Method for gas extraction on weak surrounding rock fully mechanized caving face

A fully mechanized caving face and gas drainage technology, which is applied in the direction of gas discharge, mining fluid, mining equipment, etc., can solve the problems that threaten the safety of workers and equipment, oblique drilling is difficult to form holes, and gas drainage effect is poor , to achieve the effects of preventing gas from exceeding the limit, wide application, and reducing the gas concentration in the upper corner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

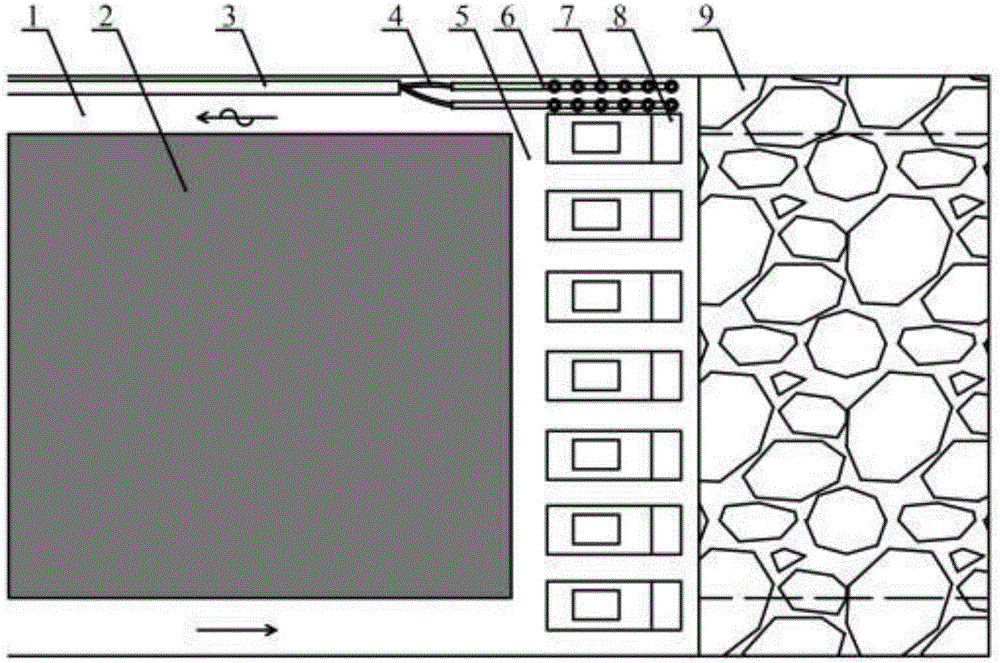

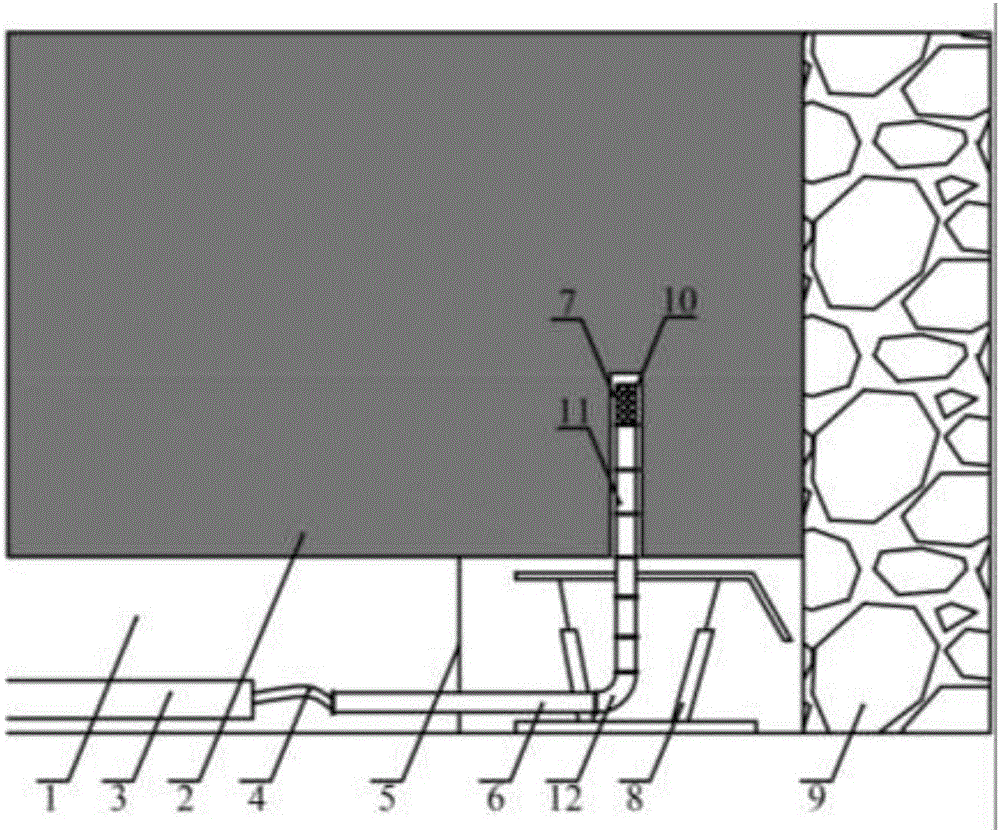

[0022] The gas drainage method of the fully mechanized caving working face of the soft surrounding rock of the present invention uses a pneumatic bolter to construct a riser to the upper part of the coal seam at the upper corner of the return air roadway of the fully mechanized caving face, and arranges the gas drainage riser in the coal seam , timely drain the large amount of gas generated during the top-coal caving operation, and reduce the gas concentration in the fully mechanized mining face. The specific steps are as follows:

[0023] a. Mining the 3m coal seam at the lower part of the 5th thick coal seam of the fully mechanized caving face, and completing the moving of the fully mechanized caving hydraulic support 8, and preparing for the top coal caving operation;

[0024] b. Between the wall of the return air roadway at the corner of the working fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com