Sediment removal and grouting device and sediment removal and grouting method adopting device

A grouting device and slag cleaning technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of poor cleaning effect of slag at the bottom of cast-in-place piles, poor bearing capacity of cast-in-place piles, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

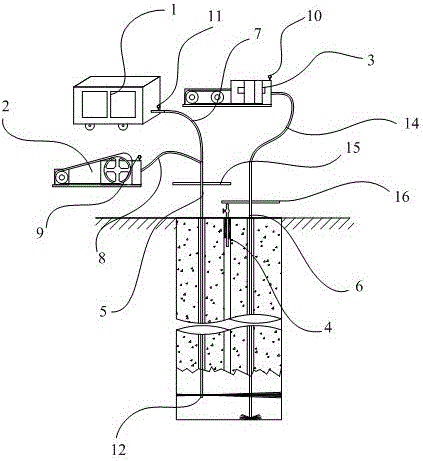

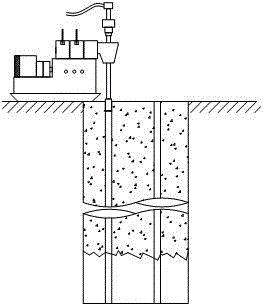

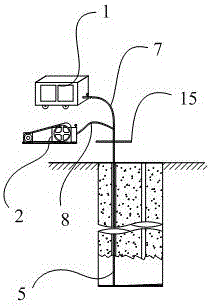

[0035] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The present invention proposes an embodiment of a slag removal and grouting device. Refer to figure 1 As shown, it includes an air compressor 1 and / or a high-pressure pump 2, a low-pressure speed-regulating pump 3 and a short grouting pipe 4. The short grouting pipe 4 is provided with a valve 41 that can be opened and closed. The air compressor 1 And / or the high-pressure pump 2 is connected with a high-pressure grouting pipe 5 that can go deep into the bottom of the coring hole, and the low-pressure speed-regulating pump 3 is connected with a low-pressure grouting pipe 6 that can go deep into the bottom of the coring hole.

[0036] The slag removal and grouting device in this embodiment can cooperate with the air compressor 1 and the high-pressure pump 2 during the slag removal, and be connected with the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com