Multifunctional valve assembly for pump

A valve assembly, multi-functional technology, used in lubrication pumps, aircraft parts, engine components, etc., can solve the problems of reducing the weight of the lubricating oil system and the complexity of the aviation lubricating oil system, reducing the number of accessories, small size, and improving reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

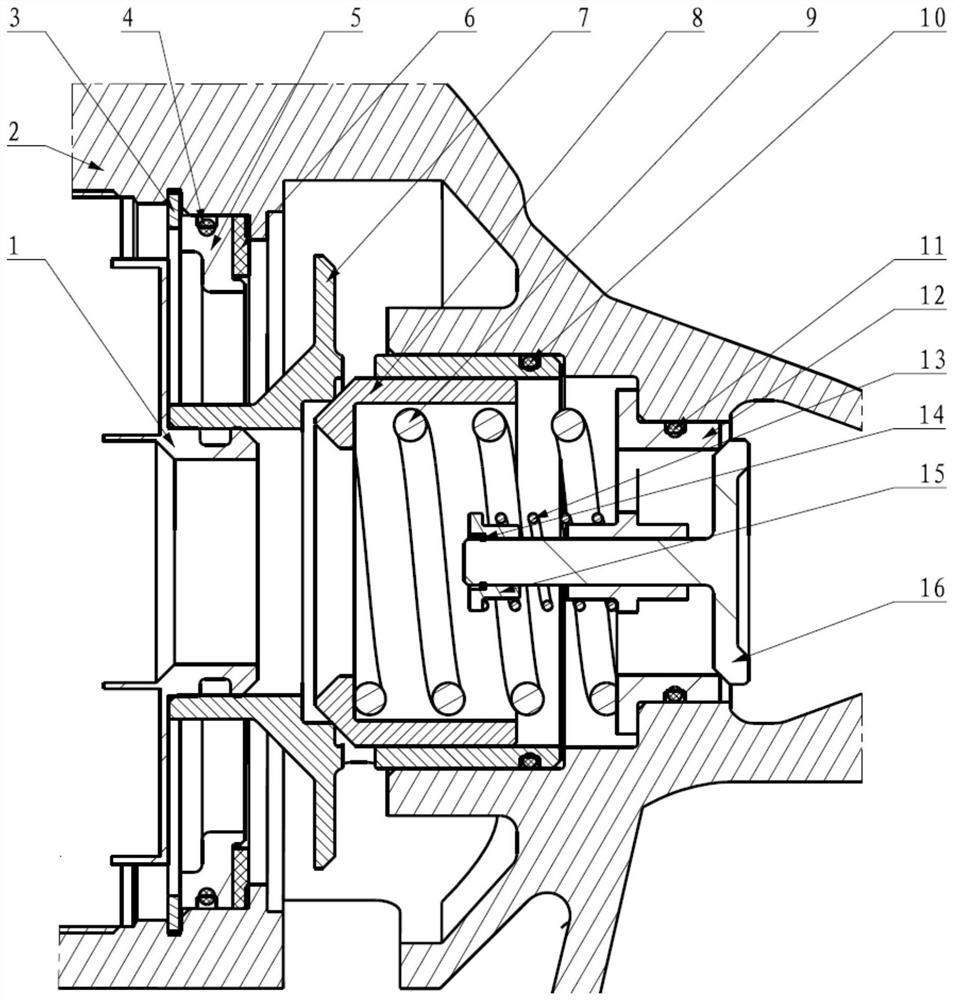

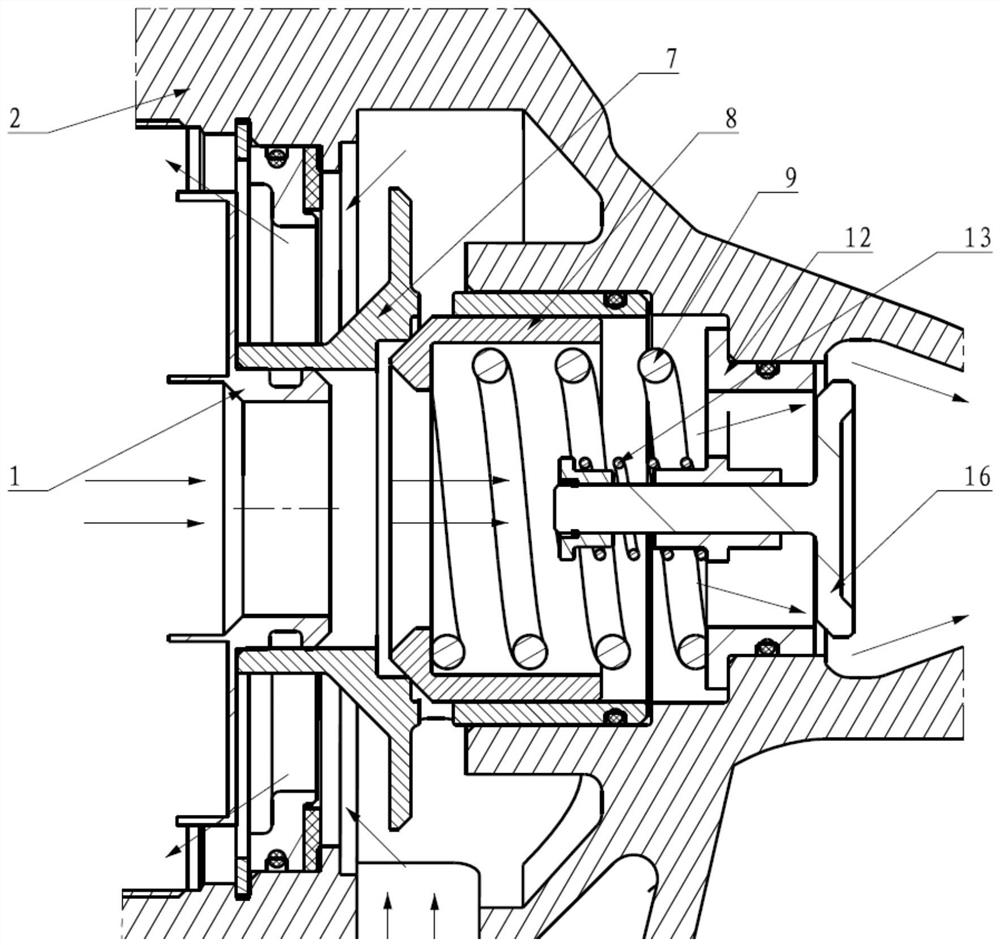

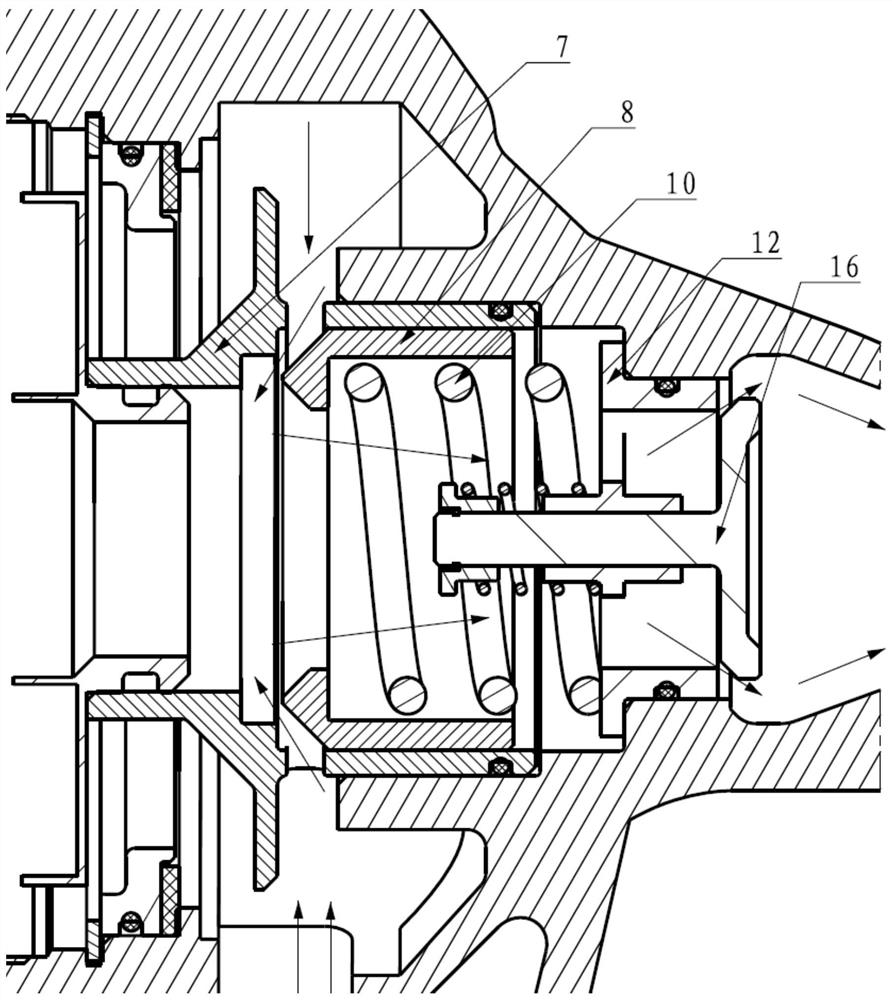

[0028] The multifunctional valve assembly for pumps of the present invention highly integrates the functions of various valves in pump products. By sharing an anti-siphon valve body with the bypass valve and the cut-off valve, the bypass valve and the cut-off valve The same spring and cut-off valve body are used. The corresponding structure is set in the pump housing to fix and limit the valve assembly. The limit body is connected to the left oil pipeline. When the oil pipeline is disassembled, the limit body is disassembled together. Next, the cut-off valve is in contact with the sealing retainer under the action of the first spring, and the sealing gasket is compressed to prevent oil leakage. Each moving part of the assembly moves an appropriate opening degree, thereby realizing the function of the bypass valve and the anti-siphon valve.

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com