#-shaped universal bracket of ocean power generation device

A power generation device, a well-shaped technology, applied in the field of steel structure devices and offshore platform steel structure devices, can solve problems such as difficulty in resisting fatigue strength damage, structural fatigue strength damage, strength damage, etc., achieve good fatigue resistance performance, improve Local structural strength, the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

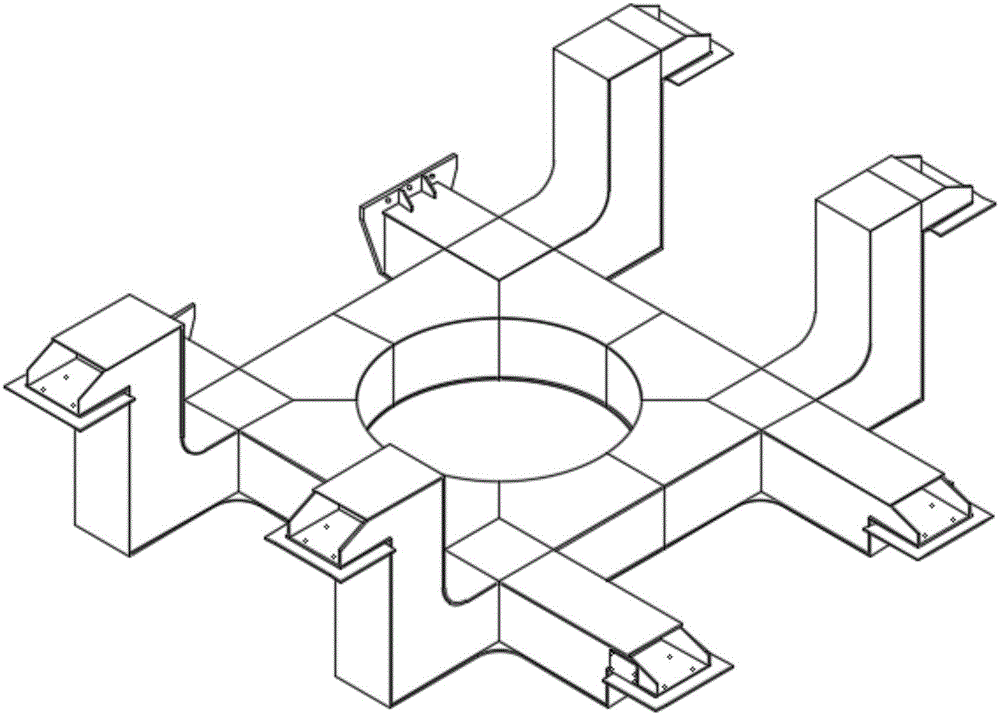

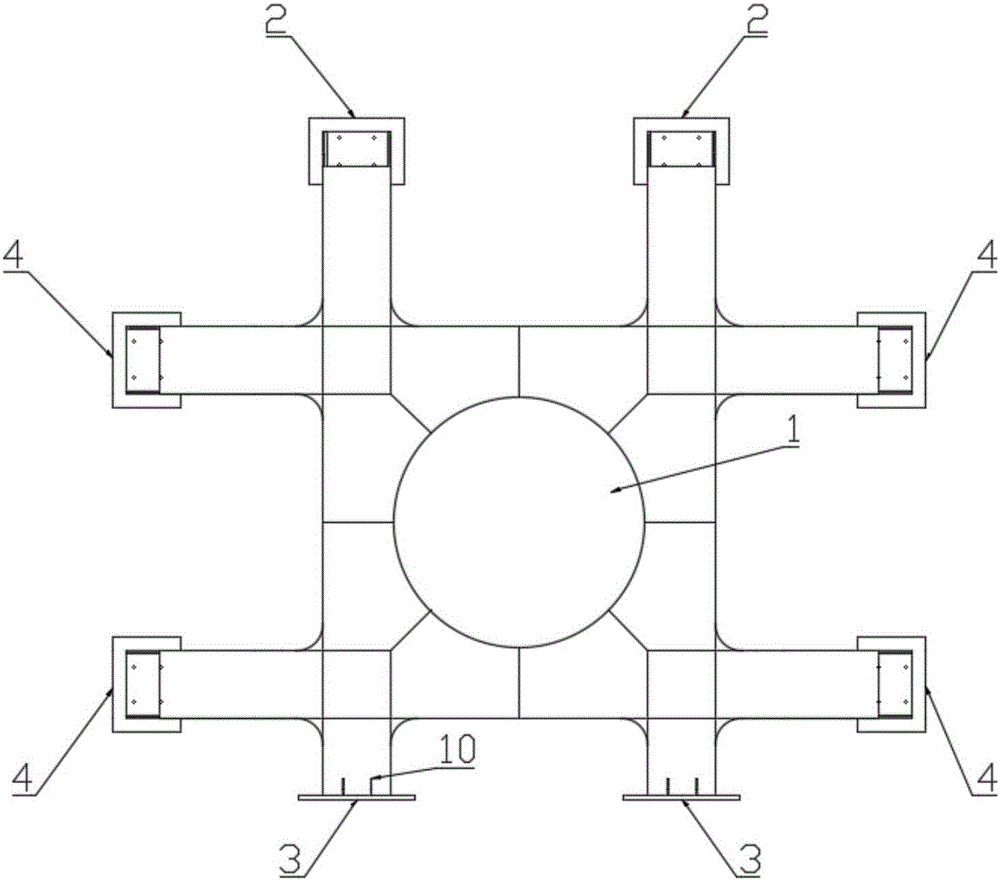

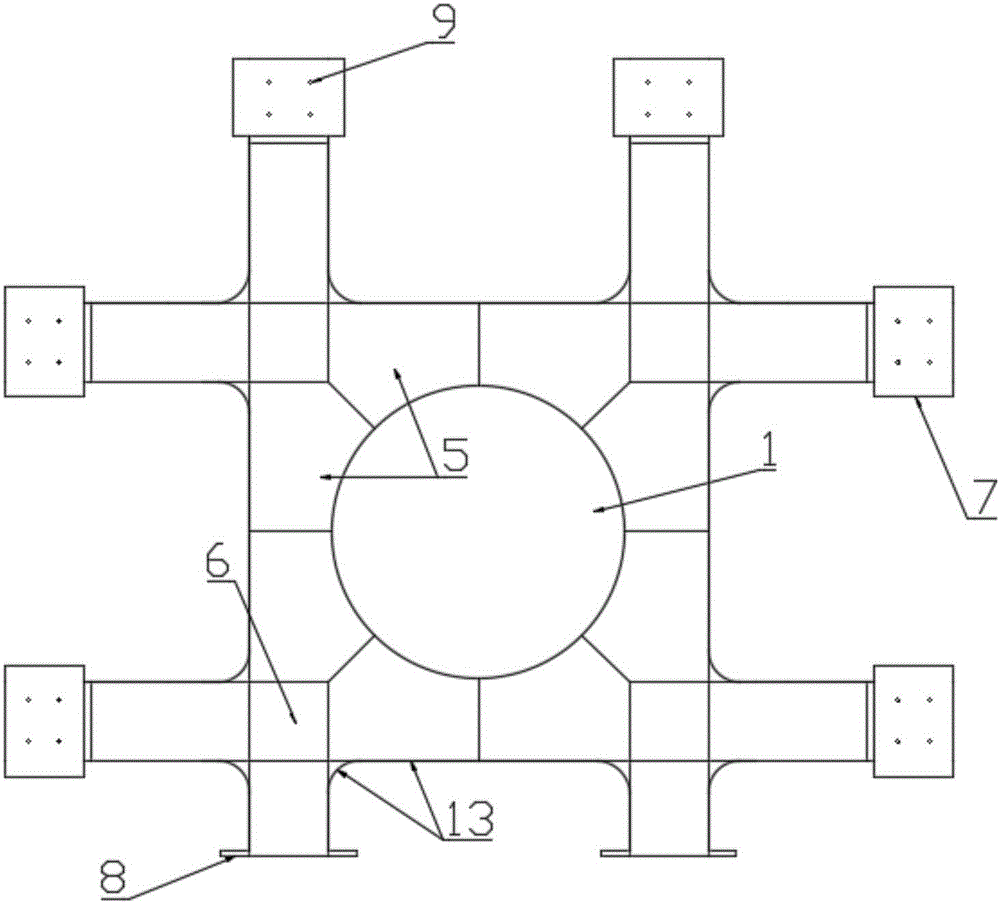

[0022] to combine Figure 1 to Figure 6 , the present invention is a well-shaped symmetrical structure as a whole, the whole bracket is symmetrically distributed about the middle longitudinal section, and the whole bracket is symmetrically distributed about the middle transverse section; Beams and 4 Z-shaped lap-jointed longitudinal beams, the end of the horizontal lap-joint beam is designed as a horizontal support, which is lapped and fixed with the platform; the end of the horizontal bolted beam is designed as a vertical surface structure, which is bolted and fixed with the platform; Z After the type overlapping longitudinal beam is extended from the bracket to both sides for a small distance, it extends vertically upward to a certain height, and then is fixed on the platform by horizontal overlapping. There is no welding connectio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap