Vacuum absorber

A vacuum adsorber and vacuum adsorption technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of falling off of the adsorption plate, reducing work efficiency, increasing production cost, etc., and improving the adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

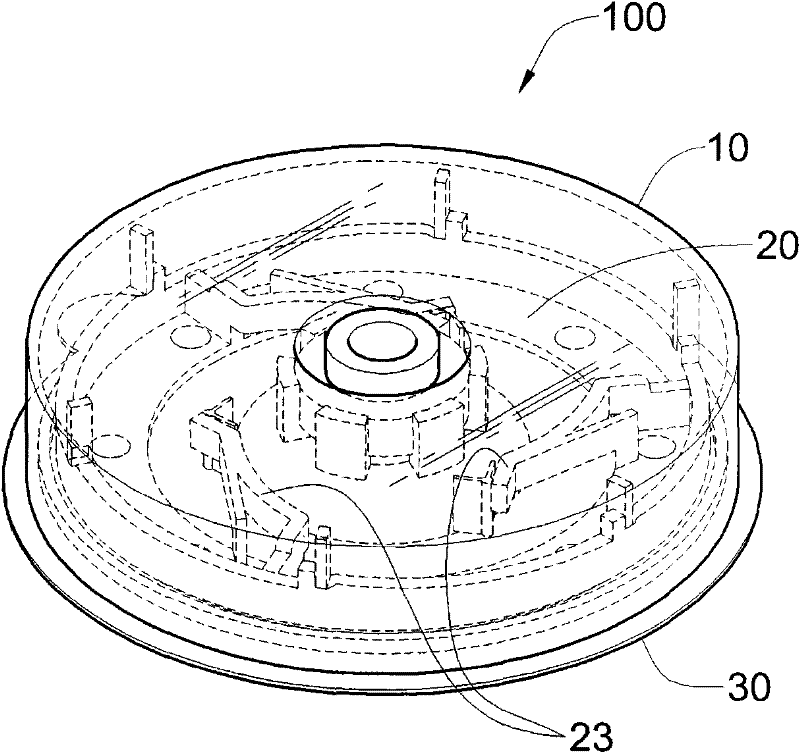

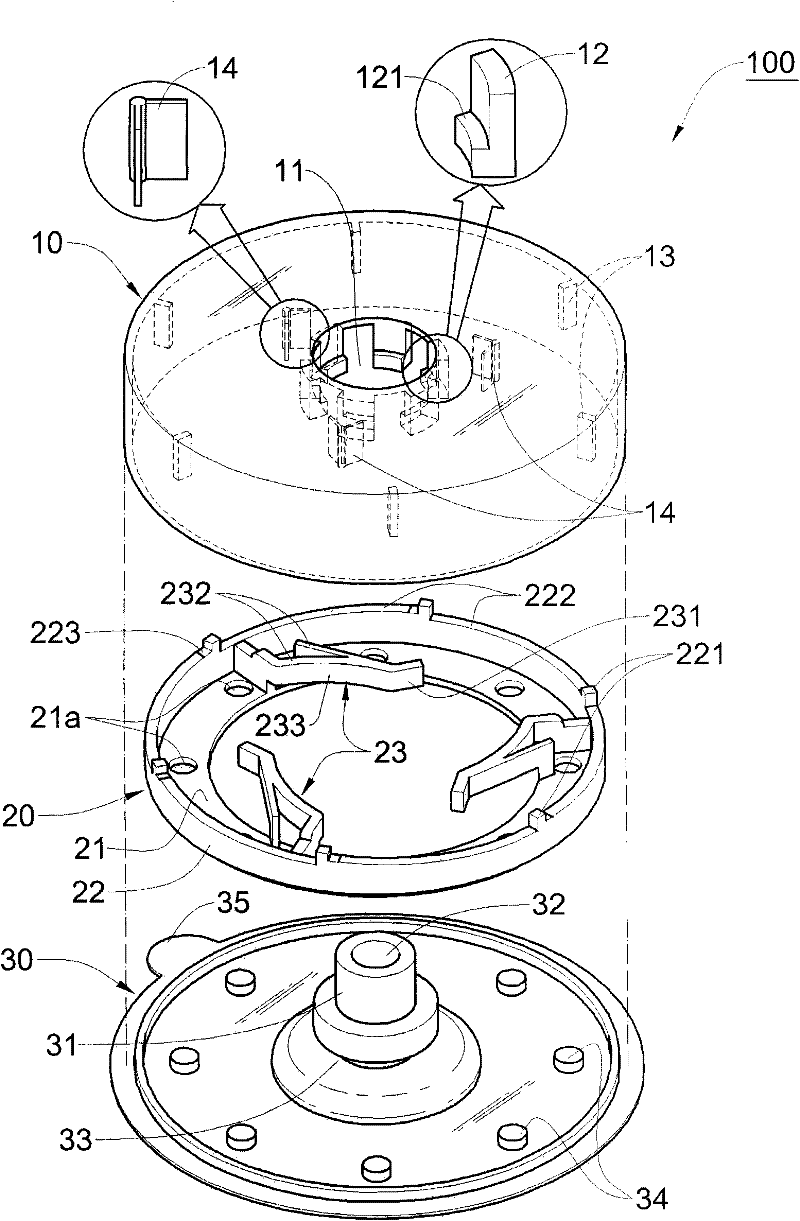

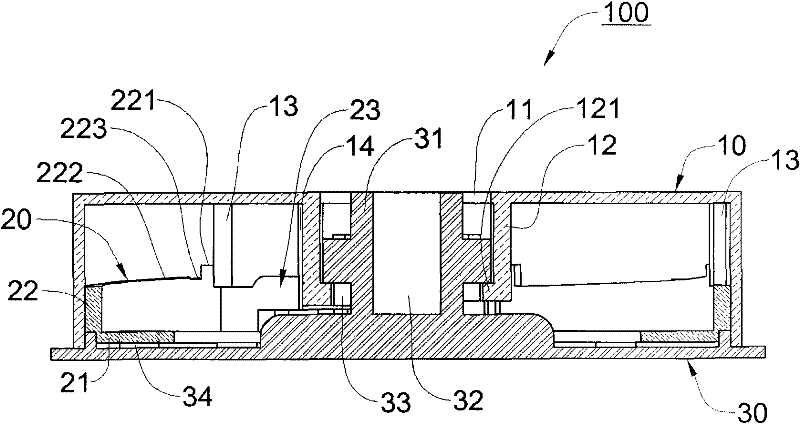

[0047] The following with attached Figure 1 to Figure 6b The vacuum adsorber of the present invention will be further described in detail.

[0048] The present invention implements a vacuum absorber 100 that is vacuum-adsorbed to the adsorption surface a in order to hang various objects such as towels, bath towels, toilet paper, etc. on the smooth surface or flat surface such as glass and ceramic tiles.

[0049] Such as Figure 1 to Figure 3 As shown, the vacuum absorber 100 consists of a rotatable cover 10 located on the upper side of the vacuum absorber 100; located on the inner side of the lower part of the cover 10, the vacuum absorber 100 is attached to the vacuum adsorption surface a. The adsorption plate 30 on the adsorption surface a is located on the lower inner side of the cover 10 and is arranged between the cover 10 and the adsorption plate 30 in order to be adsorbed on the adsorption plate 30, and with the rotation of the cover 10 The height adjustment attachme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com