Shipborne variable aspect fin stabilizer

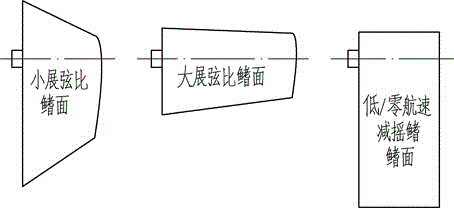

A fin stabilizer, marine technology, applied in the field of ship outfitting, can solve the problems of unfavorable anti-roll navigation economy, low lift coefficient of fin surface, etc., and achieve the effect of improving the flexibility and economy of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

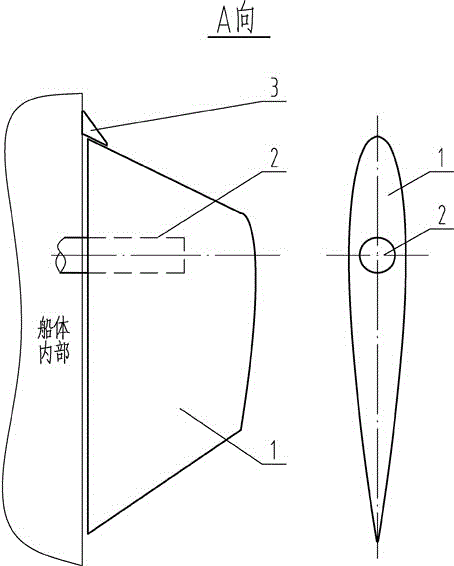

[0020] Such as figure 2 Shown is a schematic diagram of a typical fin surface structure of an existing ship stabilizer fin. Due to the internal tank capacity of military ships, non-retractable fin stabilizers are often used. In order to ensure that the size of the fin surface 1 will not exceed the width of the ship and the baseline of the ship bottom, the fin surface 1 is often designed with a small aspect ratio, and its lift coefficient is often higher. Low; in order to reduce water flow resistance, the section of the fin surface 1 mostly adopts NACA streamline airfoil; in addition, in order to prevent underwater garbage from colliding and damaging the fin shaft 2, a protective baffle 3 is often arranged at the front of the fin surface 1.

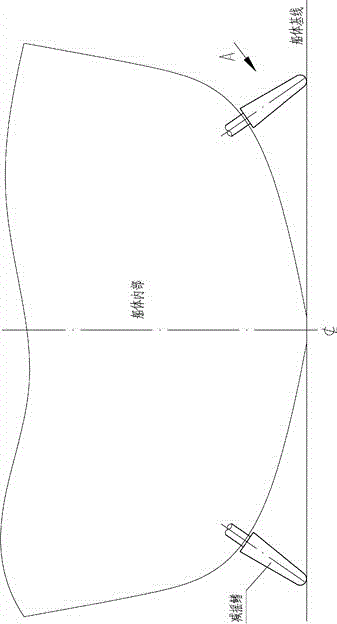

[0021] Such as Figure 4 Shown is the structural representation of the present invention. The fin shaft 2 is slidingly connected with the fixed shaft bracket on the hull, the fin surface 1 and the fin shaft 2 are connected through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com