Test tool support

A technology of checking fixtures and chassis, which is applied in the field of checking fixture manufacturing, can solve problems such as the difficulty of adjusting the checking fixture bracket, and achieve the effect of solving difficult adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

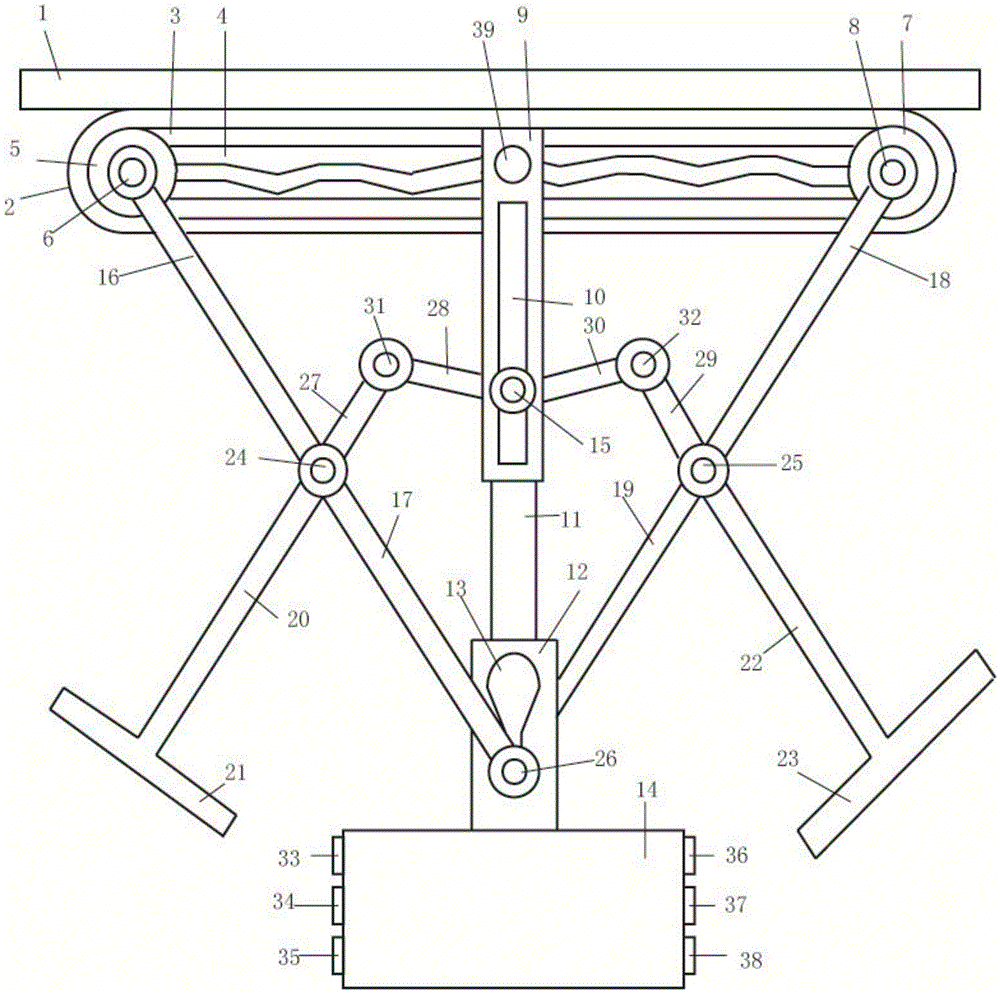

[0019] This embodiment includes a wear-resistant connecting plate 1, a checker bracket 2, a sliding groove 3, a zigzag slideway 4, a limiting plate A5, a fixed shaft A6, a limiting plate B7, a fixed shaft B8, a sliding shaft 9, and a stretching ruler slide Road 10, stretching ruler 11, lock 12, lock hole 13, fixed base 14, stretching ruler positioning bolt 15, connecting frame A16, connecting frame B17, connecting frame C18, connecting frame D19, stretching frame A20, fixing Handle A21, stretching frame B22, fixed handle B23, fixed shaft C24, fixed shaft D25, fixed shaft E26, connecting frame E27, connecting frame F28, connecting frame G29, connecting frame H30, fixed shaft F31, fixed shaft G32, limit Slot A33, limiting groove B34, limiting groove C35, limiting groove D36, limiting groove E37, limiting groove F38, sliding shaft positioning pin 39, sliding groove 3 is inside the checking fixture bracket 2, and zigzag slideway 4 is inside Inside the sliding groove 3, the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com