Roadway stability measurement and evaluation vehicle and its use method

A stability and roadway technology, applied in the field of roadway stability measurement and evaluation vehicles, can solve the problems of bottom drilling, inclination, and low rigidity of weak bottom plates, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

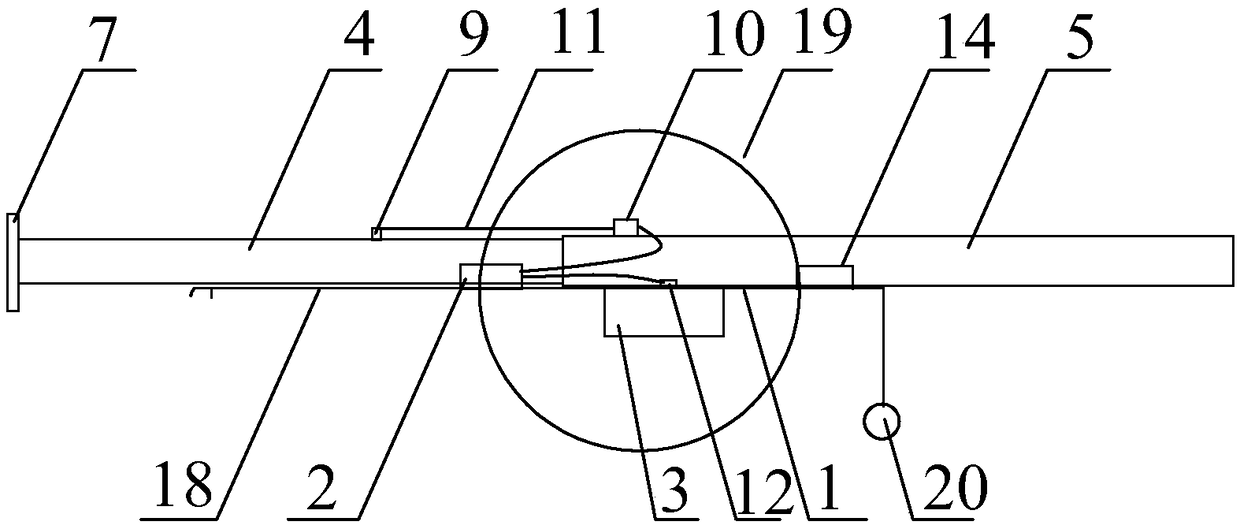

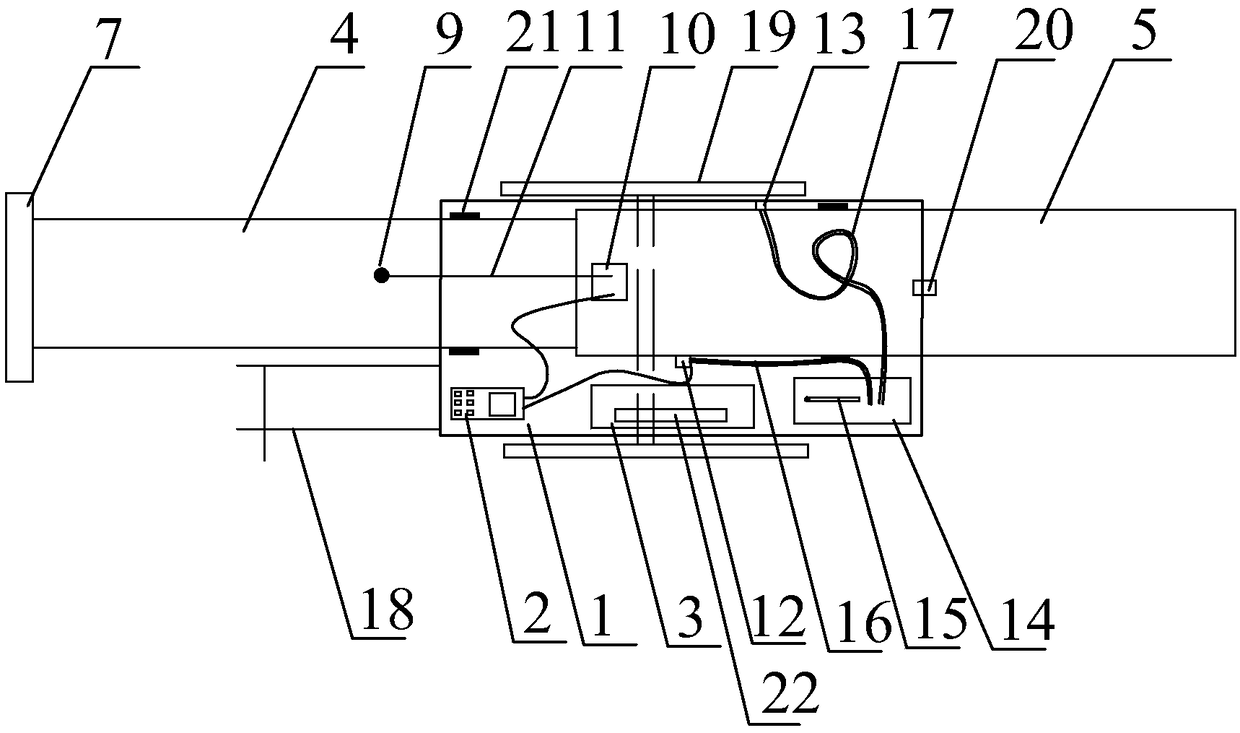

[0046] like Figure 1-Figure 8 As shown, a roadway stability measurement and evaluation vehicle includes a vehicle body and an improved single pillar detachably fixed on it;

[0047] The car body includes a compartment panel 1, on which the improved single pillar is detachably fixed, and on the compartment panel 1 are also provided with a manipulator 2 and a storage box 3, as well as a displacement measuring system connected with the manipulator 2, hydraulic pressure Measuring system and anchoring force testing system 22; the improved single pillar is connected to the displacement measuring system and the hydraulic measuring system respectively;

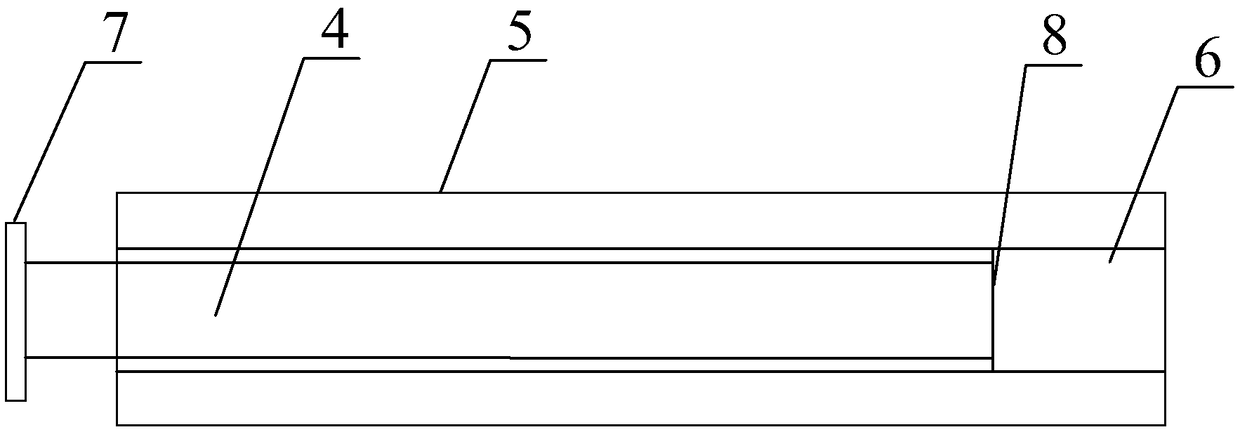

[0048] The improved single column is composed of an inner column 4 and an outer column 5 sleeved outside the inner column 4. The outer column 5 is a hollow structure with one end closed. The hollow part is an oil chamber 6. The inner column 4 is a structure with both ends closed. A top plate baffle 7 is provided, and a sealing plate...

Embodiment 2

[0067] A method of using the roadway stability measurement and evaluation vehicle of the present invention to carry out on-site measurement of the floor specific pressure at different locations of the whole roadway, comprising the following steps:

[0068] Step 1. Arrange measuring points: arrange a measuring point every 10m in the roadway area with flat terrain, and arrange a measuring point every 5m in the area where the slope of the terrain is greater than 8° or within 20m, and the difference between any height of the roadway is 500mm;

[0069] Step 2. Measurement: Use the roadway stability measurement and evaluation car, push it to the first measuring point, clean the bottom plate first, straighten the improved single pillar, and keep it in a vertical state. The bottom plate must be in full contact.

[0070] Open the valve on the high-pressure liquid injection pipe 16, it is advisable to pressurize the improved single pillar so that the top plate baffle plate 7 is no longer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com