Cloth cutting device provided with shell and used for textile manufacturing machine and cloth cutting method of cloth cutting device

A technology of textile machinery and cloth cutting, which is applied in the cutting of textile materials, textiles and papermaking, etc., which can solve the problems of reducing the efficiency of cloth covering, wrinkling of cloth, high quality of cloth covering and blade quality, etc. Destroy and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

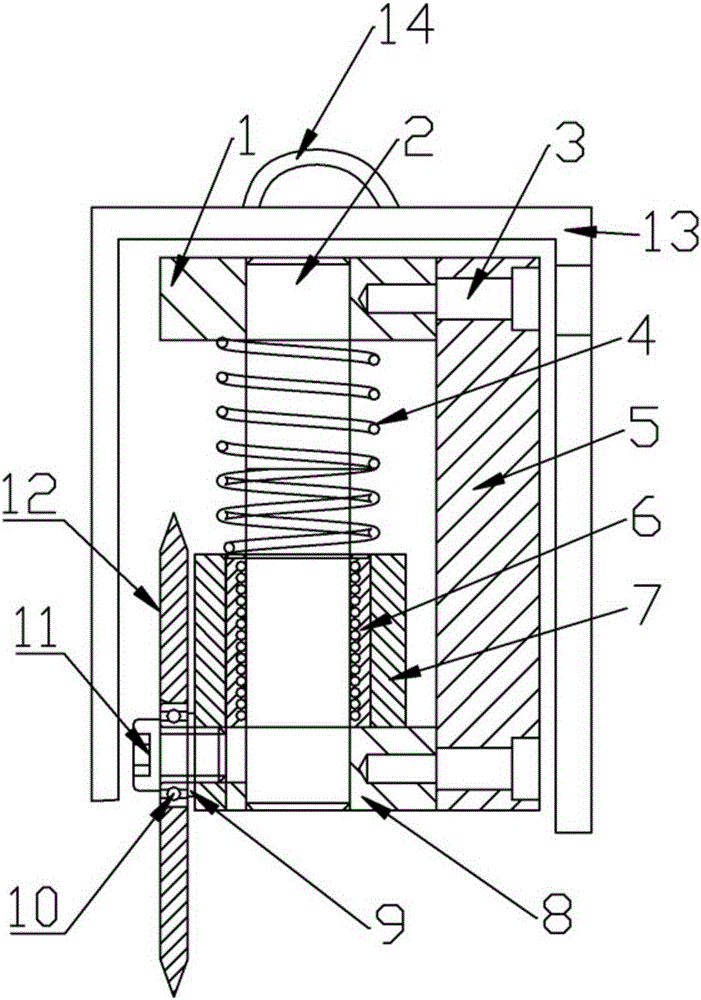

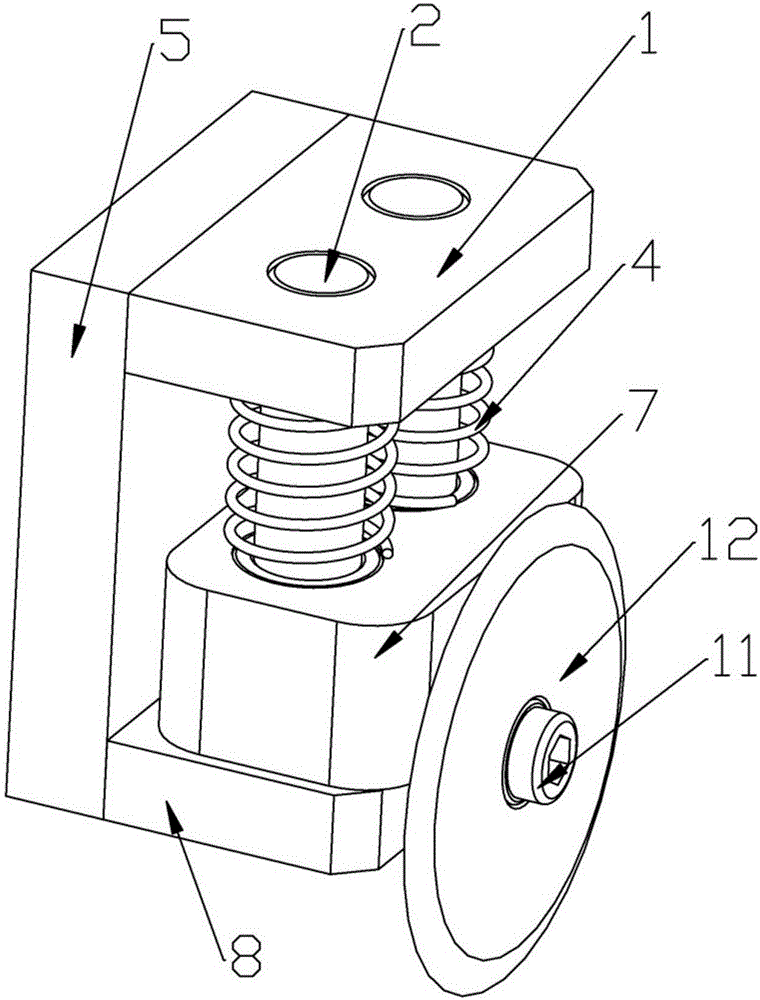

[0024] see figure 1 , a fabric cutter with a housing for a textile machine, comprising an upper support plate, a guide shaft, a back plate, a slider, a lower support plate and a hob blade, the upper support plate and the lower support plate are fixedly connected to the upper and lower sides of the back plate respectively In the lower part, the guide shaft connects the upper support plate and the lower support plate, and the slider is slidably set on the guide shaft;

[0025] There are mounting bolts on the slider, and the rolling blade is rotatably set on the mounting bolt, and the lower end of the rolling blade is lower than the lower end surface of the lower support plate;

[0026] Also includes a spring, the spring is set on the guide shaft, one end of the spring is in contact with the slider, and the other end is in contact with the upper support plate;

[0027] It also has a shell with an open bottom, and the upper support plate, guide shaft, back plate, slider, and lowe...

Embodiment 2

[0033] A cloth cutting method of the above-mentioned textile machine with a cloth cutter with a housing, comprising the following steps:

[0034] 1) When starting to cut the cloth, the hob blade is in contact with the cloth, and the hob blade is pressed to move the hob blade upward, and the spring is compressed so that the spring forms a pressing force that presses the hob blade;

[0035] 2) The cloth cutter starts to walk along the cutting line, and the roller blade rolls on the cutting line to complete the cloth cutting action.

[0036] The back plate can be connected with the machine tool, and the cloth cutter moves under the drive of the machine tool.

[0037] When the hob blade encounters an obstacle or passes through an obstacle, the hob blade moves upwards accordingly, compressing the spring, and after the hob blade passes through the obstacle, under the pressure of the spring, the hob blade returns to its position and continues to complete the cutting action.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com