Furnace bottom machine oblique rail base and manufacturing method thereof

A technology of inclined rail seat and inclined rail, which is applied in the field of furnace bottom mechanical inclined rail seat and its production, can solve problems such as difficulty in ensuring installation accuracy, and achieve the effects of high installation accuracy, easy manufacturing, and reduced manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

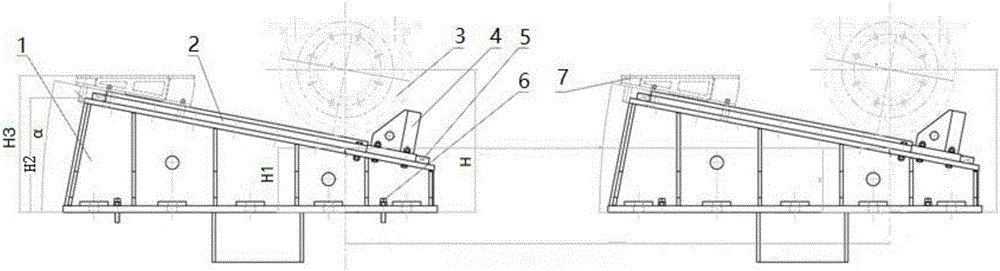

[0022] A furnace bottom mechanical ramp seat of the present invention is composed of a ramp seat 1, a ramp plate 2, a stopper 4, an iron stopper 5, and an adjustment bolt 6; the ramp plate 2 is installed on the upper surface of the ramp seat 1, and the stopper 4 Installed on the low end of the ramp plate 2, the iron stopper 5 is installed on the stopper 4 rear portion.

Embodiment 2

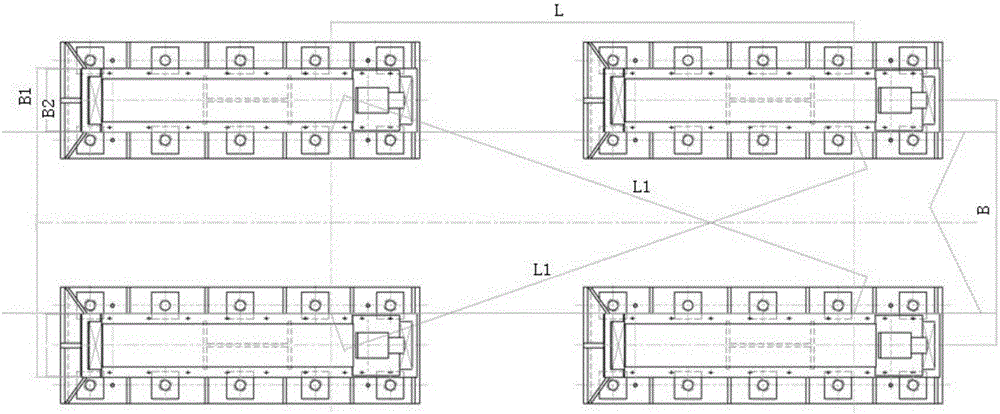

[0024] The ramp seat 1 of the present invention is fixedly connected with the civil foundation through anchor bolts. When installing, there are multiple sets of ramp seats arranged in two columns. During installation, the vertical marking line of the ramp seat 1 coincides with the determined roller spacing. Example 3

Embodiment 3

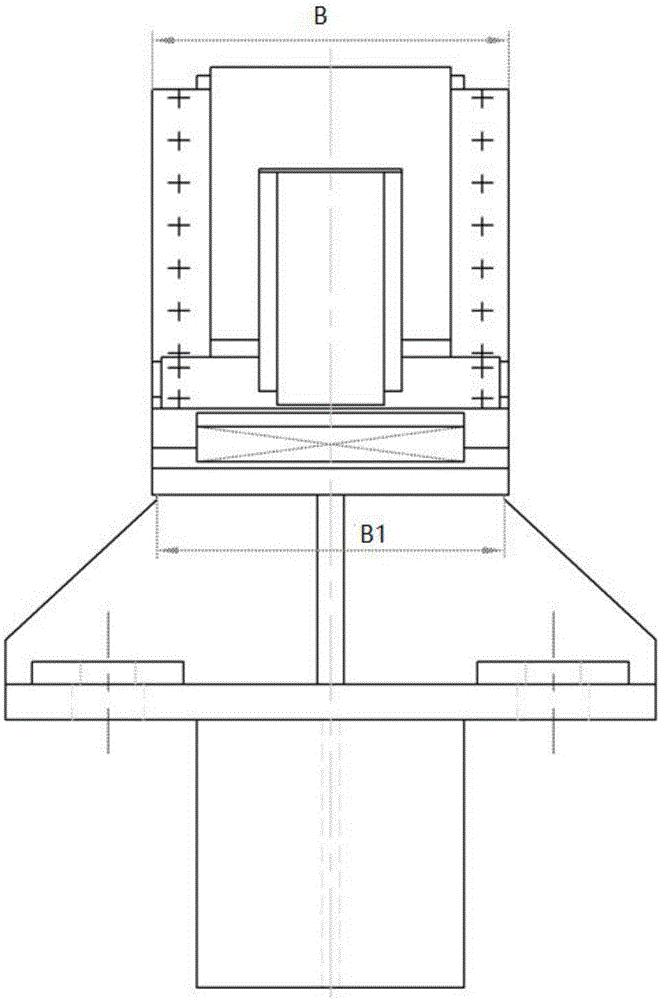

[0025] The ramp seat of the present invention determines the elevation of the ramp seat by the ramp seat H1 elevation point (sample punch eye); the ramp seat mounting module 7 only plays the role of looking for the level of the ramp seat when the H1 elevation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com