Labeling Machine

A labeling machine and labeling technology, applied in the direction of labeling machines, labels, packaging, etc., can solve the problems of small position deviation, high-precision labeling, inability to protect the suction head, etc., and achieve rapid installation and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present application, not as a limitation to the present application, and, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other .

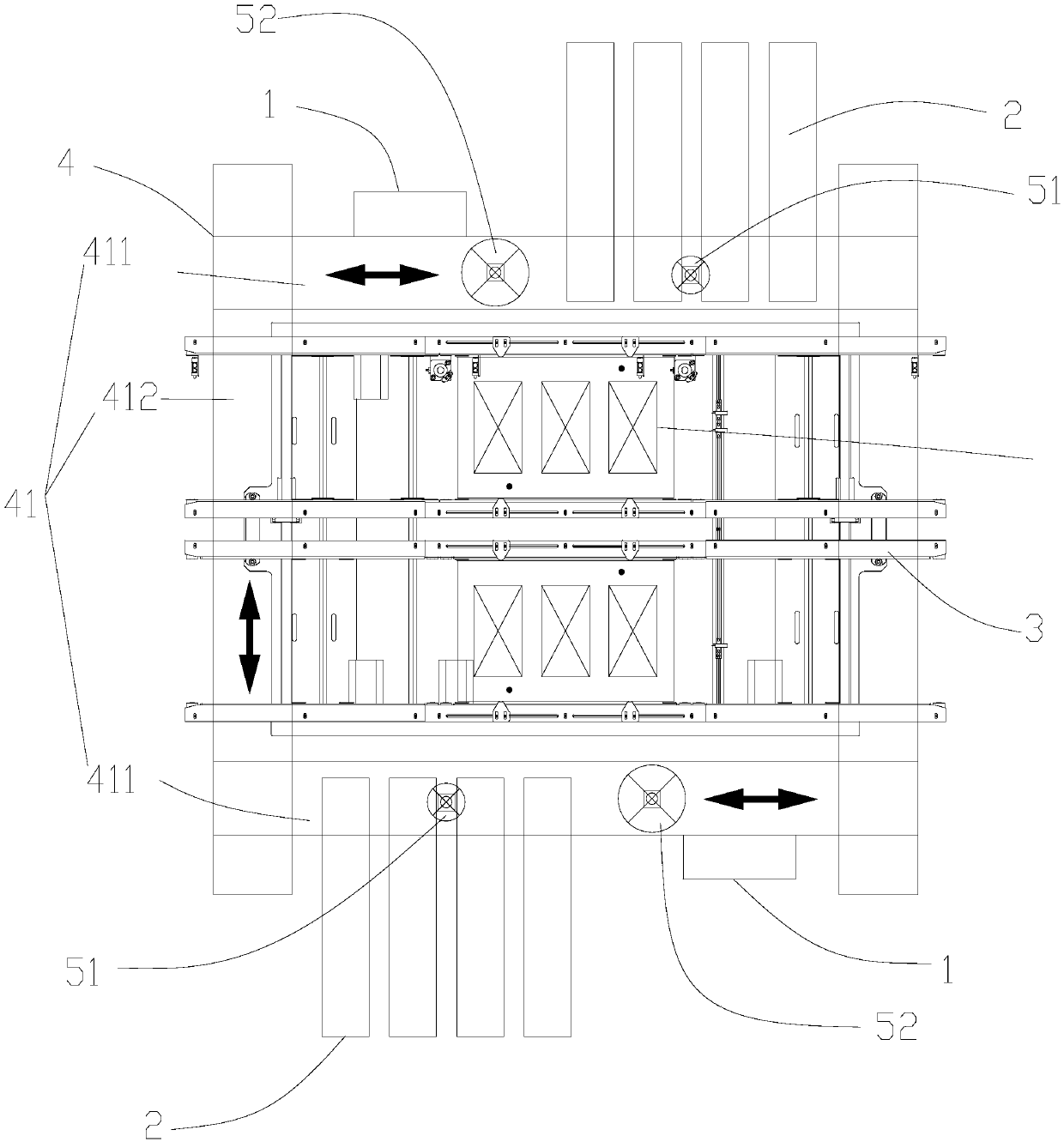

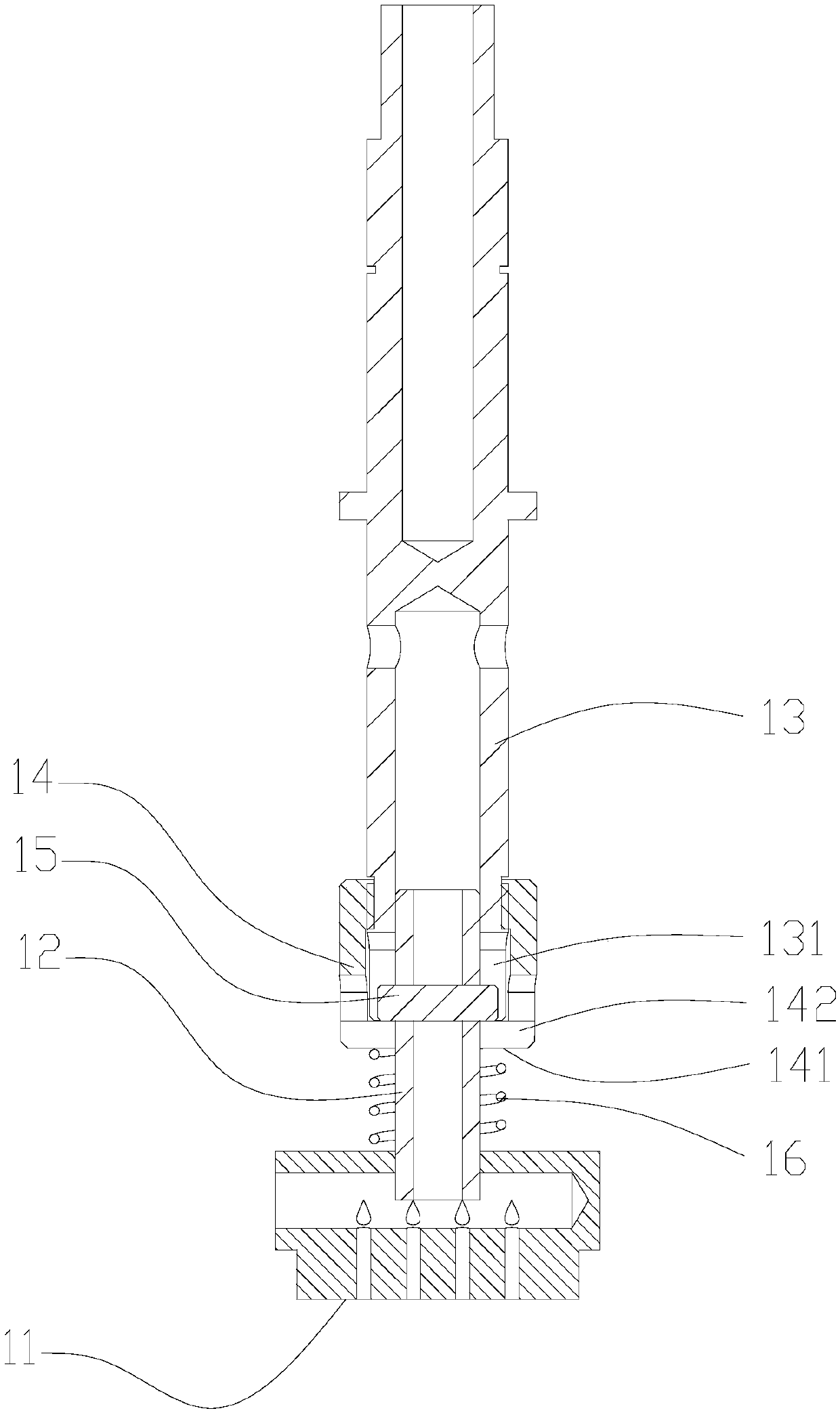

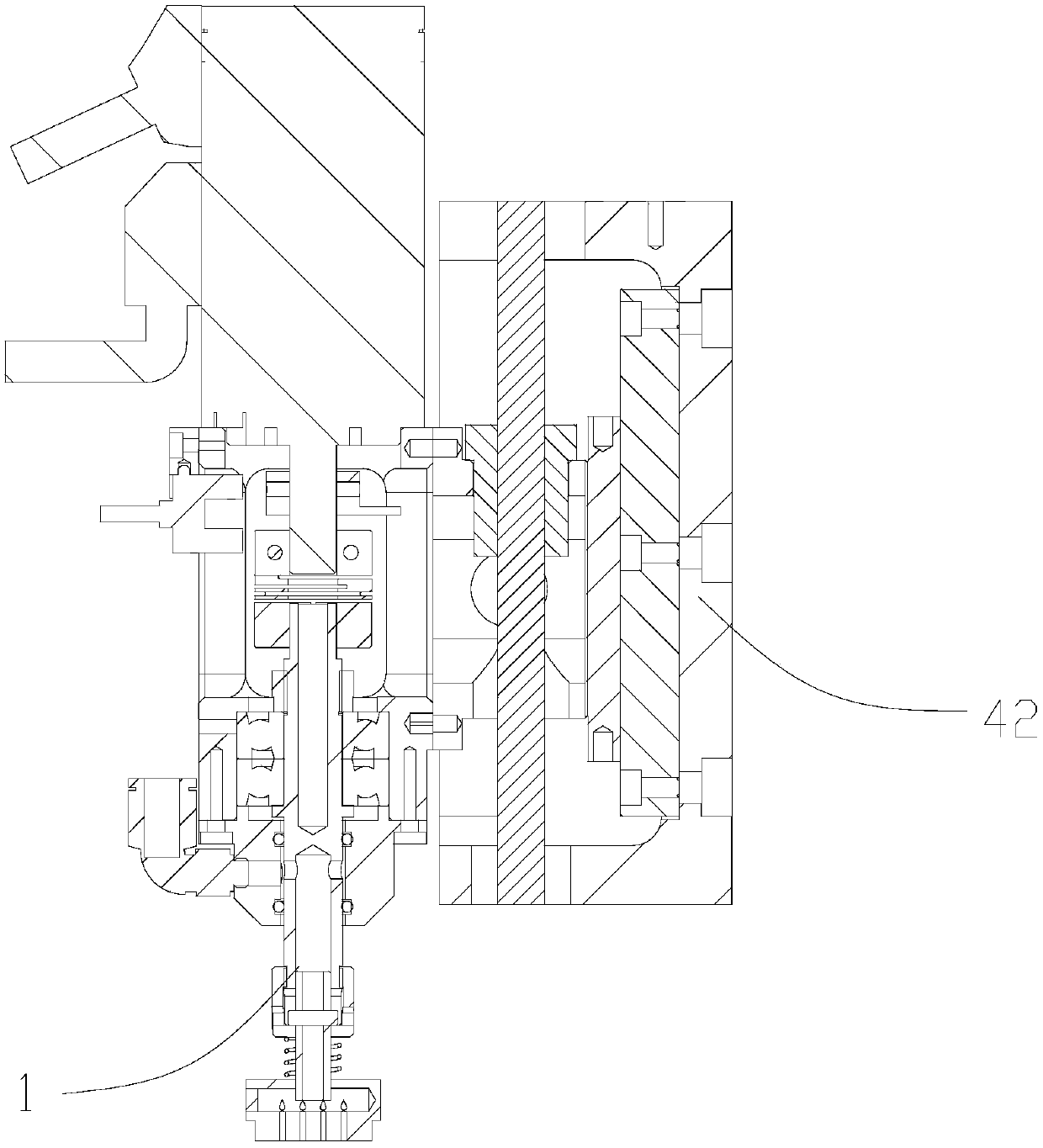

[0020] Such as Figure 1~Figure 3 As shown, the embodiment of the present invention provides a labeling machine, including a placement head 1, a label feeder 2 for supplying labels, a conveying device 3 for transporting workpieces to be labeled, and for driving the The placement head 1 is a three-dimensional motion platform 4 that moves three-dimensionally between the label feeder 2 and the conveying device 3, and the labeling machine also includes a relatively fixed connection with the placement head 1 for alig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap