Offshore rock-socketed operation platform

A work platform, self-elevating technology, applied in artificial islands, lifting devices, infrastructure engineering and other directions, can solve the problems of increased difficulty in hoisting and driving of perforated pile foundations, inability to adapt to operating requirements, etc., and achieve the construction process. Robust and reliable, high drilling efficiency, wide operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

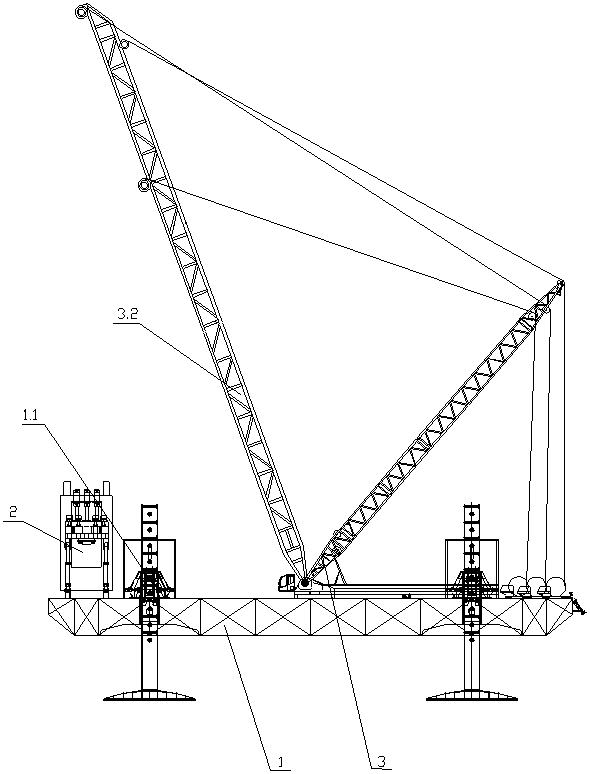

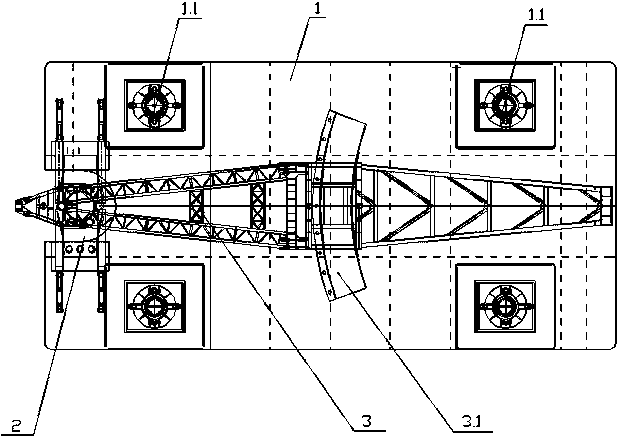

[0032] see Figure 1~6 , an offshore rock-socketed operation platform related to the present invention, the offshore rock-socketed operation platform includes a self-elevating operation platform 1, and four lifting legs 1.1 are installed on the four corners of the self-elevating operation platform 1 ,

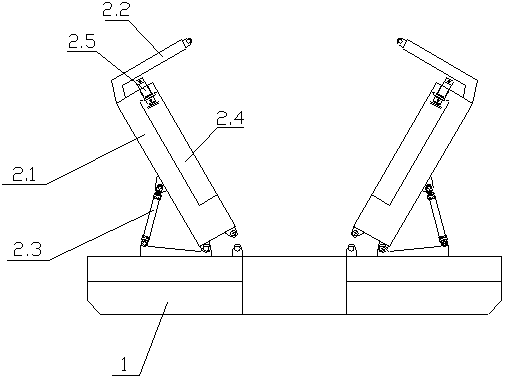

[0033] A drilling device 2 is installed on the deck of the self-elevating work platform 1, and the drilling device 2 includes a group of door frames with an openable structure, and the door frames include two symmetrically arranged turning parts 2.1. One end of the bottom of the turning part 2.1 is hinged to the deck of the self-elevating work platform 1, and the tops of the two turning parts 2.1 are horizontally connected with an upper connecting plate 2.2, and the two upper connecting plates 2.2 are connected through pins and other plug-in parts. The design realizes the opening and closing control, and each turning member 2.1 is provided with a turning oil cylinder 2.3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com