A device with remote control shifting function and its control method

A remote control and functional technology, applied in the direction of mechanical control devices, transmission control, and components with teeth, etc., can solve problems such as complex structure, low integration, difficulty in shifting, steering, and braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained in conjunction with specific drawings.

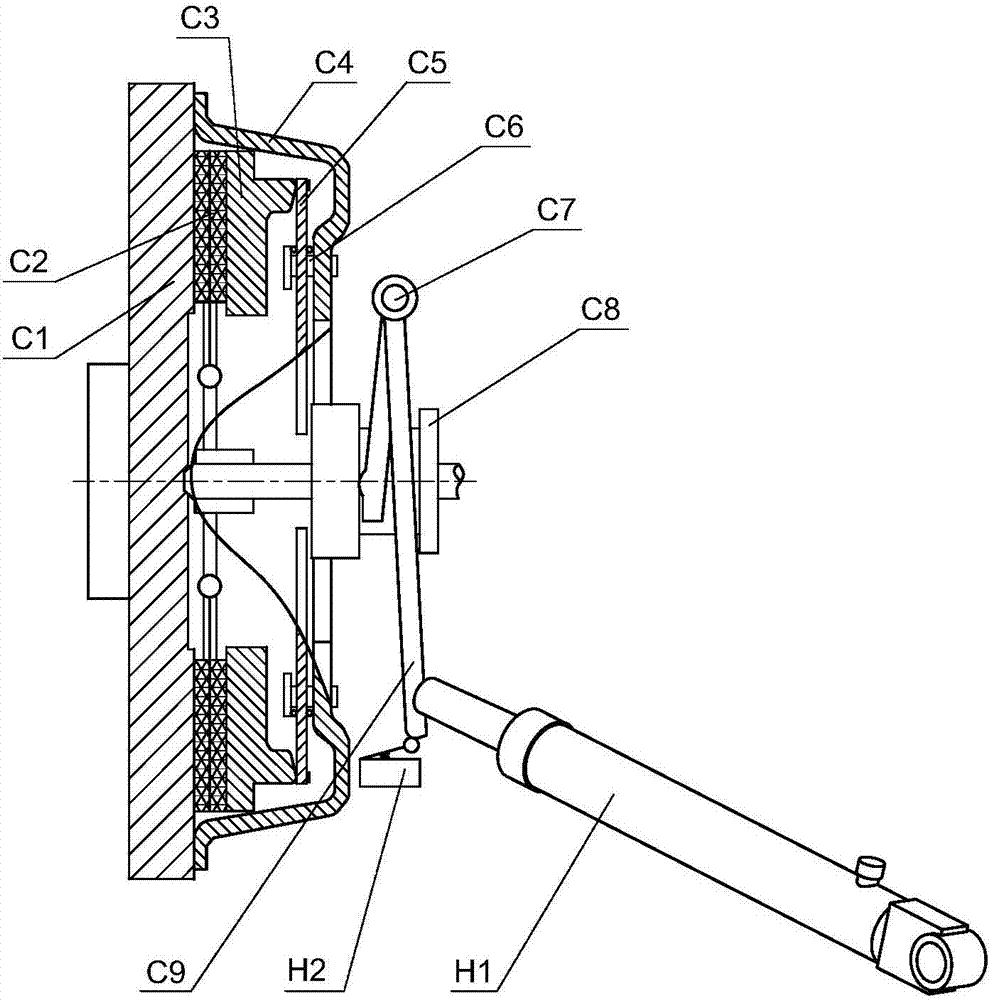

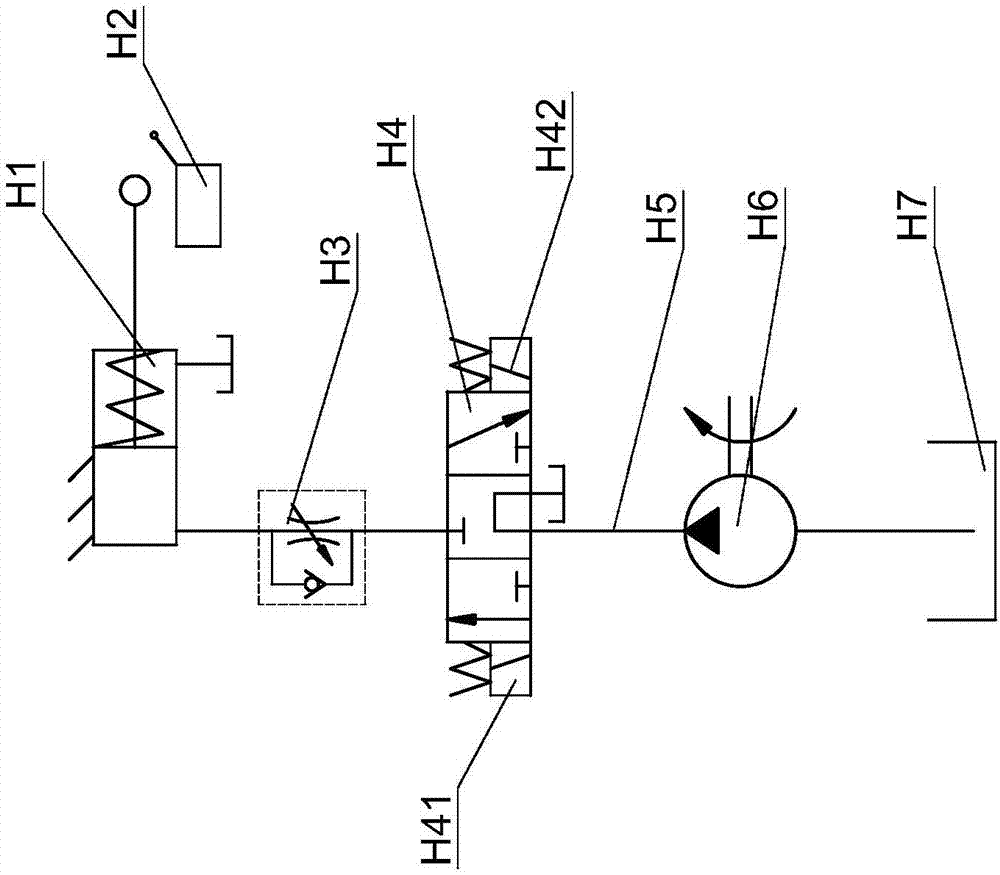

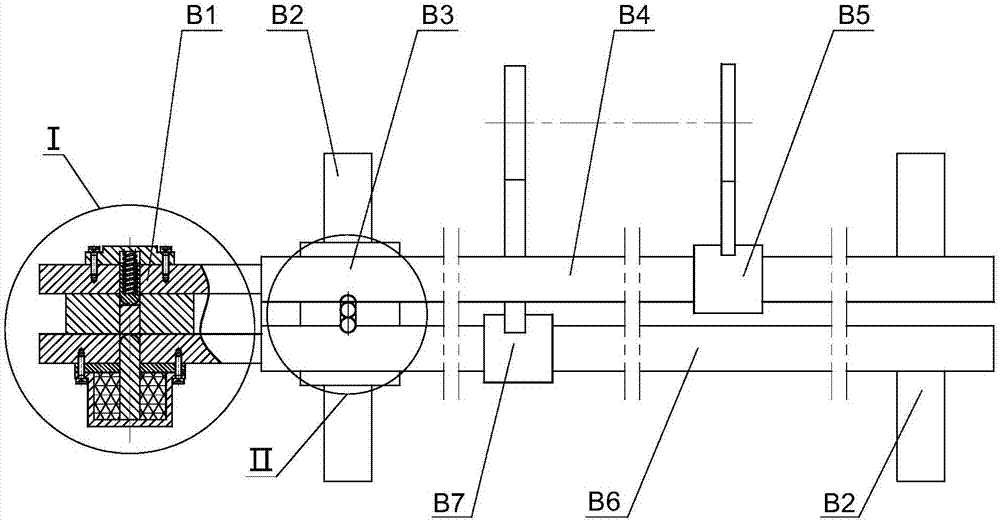

[0048] See Figure 1 ~ Figure 2 A device with a remote control shifting function includes a clutch operating mechanism, a shift fork shifting mechanism, a shifting operating mechanism and an automatic control mechanism. Among them, the clutch operating mechanism, the shifting operating mechanism, and the shifting operating mechanism are separate from the automatic The control mechanism is connected, and the specific structure of each mechanism is as follows:

[0049] The clutch operating mechanism includes engine flywheel C1, clutch disc C2, pressure plate C3, clutch housing C4, elastic release component C5, spring support pin C6, release fork shaft C7, release bearing C8, release fork C9, hydraulic cylinder H1, and half Clutch position switch H2, one-way throttle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com