Device and method for fast counterweight adjustment of rotating machinery dynamic balance

A technology of rotating machinery and adjusting devices, which is applied in static/dynamic balance testing, measuring devices, testing of machine/structural components, etc. It can solve the problems of heavy workload of on-site operators, cumbersome and complicated operation procedures, and cumbersome on-site safety measures, etc. problems, to achieve the effect of saving dynamic balance time, improving dynamic balance accuracy, and facilitating adjustment and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

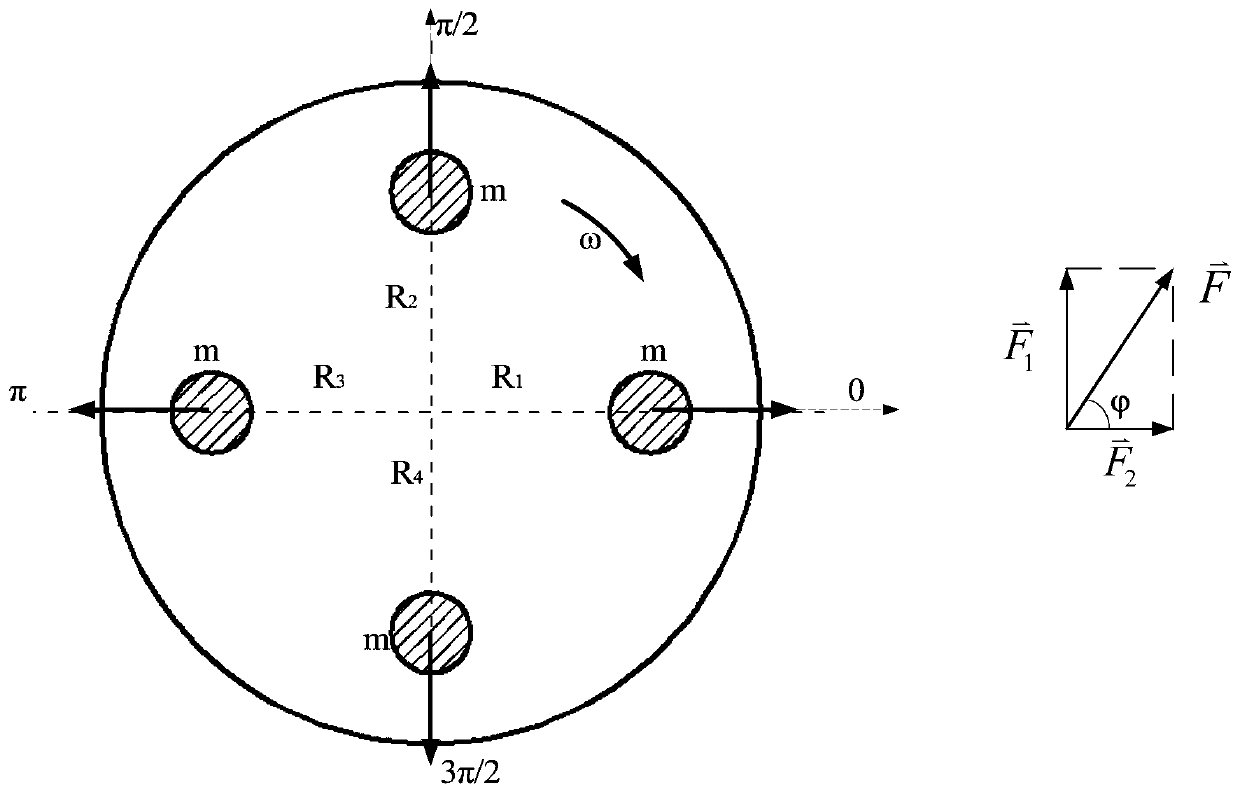

[0035] see Figure 1-Figure 7 , this embodiment is installed on the rotating shaft of the rotary machine. In this example:

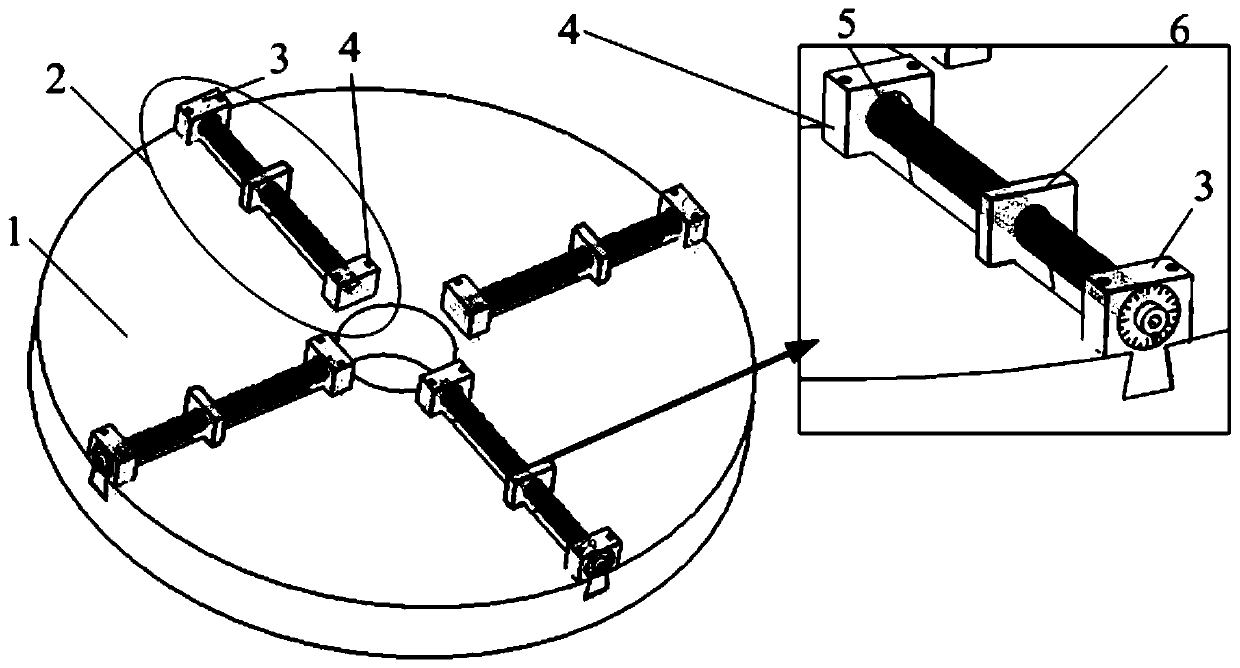

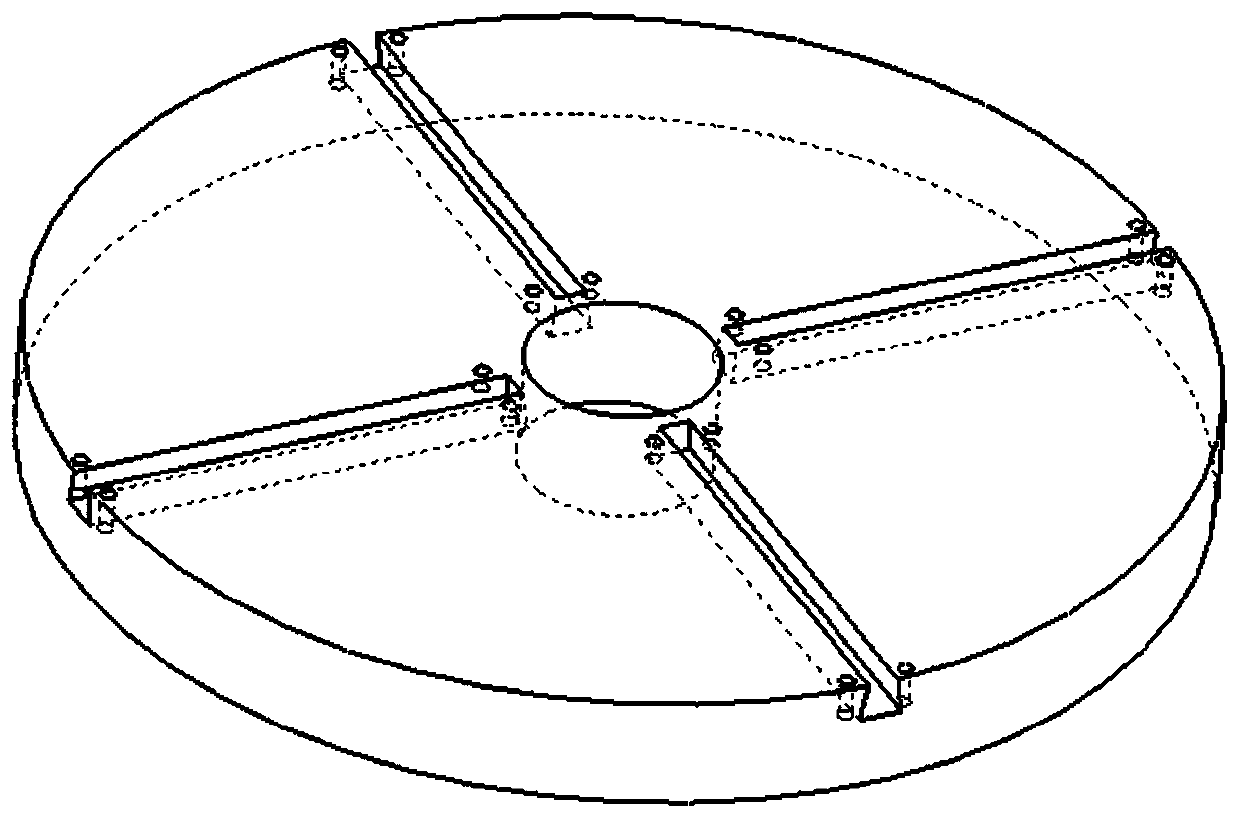

[0036] The dynamic balance quick counterweight adjustment device includes: a balance plate with 4 dovetail grooves, such as figure 2 and image 3 As shown, and 4 sets of counterweight adjustment parts installed on the balance plate.

[0037] The four sets of counterweight adjustment components are installed vertically in the dovetail groove of the balance plate two by two, and are fixed with the balance plate by bolts.

[0038] The counterweight adjustment part is composed of an inner bearing seat, a screw rod, a counterweight block and an outer bearing seat.

[0039] The inner bearing seat as described Figure 4 Consists of an inner bearing base and 1 ball bearing assembly as shown. The inner bearing base has a trapezoidal bottom, which is convenient for assembly with the dovetail groove on the balance plate.

[0040] The screw rod as Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com