Disassembling and assembling machine for vehicle-mounted tire

A tire changer and tire disassembly technology, applied in tire installation, road vehicle tires, tire parts, etc., can solve the problems of high manufacturing cost, complicated disassembly process, large space occupied by tire changer, etc. To achieve the effect of ensuring the use function, reducing the manufacturing cost and reducing the three-dimensional occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

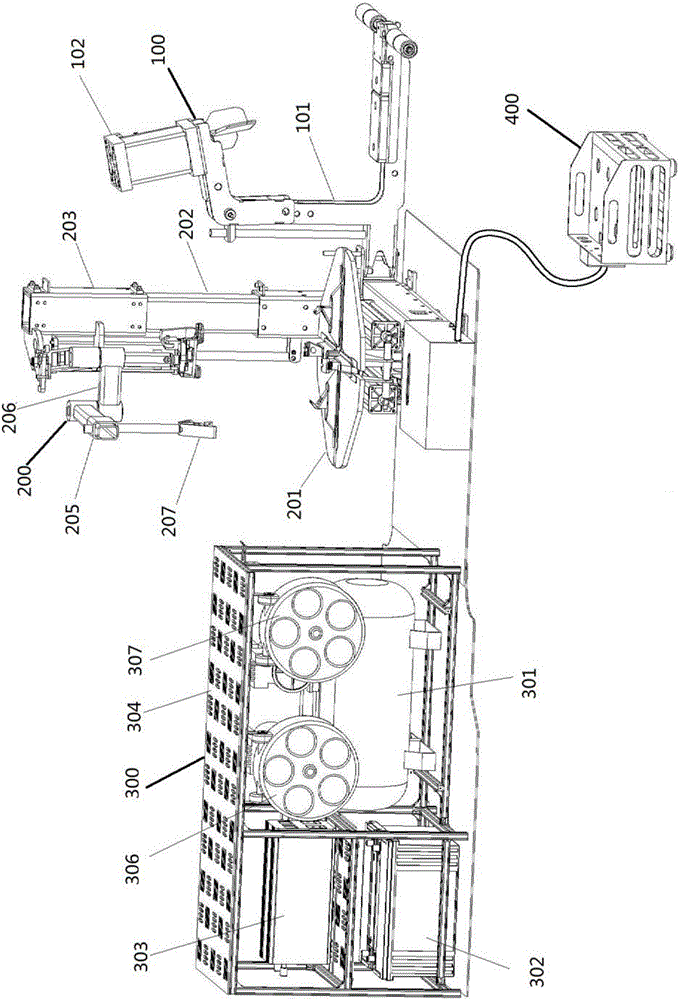

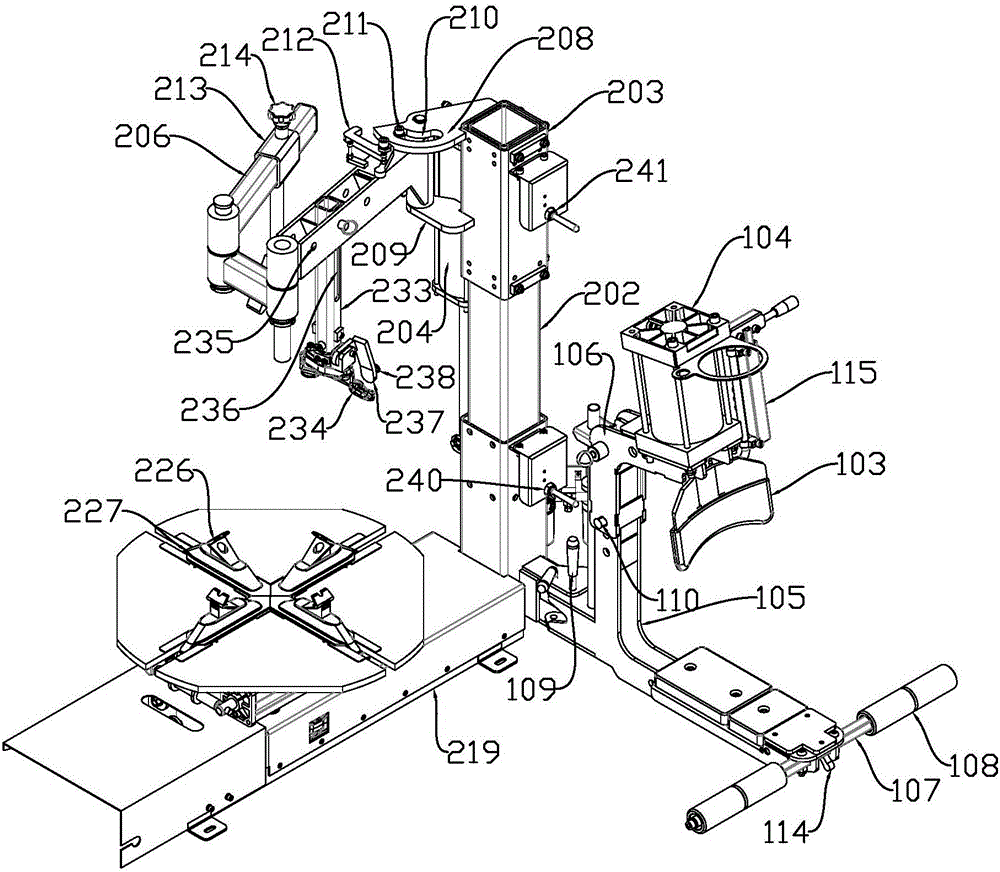

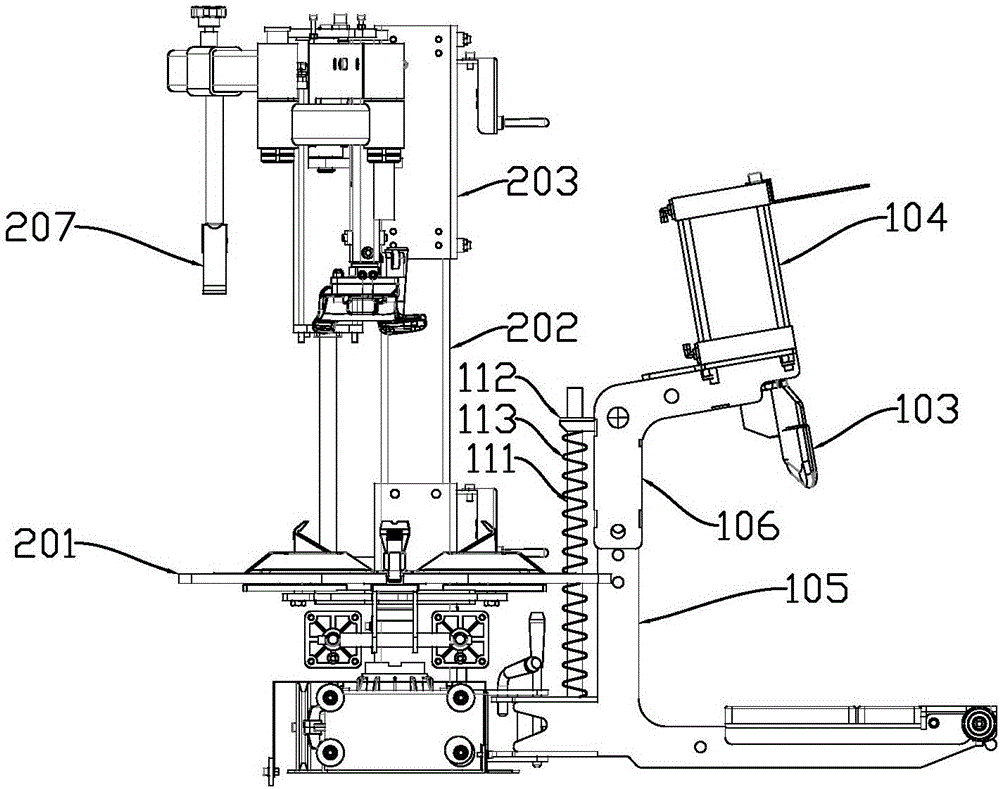

[0028] Such as Figure 1 to Figure 9 As shown, a vehicle-mounted tire changer includes a tire shoveling device 100, a tire demounting device 200 and a power unit 300 for providing power; The tire shoveling mechanism 102 on the top, the tire shoveling mechanism 102 includes a shovel body 103 and a tire shovel cylinder 104 that controls the shovel body 103; The sliding part 203 that slides on the sliding part 202, a tire beading cylinder 204 is provided between the sliding part 203 and the support column 202, and is used to control the sliding of the sliding part 203, and the beading arm 205 is provided on the sliding part 203. The bead pressing arm 205 includes at least two rotating arms 206 pivotally connected in turn, and the rotating arms 206 can swing on a plane perpendicular to the sliding direction of the slider 203. Head 207, in this embodiment, the bead bead arm 205 is pivotally connected to the slider 203, and is installed in the middle of the upper positioning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com