Gas-liquid combination novel driving cylinder

A technology for driving cylinders and cylinders, applied in the direction of fluid pressure actuation devices, etc., can solve the problems of increased failure rate of hydraulic valves, large space occupation, leakage and pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

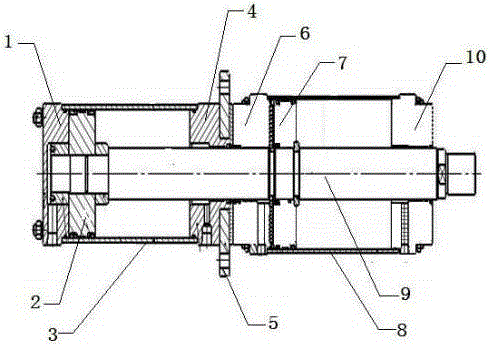

[0012] This embodiment provides a new gas-liquid combination drive cylinder, which is characterized in that: the gas-liquid combination new drive cylinder includes a cylinder rear end cover (1), a cylinder piston (2), a cylinder barrel (3), and a cylinder front cover (4), connecting flange (5), oil cylinder rear end cover (6), oil cylinder piston (7), oil cylinder barrel (8), common piston rod (9), oil cylinder front end cover (10);

[0013] Among them: the air-hydraulic combination cylinder is composed of a cylinder and an oil cylinder connected by a connecting flange (5), in which the rear end cover (1) and the front end cover (4) of the cylinder are respectively installed on both ends of the cylinder barrel (3), In addition, a cylinder piston (2) is provided near the rear end cover (1) of the cylinder, and a common piston rod (9) is provided at the center of the cylinder piston (2). barrel (8), the joint is provided with an oil cylinder rear end cover (6), and then an oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com