An electric wire bird-nesting preventing mechanism based on a pressure bar structure

A technology of electric wires and pressure rods, which is applied in the field of wire anti-bird nesting mechanism, can solve the problems of high risk factor and difficulty of manual removal, and achieve the effects of reliable structure, preventing birds from nesting, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

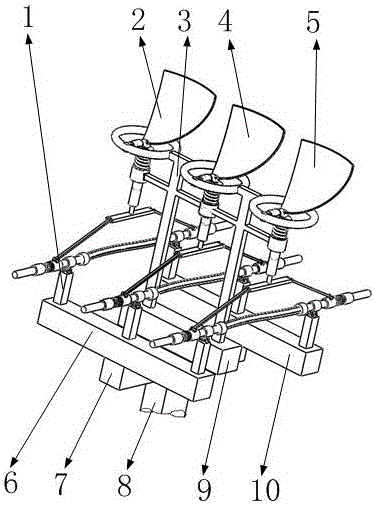

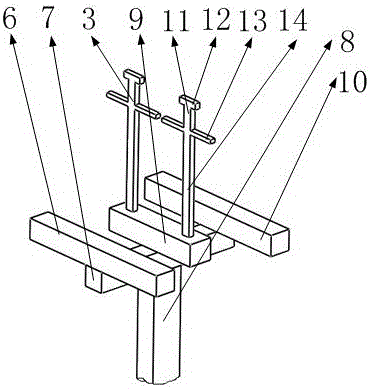

[0028] Such as figure 1 , 3 , 4, it includes a energized line support 1, a first energized line 2, a second energized line 4, a third energized line 5, a first support beam 6, a beam 7, a pillar 8, a second support beam 9, a third Support beam 10, first support frame 3, second support frame 11, electric wire 15, wherein crossbeam 7 is installed on pillar 8 upper end, the top of crossbeam 7 is installed with it vertical first support beam 6, Second support beam 9 and the 3rd support beam 10, the effect of crossbeam 7 is to support the first support beam 6, the second support beam 9 and the 3rd support beam 10, each has three on the first support beam 6 and the 3rd support beam 10. A energized line support 1 installed equidistantly, and the first energized line 2, the second energized line 4 and the first energized line 2, the second energized line 4, and the top of the corresponding 3 groups of energized line supports 1 between the first support beam 6 and the third support be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com