Railway self-dumping car chassis

A self-tipping car and underframe technology, applied in railway car body parts, underframes, transportation and packaging, etc., can solve the problems of difficult installation and disassembly, hidden safety hazards for operators, insufficient strength and rigidity, etc., to achieve convenient installation and maintenance, avoid Safety hazard, high strength and stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

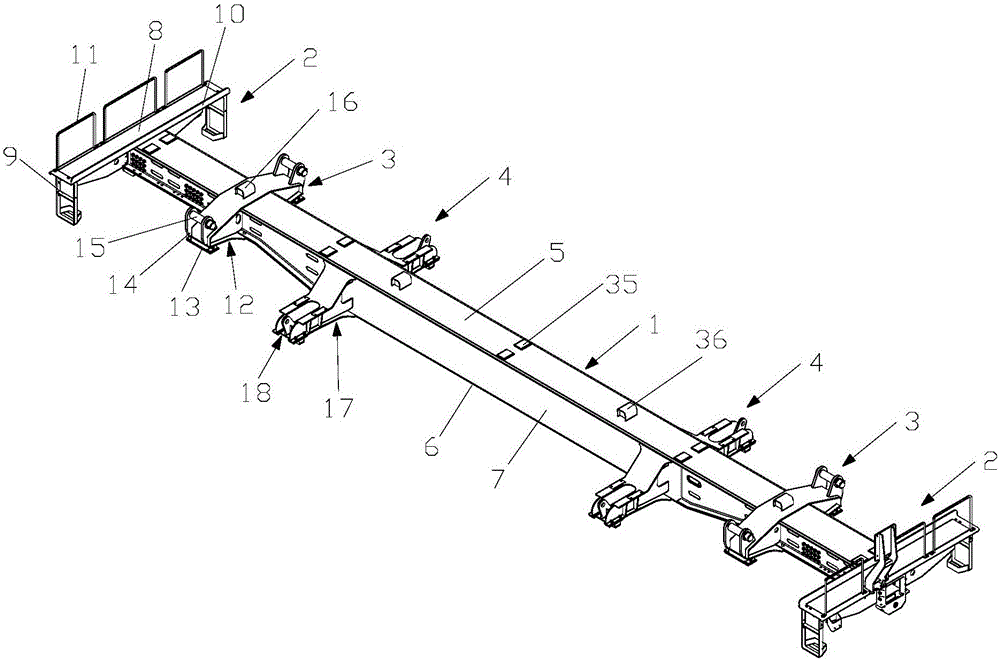

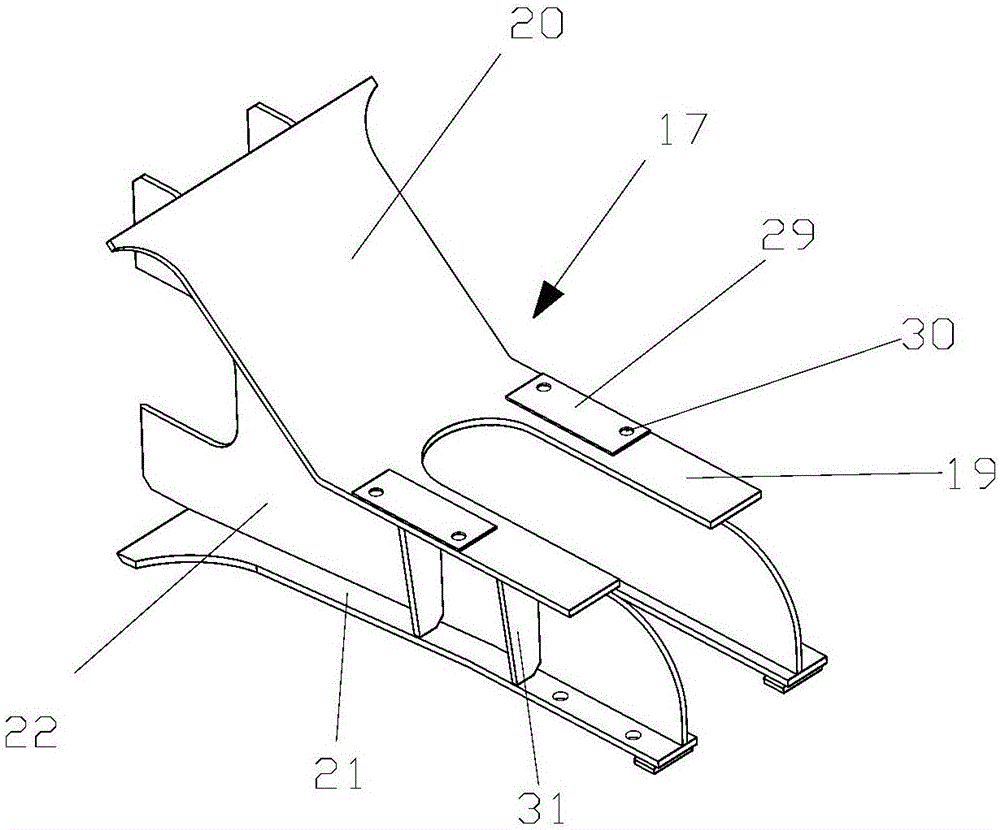

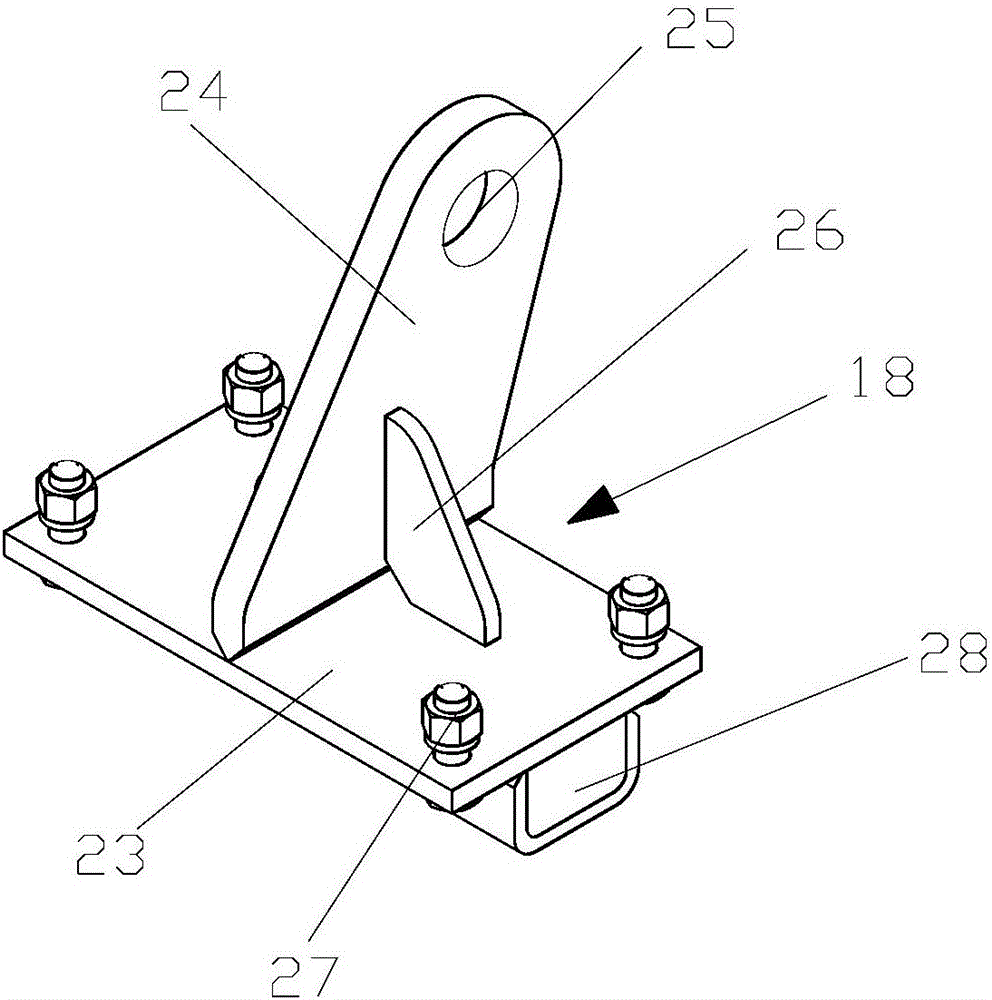

[0033] Shown in the figure is a kind of railway self-rollover underframe of the present invention, which includes a middle beam 1, two symmetrically arranged end beam mechanisms 2 fixed at both ends of the middle beam 1 and vertically fixed thereto, and two symmetrically arranged on the middle beam 1 The corbel mechanism 3, and two symmetrically arranged hydraulic cylinder support mechanisms 4 are also arranged between the two corbel mechanisms 3;

[0034] The middle sill 1 adopts a box structure or a double H-shaped structure, which consists of an upper cover 5, a lower cover 6, and two fish-belly webs 7 arranged in parallel between the upper cover 5 and the lower cover 6. Composition; on the upper cover plate 5 of the center sill 1, several adjusting wear plates 35 are arranged at intervals. The adjustment wear plate 35 can be used in conjunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com