Wind power and bridge rock-socketed construction process

A construction technology and bridge technology, which is applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of increased difficulty in hoisting and driving of perforated pile foundations on the seabed and mud surface, and the inability of tooling to adapt to operating requirements. Achieve the effects of robust and reliable construction process, high drilling efficiency and wide operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

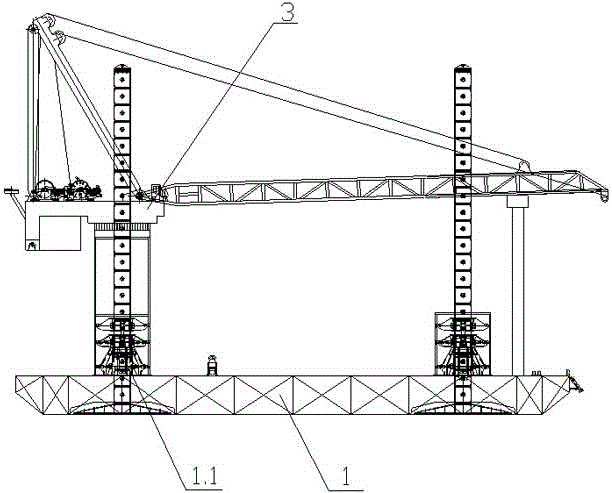

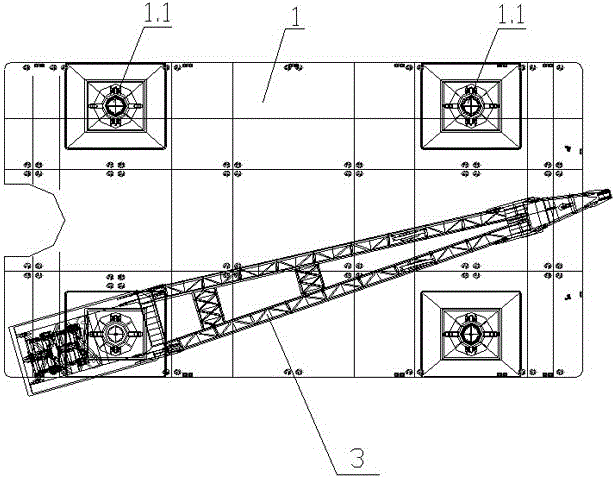

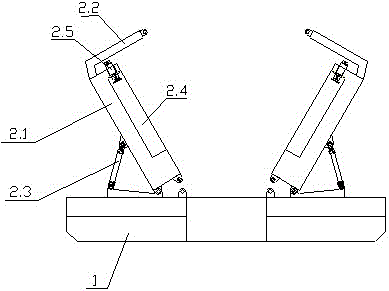

[0039] see Figure 1~10 , a kind of wind power and bridge rock-socketed construction technology that the present invention relates to, described technology comprises the following steps:

[0040] Step 1. The self-elevating construction platform sails above the construction location and locates at the construction location;

[0041] Step 2. The lifting pile legs on the four corners of the self-elevating construction platform are lowered to the mud surface of the seabed to lift the self-elevating construction platform above the sea surface;

[0042] Step 3: Install the steel casing. The crane on the self-elevating construction platform lifts the steel casing and then under the guidance of the pile holder, it is driven vertically downwards into the mud surface of the seabed with a vibrating hammer (if it can be made The steel casing is drilled into silty clay, muddy silty fine sand, and medium-coarse sand until the granite layer stops),

[0043] Step 4, the jack-up construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com