Aluminum alloy paddle and manufacturing technique thereof

A technology of aluminum alloy and aluminum alloy materials, which is applied in the field of boat oars, can solve the problems of large footprint, oar sinking, and inconvenient storage of oars, and achieve the effect of preventing sinking and increasing buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

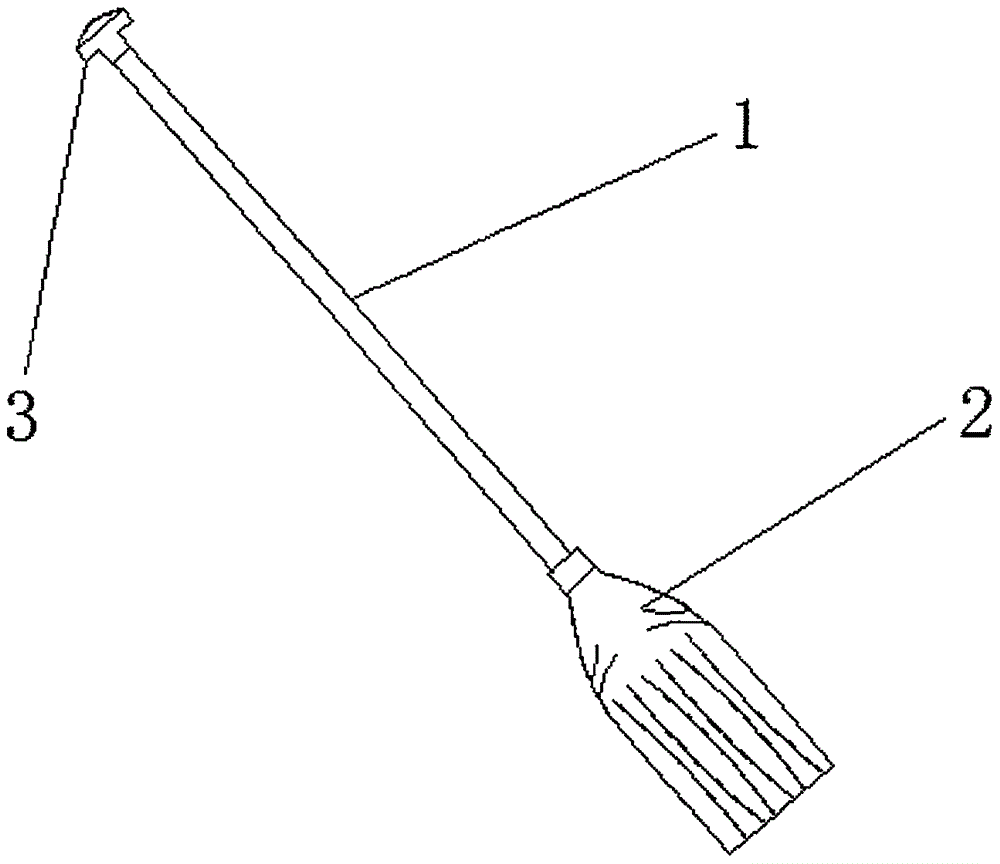

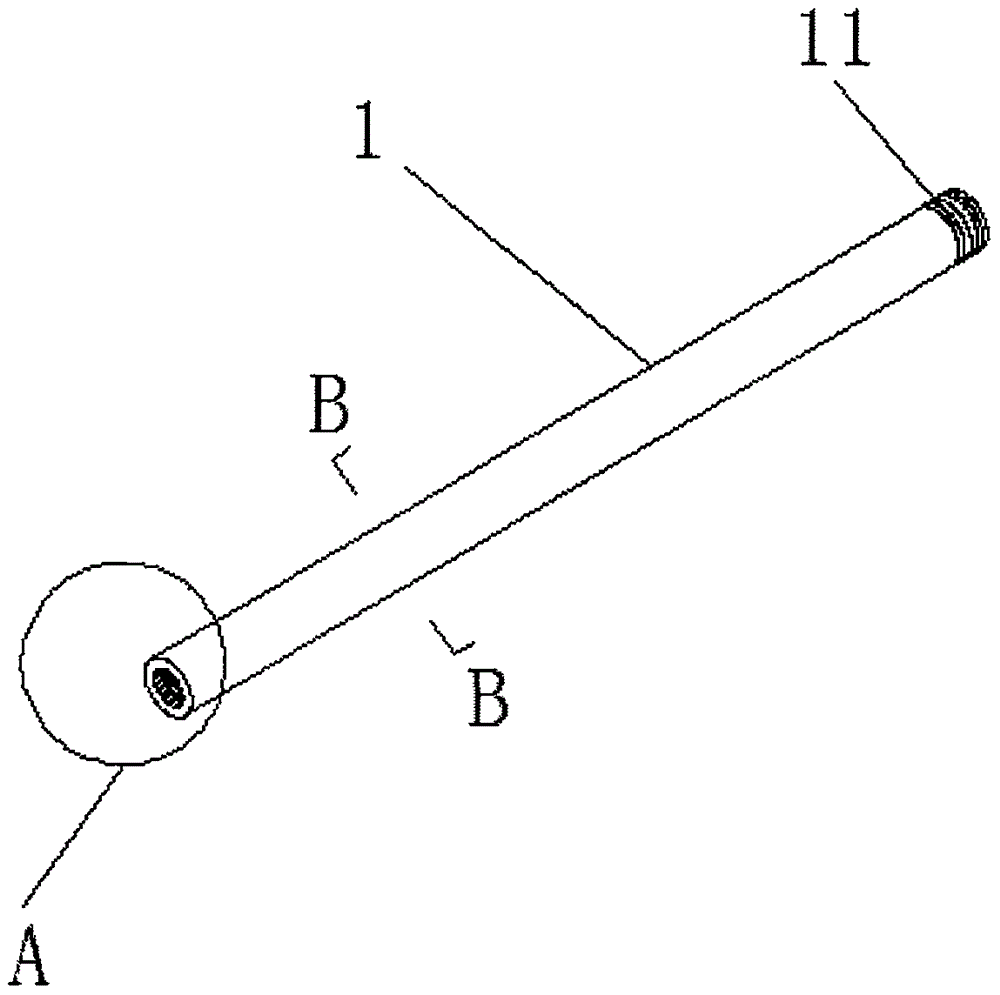

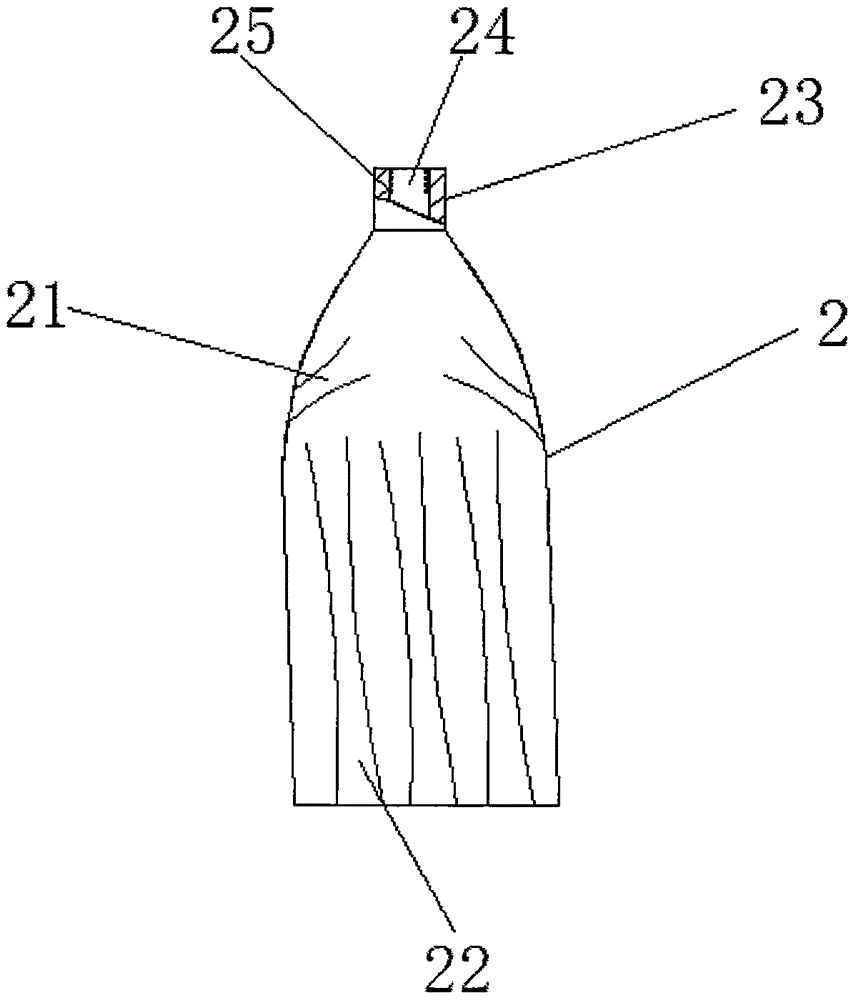

[0032] An aluminum alloy boat paddle, comprising a paddle rod 1, a handle 3, and a paddle board 2. One end of the paddle rod 1 is provided with a paddle rod external thread 11, and the other end of the paddle rod 1 is provided with a paddle rod internal thread 12. One end of the handle 3 is provided with a handle external thread 31, the handle 3 is threadedly connected to the paddle shaft internal thread 12 through the handle external thread 31, the front of the paddle plate 2 is provided with an oblique diversion groove 21 and a long diversion groove 22. The top of the paddle board 2 is provided with a mounting protruding rod 23, the mounting protruding rod 23 is provided with a mounting hole 24, and the inner wall of the mounting hole 24 is provided with a mounting hole internal thread 25, and the paddle rod 1 contains a paddle rod external thread 11 One end is threadedly connected to the internal thread 25 of the mounting hole.

[0033] The paddle rod 1 has a tubular structure...

Embodiment 2

[0050] An aluminum alloy boat paddle, comprising a paddle rod 1, a handle 3, and a paddle board 2. One end of the paddle rod 1 is provided with a paddle rod external thread 11, and the other end of the paddle rod 1 is provided with a paddle rod internal thread 12. One end of the handle 3 is provided with a handle external thread 31, the handle 3 is threadedly connected to the paddle shaft internal thread 12 through the handle external thread 31, the front of the paddle plate 2 is provided with an oblique diversion groove 21 and a long diversion groove 22. The top of the paddle board 2 is provided with a mounting protruding rod 23, the mounting protruding rod 23 is provided with a mounting hole 24, and the inner wall of the mounting hole 24 is provided with a mounting hole internal thread 25, and the paddle rod 1 contains a paddle rod external thread 11 One end is threadedly connected to the internal thread 25 of the mounting hole.

[0051] The paddle rod 1 has a tubular structure...

Embodiment 3

[0068] An aluminum alloy boat oar, comprising a paddle rod 1, a handle 3 and a paddle board 2. One end of the paddle rod 1 is provided with a paddle rod external thread 11, and the other end of the paddle rod 1 is provided with a paddle rod internal thread 12. One end of the handle 3 is provided with a handle external thread 31, the handle 3 is threadedly connected to the paddle shaft internal thread 12 through the handle external thread 31, and the front of the paddle plate 2 is provided with an inclined diversion groove 21 and a long diversion groove 22. The top of the paddle board 2 is provided with a mounting protruding rod 23, the mounting protruding rod 23 is provided with a mounting hole 24, and the inner wall of the mounting hole 24 is provided with a mounting hole internal thread 25, and the paddle rod 1 contains a paddle rod external thread 11 One end is threadedly connected to the internal thread 25 of the mounting hole.

[0069] The paddle rod 1 has a tubular structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com