Heat gun and multifunctional operating head thereof

A hot air gun, multi-functional technology, applied in electric heating devices, manufacturing tools, metal processing equipment and other directions, can solve the problems of difficult storage of accessories, wrong use of accessories, waste of time, etc., and achieve the effect of reducing the number of accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

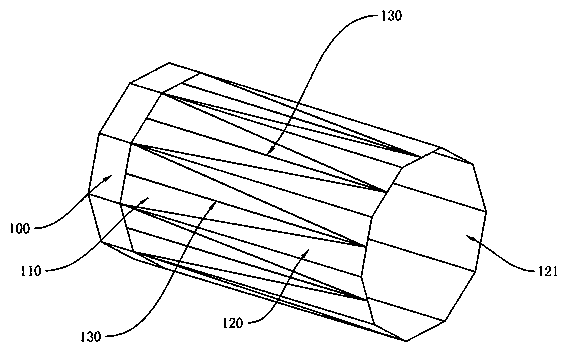

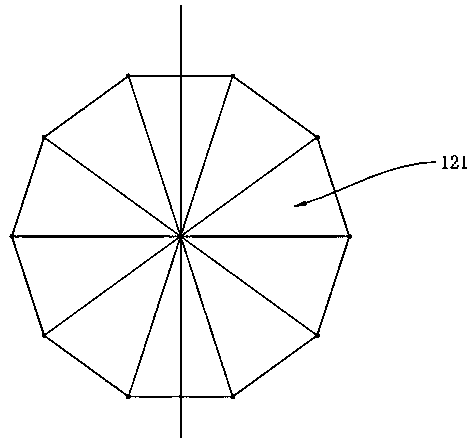

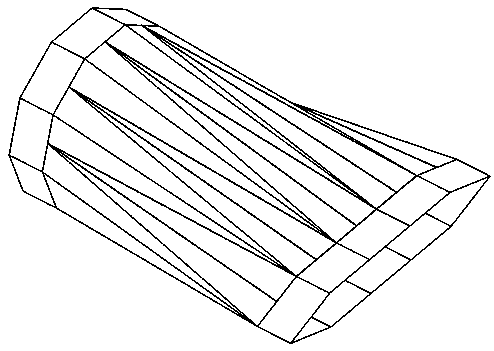

[0027] see Figure 1-Figure 2 , the multifunctional working head of the heat gun in this embodiment includes the mounting sleeve 100, the first polygonal side 110, and the second polygonal side 120. In this embodiment, the first polygonal side 110, the second polygonal side The two polygon sides 120 are all selected triangular sides, the first polygon side 110 and the second polygon side 120 are distributed at intervals, and one end of the first polygon side 110 is connected to the mounting sleeve 100 The other end is connected and fixed to one end of the second polygonal side 120 ; the first polygonal side 110 and the second polygonal side 120 jointly enclose the air outlet 121 .

[0028] The first polygonal side 110 and the second polygonal side 120 are connected with creases 130 (or folds), which can be folded through the creases 130 during use. This des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com