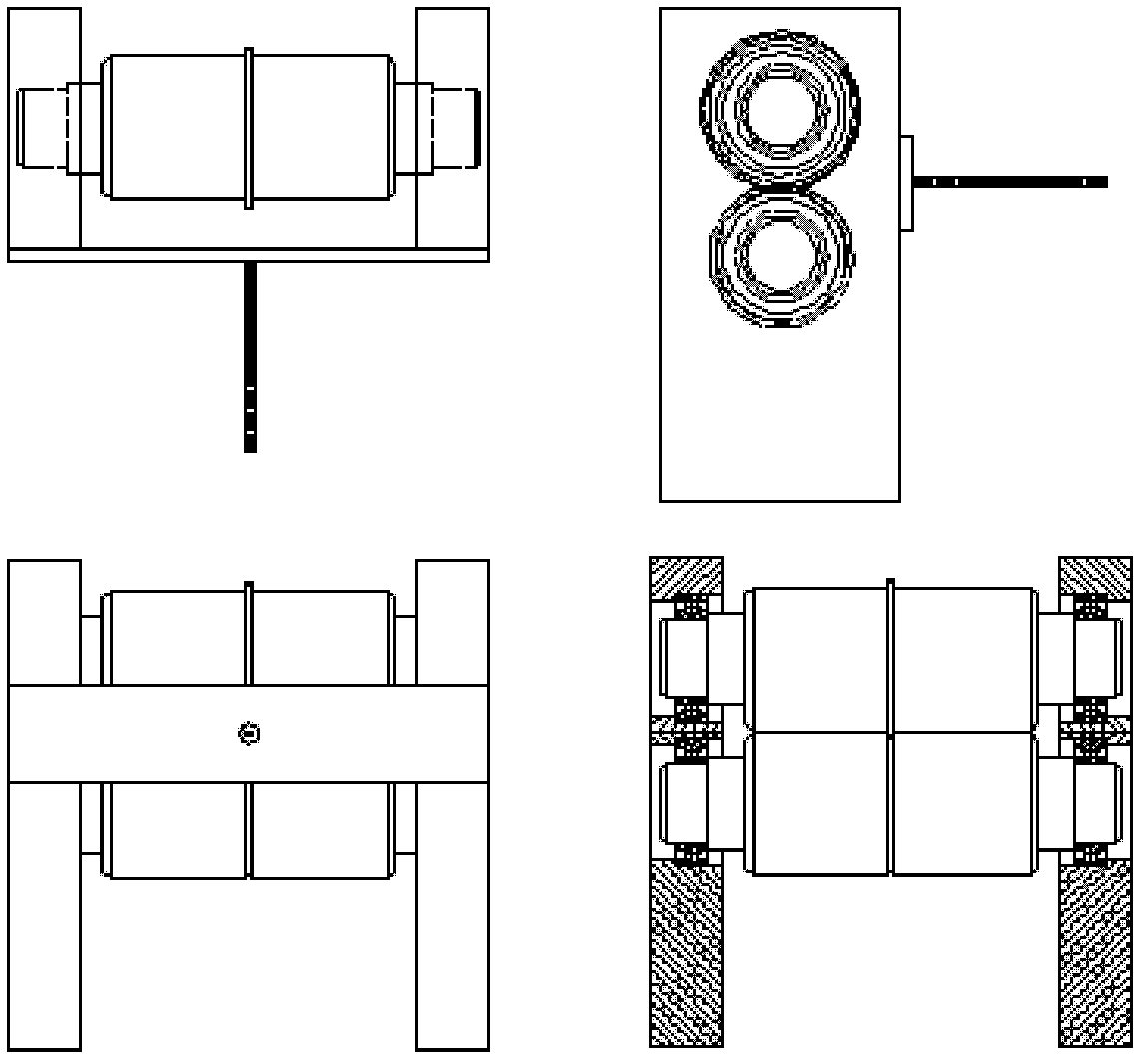

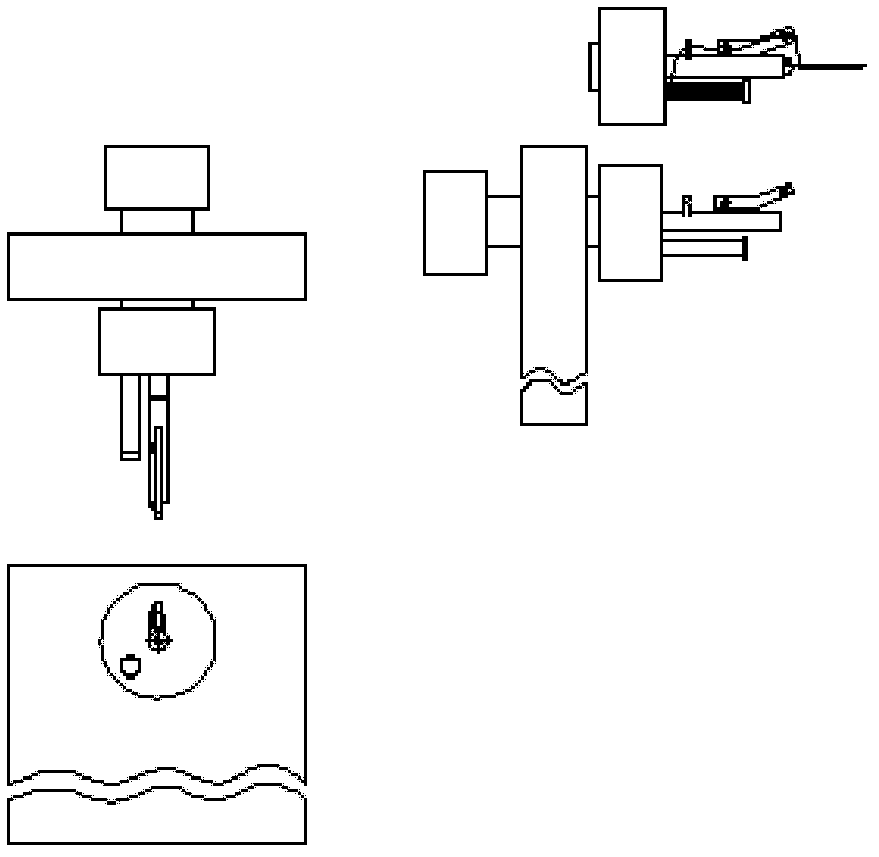

[0018] refer to Figure 1 to Figure 4 , a new type of compound wire saw winding equipment, including an equipment base 13, a servo motor 7 installed at both ends of the equipment base 13, a pay-off reel 1 and a take-up reel 12 connected to the servo motor 7, and a breaker Thread cutter 2, first tensioning reel head 3, second tensioning reel head 16, first conduit 4, second conduit 15, detachable dipping tank 5, winding arm driven by timing pulley 8 9 and a controller 14, the synchronous pulley 8 is connected with a servo motor 7; the control end of the servo motor 7 is connected with the controller 14; The first tensioner head 3, the dipping tank 5 coated with glue on the surface, enters the winding arm 9 to rotate and wind; the wound wire saw passes through the second tensioner head 16 and winds to On the take-up reel 12; the outlet end of the first tensioner head 3 is provided with the first wire conduit 4, and the inlet end of the second tensioner head 16 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com