Continuous material dividing device

A material distribution device and hopper technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of high energy consumption, energy waste, and large energy consumption, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

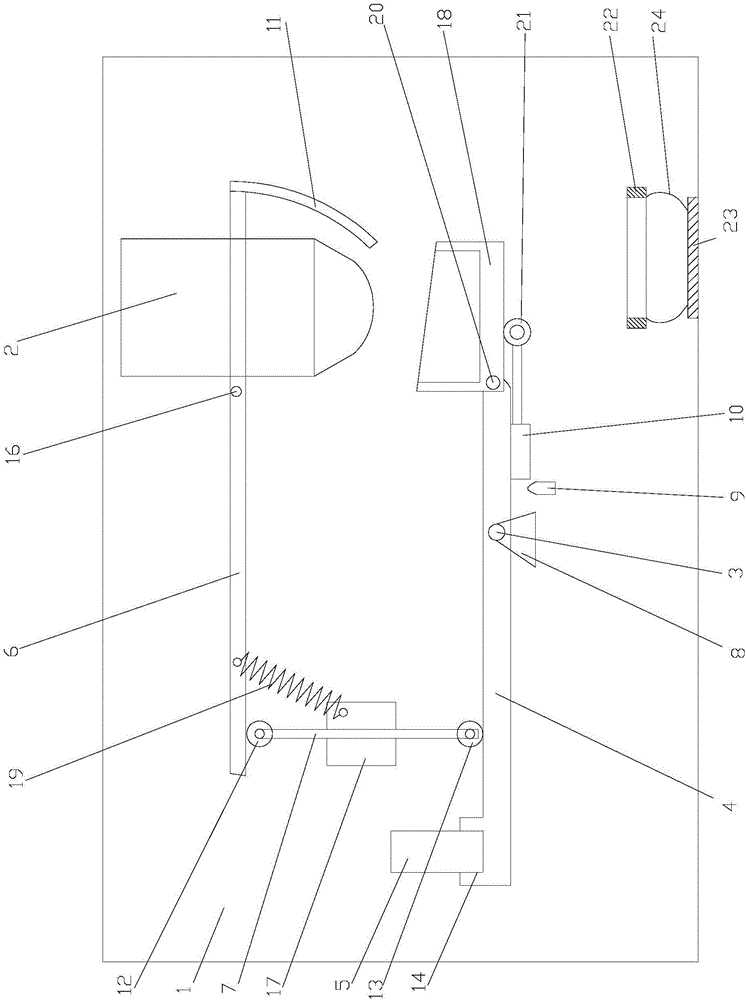

[0018] The continuous material distributing device of the present invention comprises a frame 1, which is provided with a barrel 2 for placing materials, and the frame 1 is connected with a swing rod 4 through the first hinge point 3, and a counterweight is provided at one end of the swing rod 4 5. The other end is rotatably connected with a hopper 18. The hopper 18 is located below the barrel 2. The swing rod 4 is provided with a cylinder 10 for driving the hopper 18 to rotate; One end of the block 5 is the transmission area, that is, the left end of the fork 4 in the figure; the one end near the hopper 18 is the blanking area, that is, the right end of the fork 4 in the figure; Located above the swing bar 4, the end of the cross bar 6 close to the barrel 2 is provided with an arc-shaped baffle 11 for controlling the opening and closing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com