Control valve used for electric heating faucet and work method of control valve

A working method and technology for controlling valves, applied in valve heating/cooling devices, valve operation/release devices, valve details, etc., can solve problems such as pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to elaborate on the present invention.

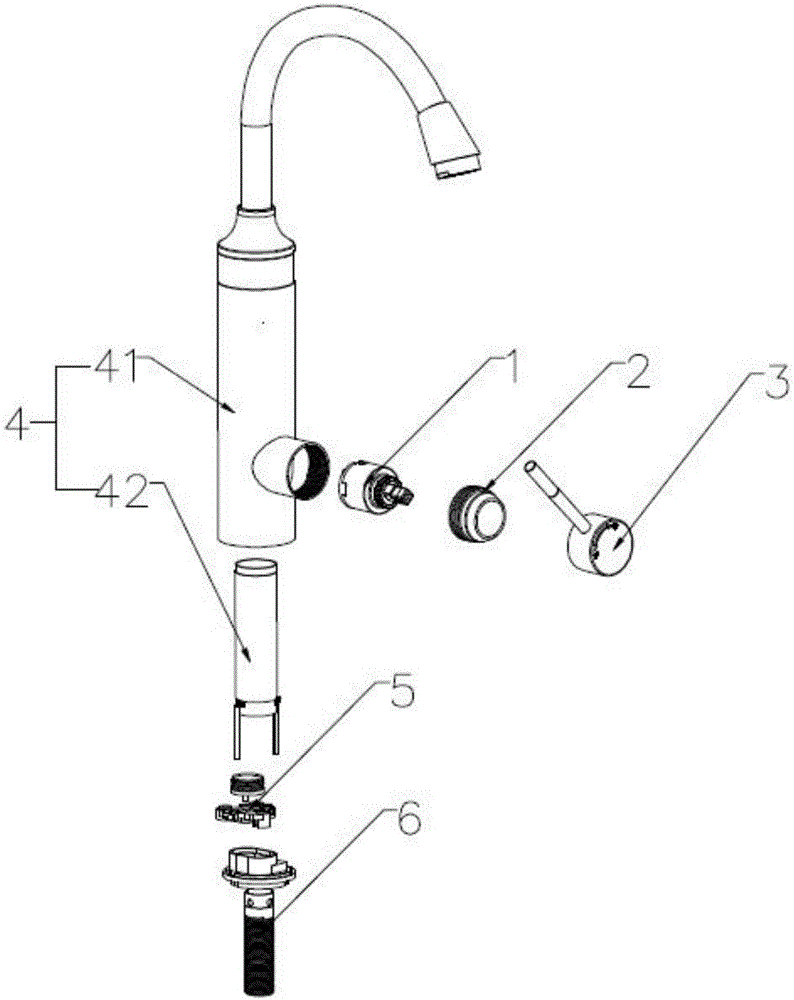

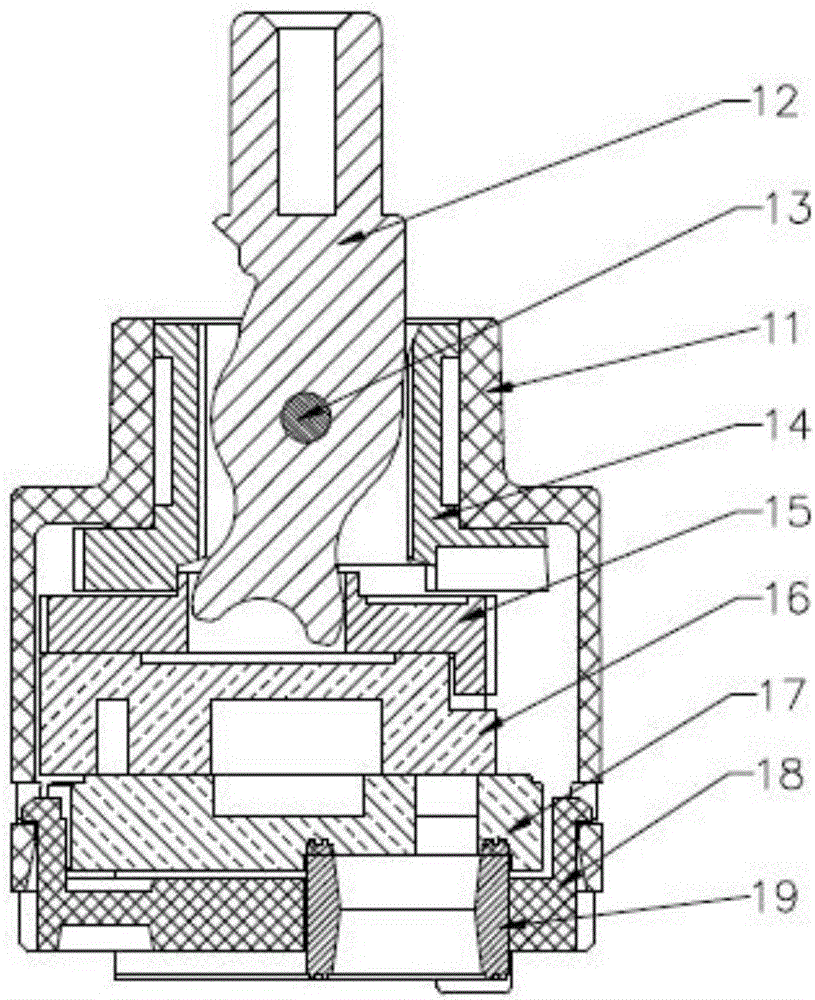

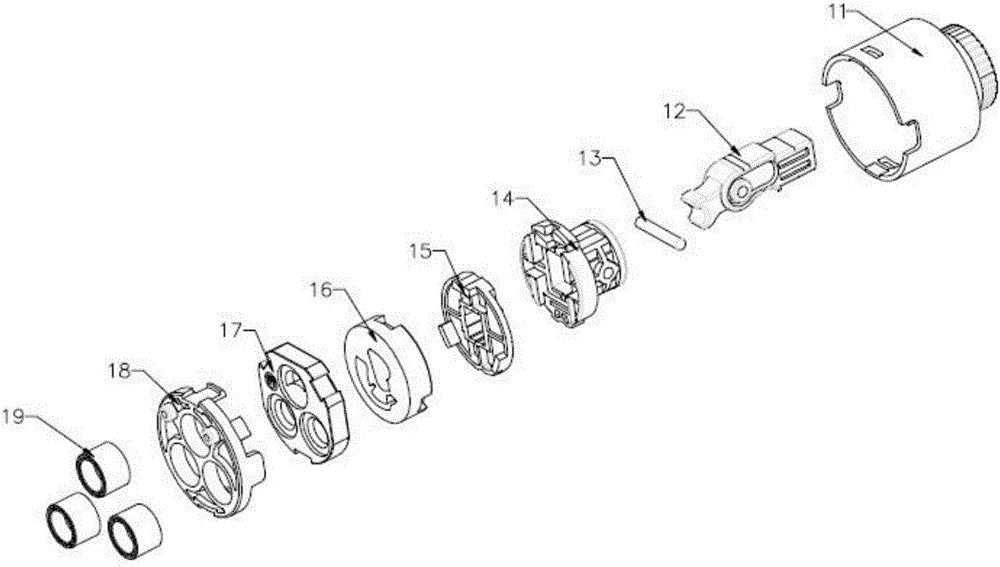

[0040] figure 1 It is an exploded view of the coordination of the control valve and the electric heating faucet in the present invention; figure 2 It is a sectional view of the control valve in the present invention; image 3 For the explosion diagram of the control valve in the present invention, please refer to Figure 1 to Figure 3 As shown, a preferred control valve for an electric heating faucet is shown, including a valve housing 11, a moving ceramic disc assembly and a fixed ceramic disc assembly arranged in the valve housing 11, and the moving ceramic disc assembly is also connected with the The pressing rod assembly is connected, and the pressing rod assembly controls the movement of the braking tile assembly, thereby adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com