A refrigerator vertical box transfer machine

A technology of transfer machine and vertical box, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of inability to guarantee product quality, low work efficiency, and many potential safety hazards, and achieve stable and reliable inversion process and structure. Simple, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

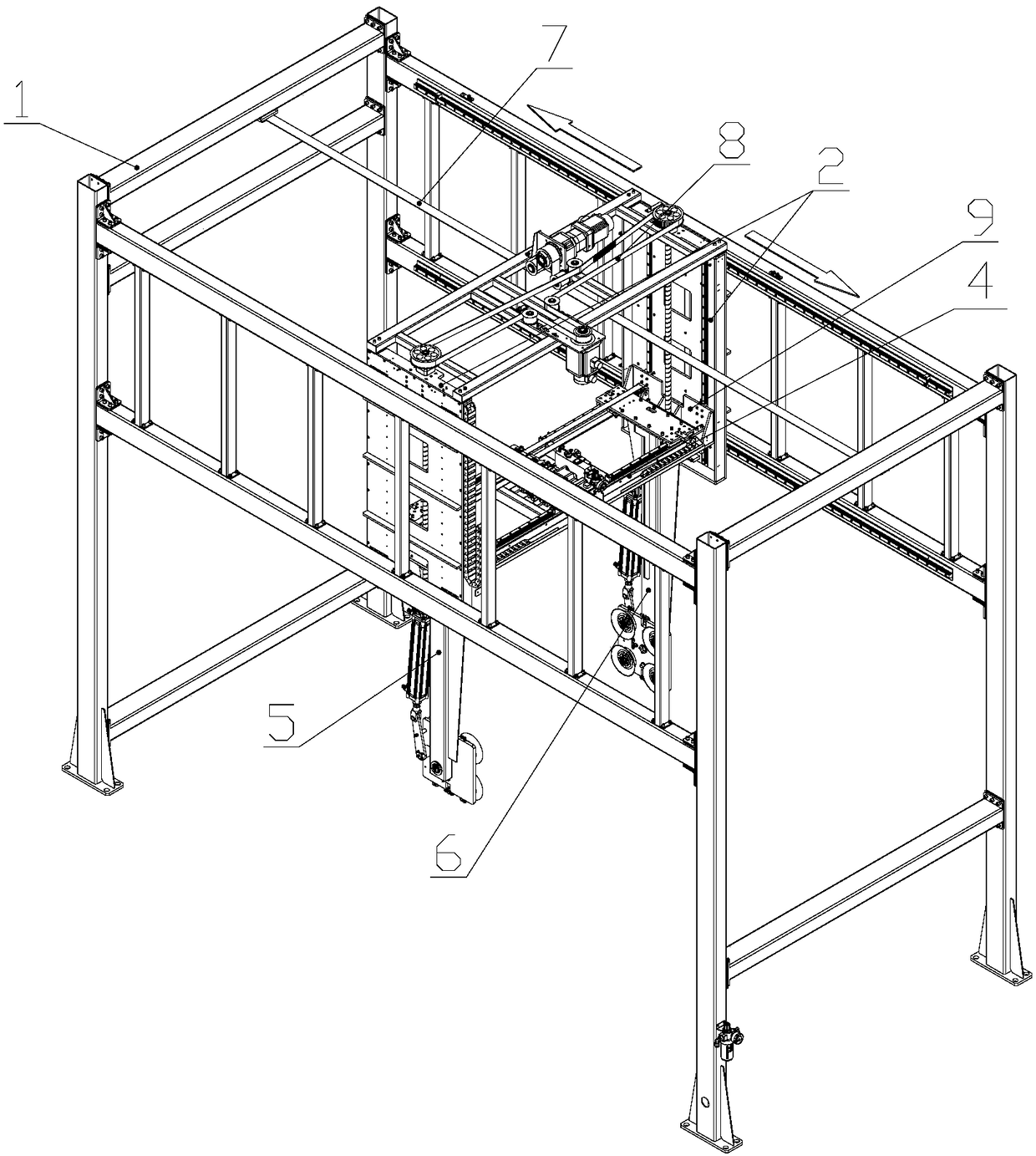

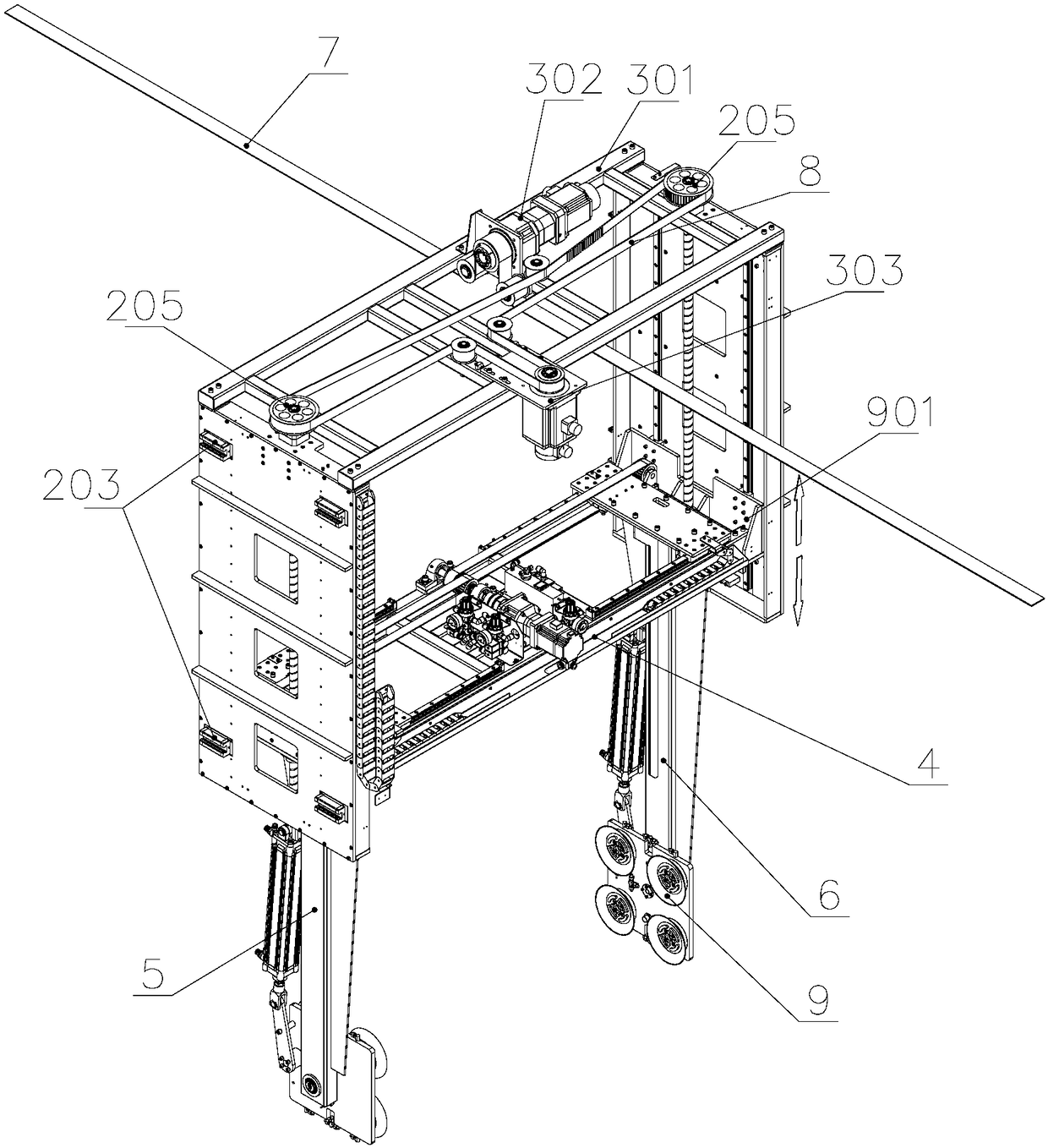

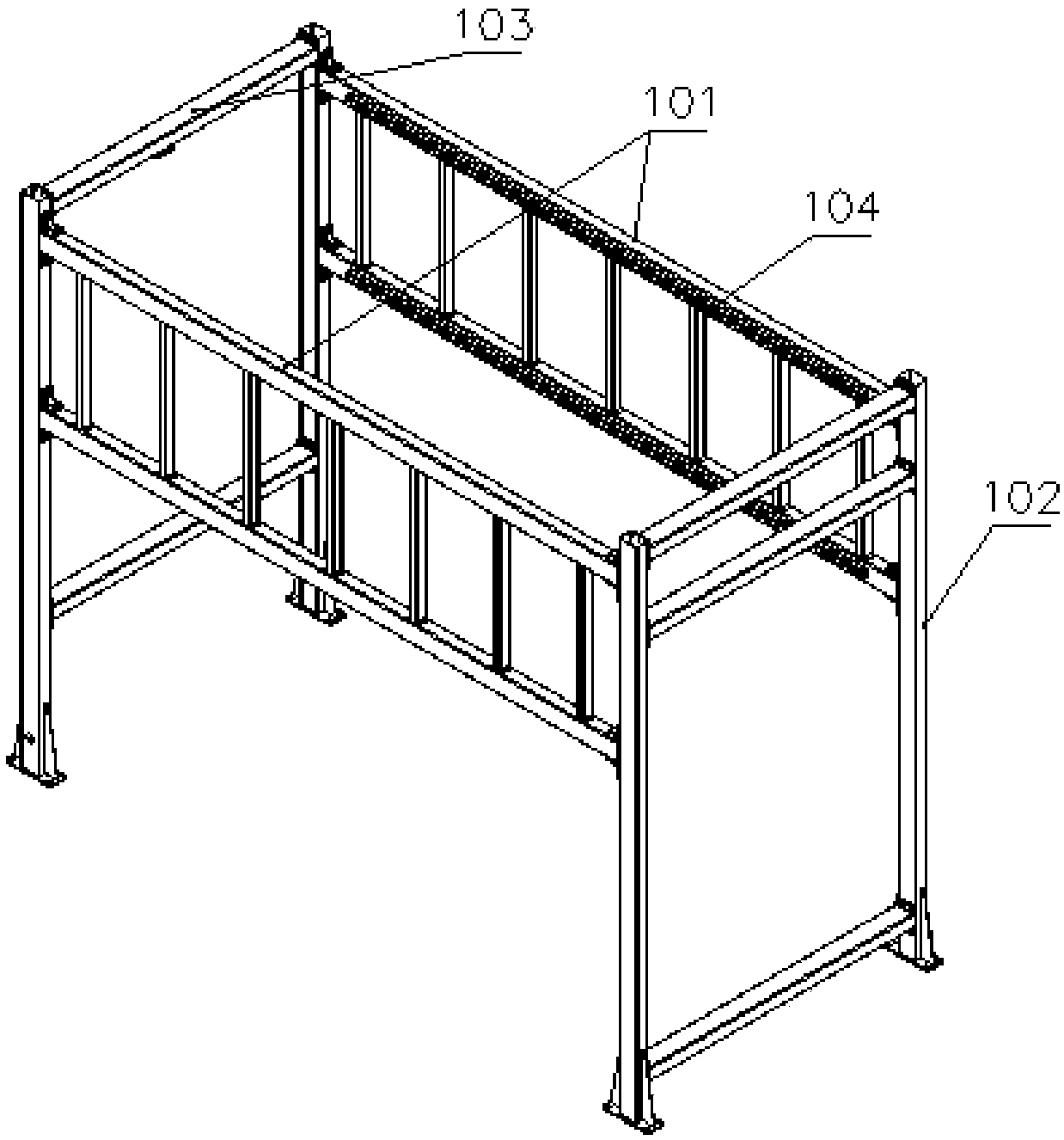

[0029] Such as Figure 1 to Figure 7 Shown, the present invention comprises frame 1, and frame 1 is provided with the horizontal movement dolly 2 that moves along horizontal direction, and horizontal movement dolly 2 is provided with lift trolley 9, and lift trolley 9 is along the vertical direction relative to horizontal movement trolley 2. To move, one side of the lifting trolley 9 is equipped with a clamping and turning mechanism A5, and the other side is equipped with a matching clamping and turning mechanism B6, and the transmission output ends of the clamping and turning mechanism A5 and the clamping and turning mechanism B6 are all provided with The suction cup, the clamping turning mechanism A5 and the clamping turning mechanism B6 all adopt the mode of crank connecting rod transmission to drive the sucking cup to rotate by 90°.

[0030] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com