A common oil-water plunger pump

A general-purpose, plunger pump technology, applied to pumps, parts of pumping devices for elastic fluids, multi-cylinder pumps, etc., can solve the problems of large volume and weight of the whole machine, substandard pressure, complex structure, etc. Achieve easy maintenance, direct friction avoidance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

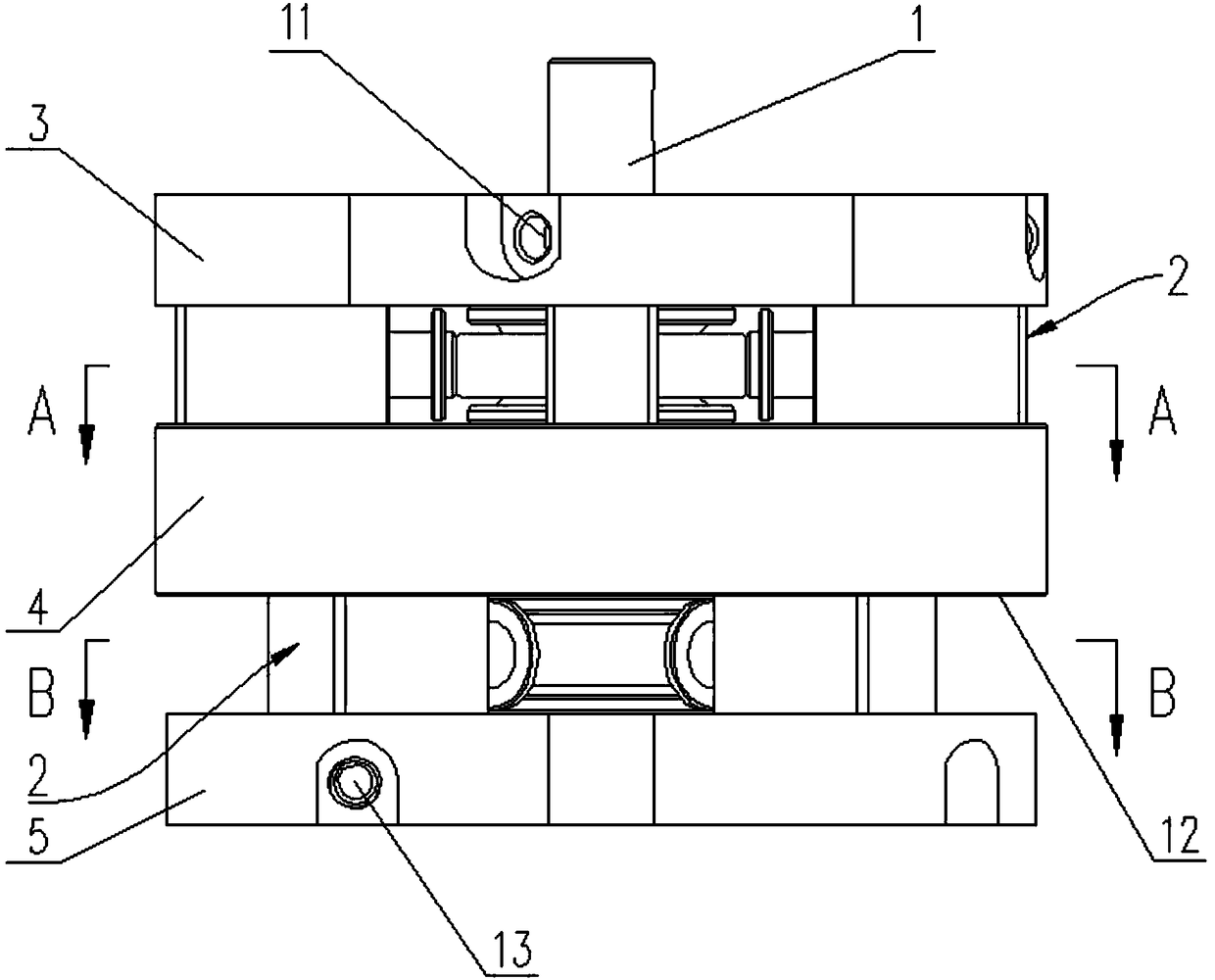

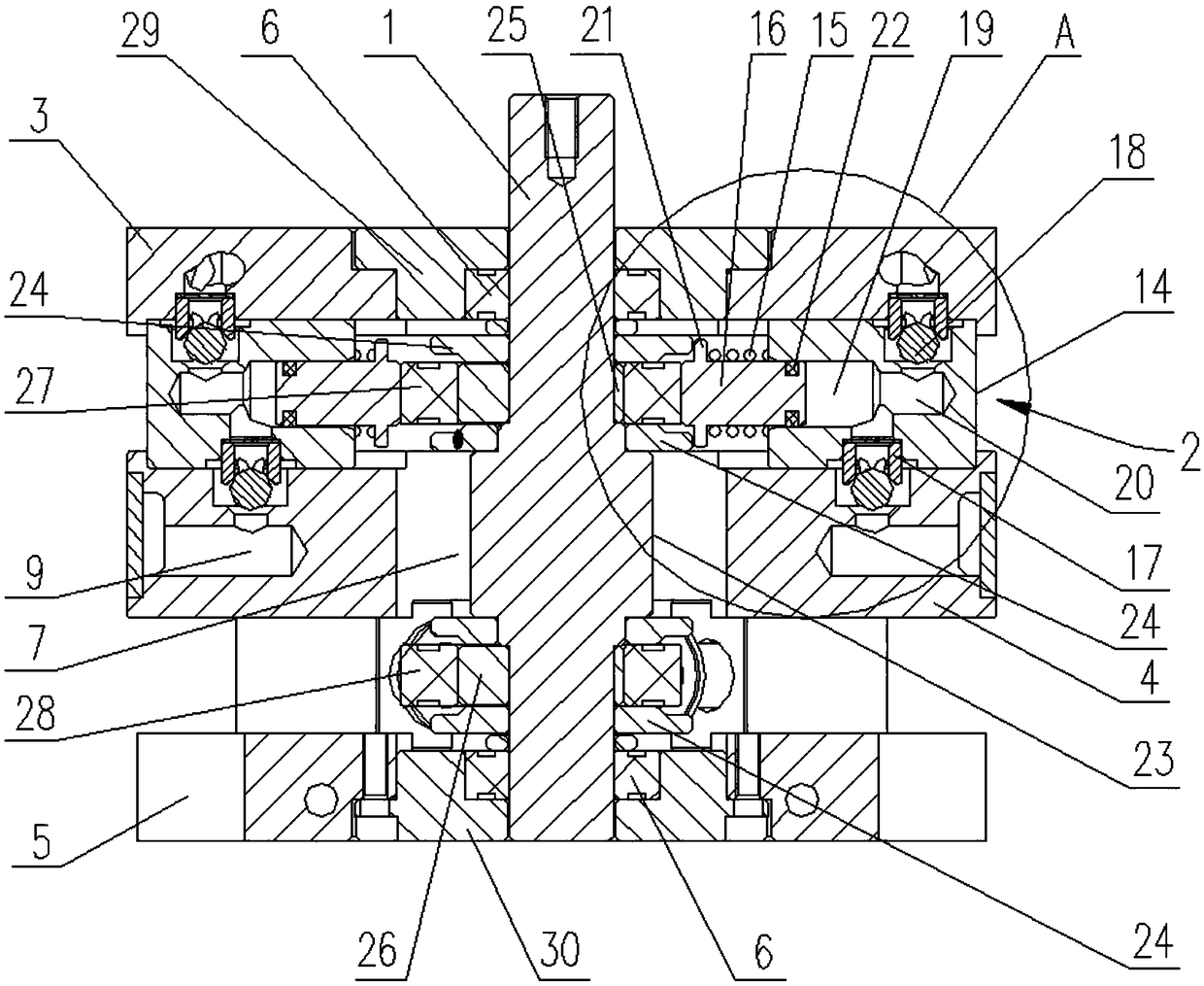

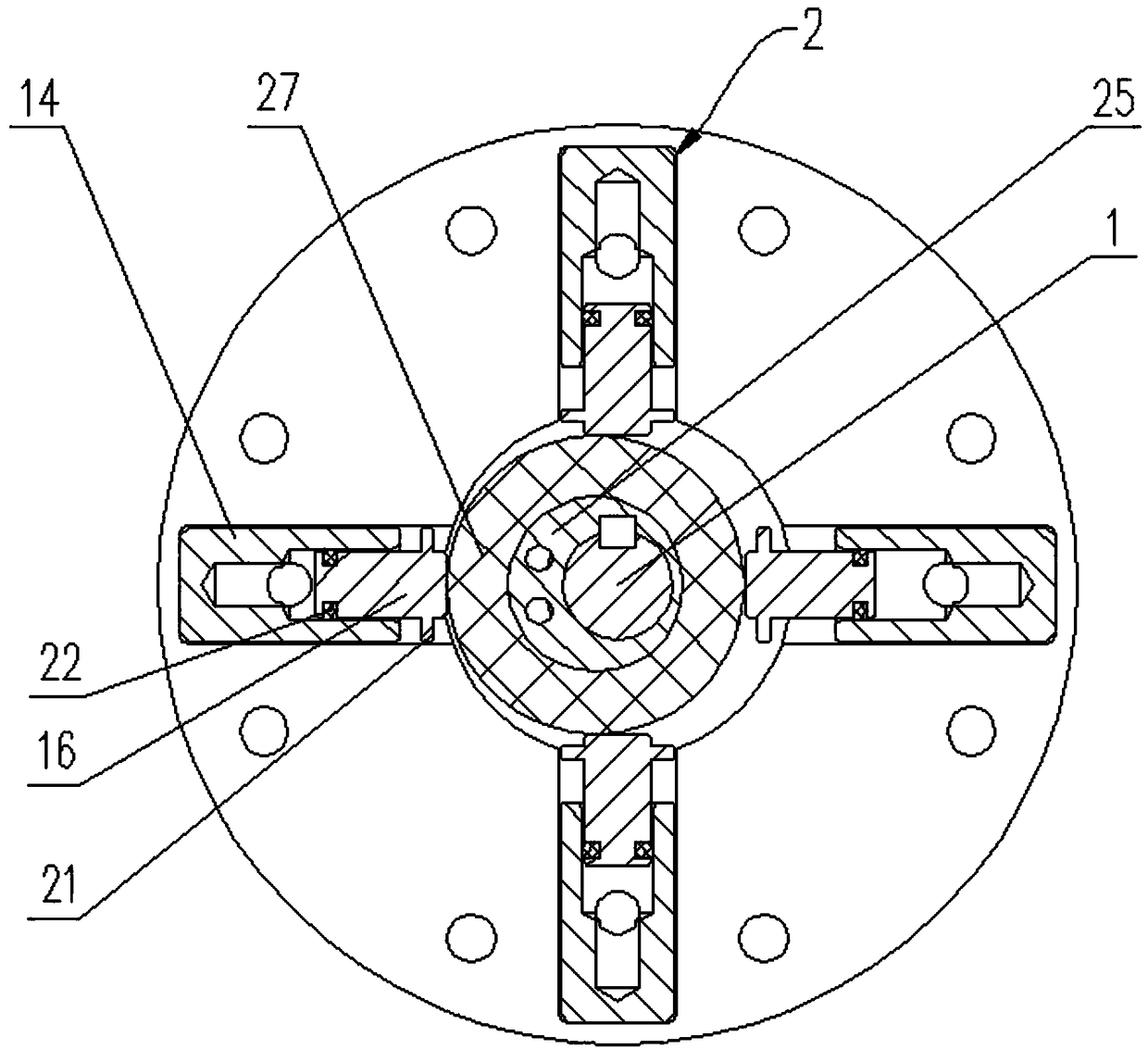

[0022] Such as Figure 1 to Figure 7As shown, an oil-water universal plunger pump includes a main shaft 1 and a plunger pressure module 2. The main shaft 1 is equipped with an upper cover plate 3, a middle plate 4 and a lower cover plate 5 sequentially from top to bottom. The main shaft 1, the upper cover plate 3 and the lower cover plate 5 are equipped with a bearing 6, and the center area of the middle plate 4 is provided with a through hole 7 whose inner diameter is greater than the outer diameter of the main shaft 1; the upper cover plate 3, the middle plate 4 and the lower cover plate 5 are respectively provided with an annular cavity 1 8, an annular cavity 2 9 and an annular cavity 3 10 surrounding the main shaft 1, and the upper cover 3 is provided with a pressure oil that communicates with the outside and the annular cavity 1 8 Passage one 11, the middle plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com