Five-way oil way structure of frequency control asynchronous motor brake for top drive

A technology of asynchronous motor and variable frequency speed regulation, which is applied in the direction of brake types, brake parts, mechanical equipment, etc., can solve the problems of high cost, unbalanced oil circuit distribution length, complex oil circuit structure, etc., and achieve fewer numbers and types, The installation and maintenance are convenient and fast, and the structure of the oil circuit is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

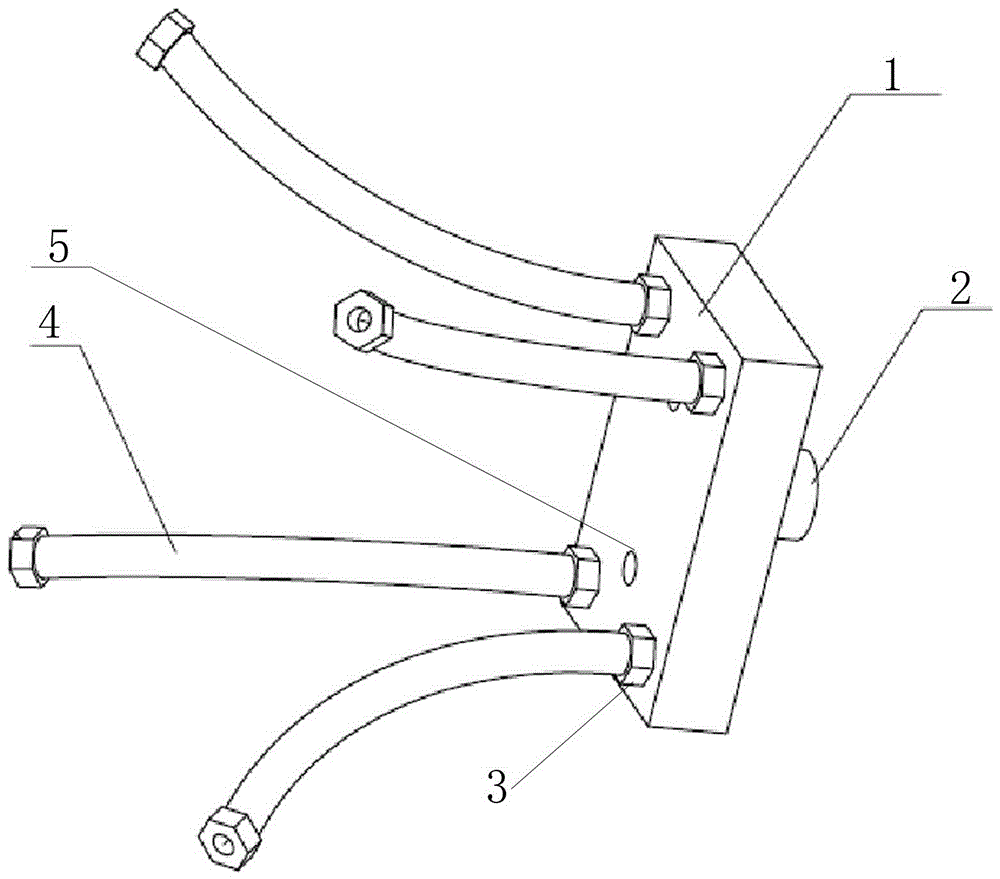

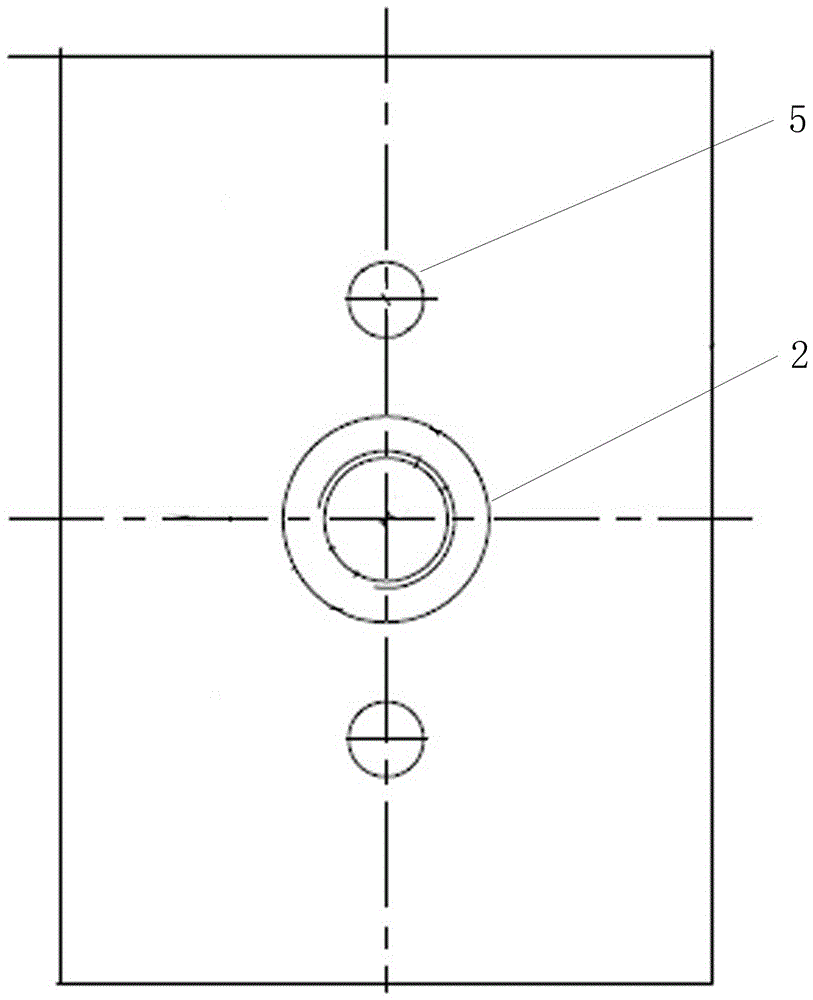

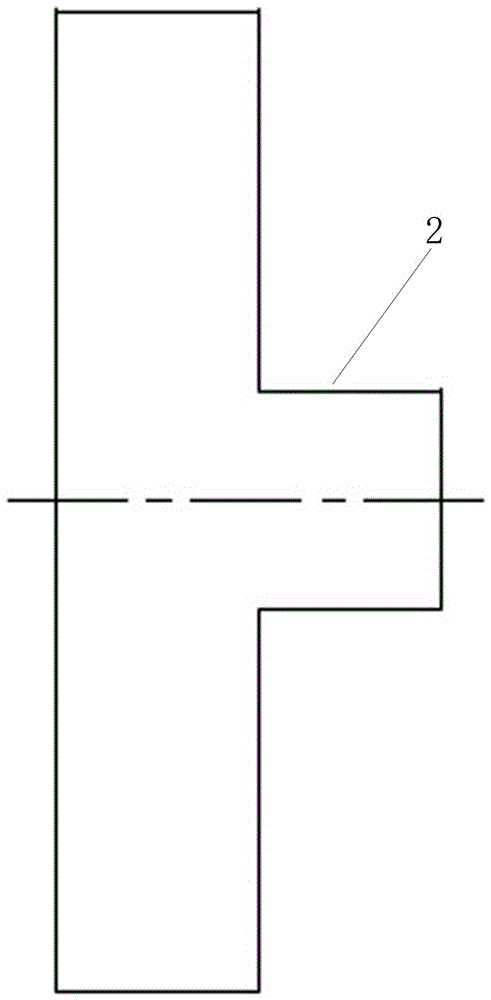

[0021] A five-way oil circuit structure for a top-drive variable-frequency and variable-speed asynchronous motor brake includes an oil circuit five-way 1 with a cavity structure inside; one side wall of the oil circuit five-way 1 is provided with an oil inlet 2, and Four oil outlets 3 are opened on the other side wall of the oil passage bottom bracket 1 opposite to the side wall provided with the oil inlet 2.

[0022] An oil outlet pipe 4 is connected to each of the four oil outlets 3.

[0023] The oil outlet pipe 4 and the oil outlet 3 are connected by a threaded structure.

[0024] The oil channel bottom bracket 1 is welded by high-strength steel plate and has a rectangular shape; the oil inlet 2 is opened on one of the two largest sides of the rectangle, and the four oil outlets 3 are opened on the other largest side. Above and close to the four corners of the side respectively (such as figure 1 , 4 Shown).

[0025] The oil channel bottom bracket 1 is provided with a pair of thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com