An experimental method for testing rock fracture toughness under pore pressure conditions

A technology of pore pressure and fracture toughness, applied in the direction of using stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve the problem that the fracture toughness test result cannot be obtained accurately, does not consider pore pressure, cannot reflect problems such as the real situation of the formation, to achieve the effect of accurate fracture toughness, strong practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] An experimental method for testing rock fracture toughness under pore pressure conditions, comprising the following steps:

[0056] 1. Preparation of test pieces

[0057] Use a rock slicer to cut the rock material into cuboid specimens 17 with a length, width, and height of 76mm, 30mm, and 38mm, and then use a wire cutting saw to cut a prefabricated crack with a thickness of 1mm and a length of 15mm in the middle of the specimen 17.

[0058] 2. Sealing and fixing of test piece

[0059] First, cover the processed test piece 17 and the two hole-pressing heads 15 with a thermoplastic tube. The thermoplastic tube should cover the seal on the hole-pressing head 15, but not cover the liquid injection port II, and then The thermoplastic tube is blown soft with a hot blower, and the thermoplastic tube seals the test piece 17 and the hole-pressing head 15. After the thermoplastic pipe is cooled, the sealing member and the thermoplastic pipe on the hole pressing head 15 are cru...

Embodiment 2

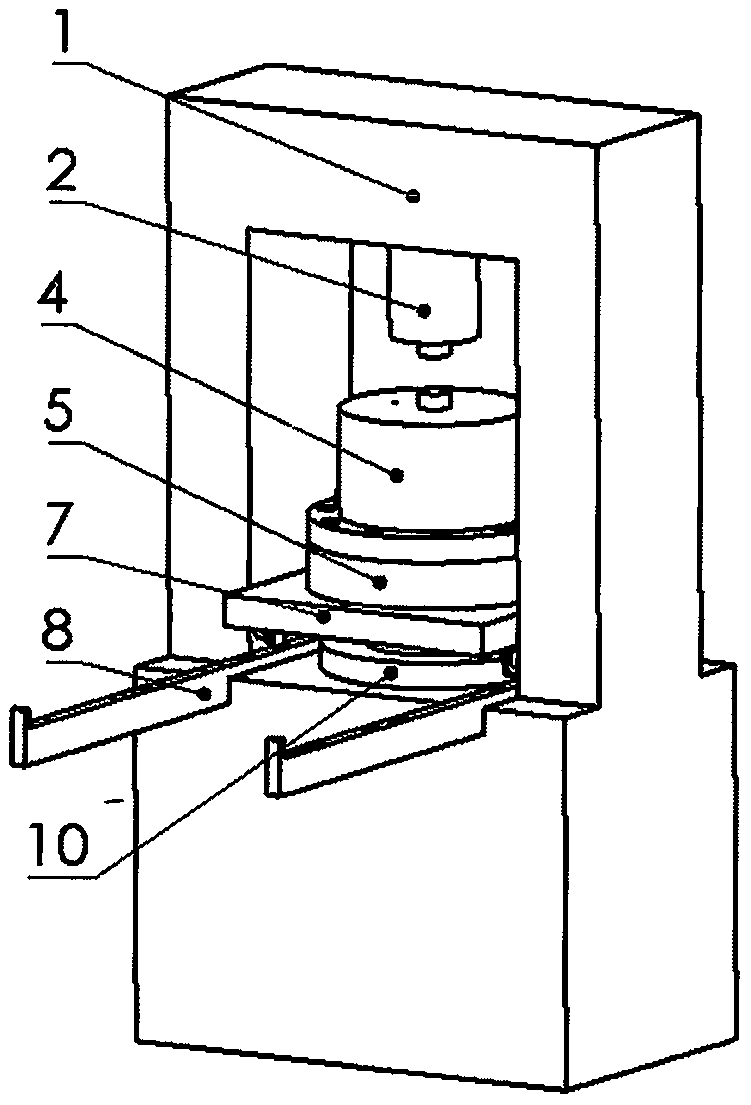

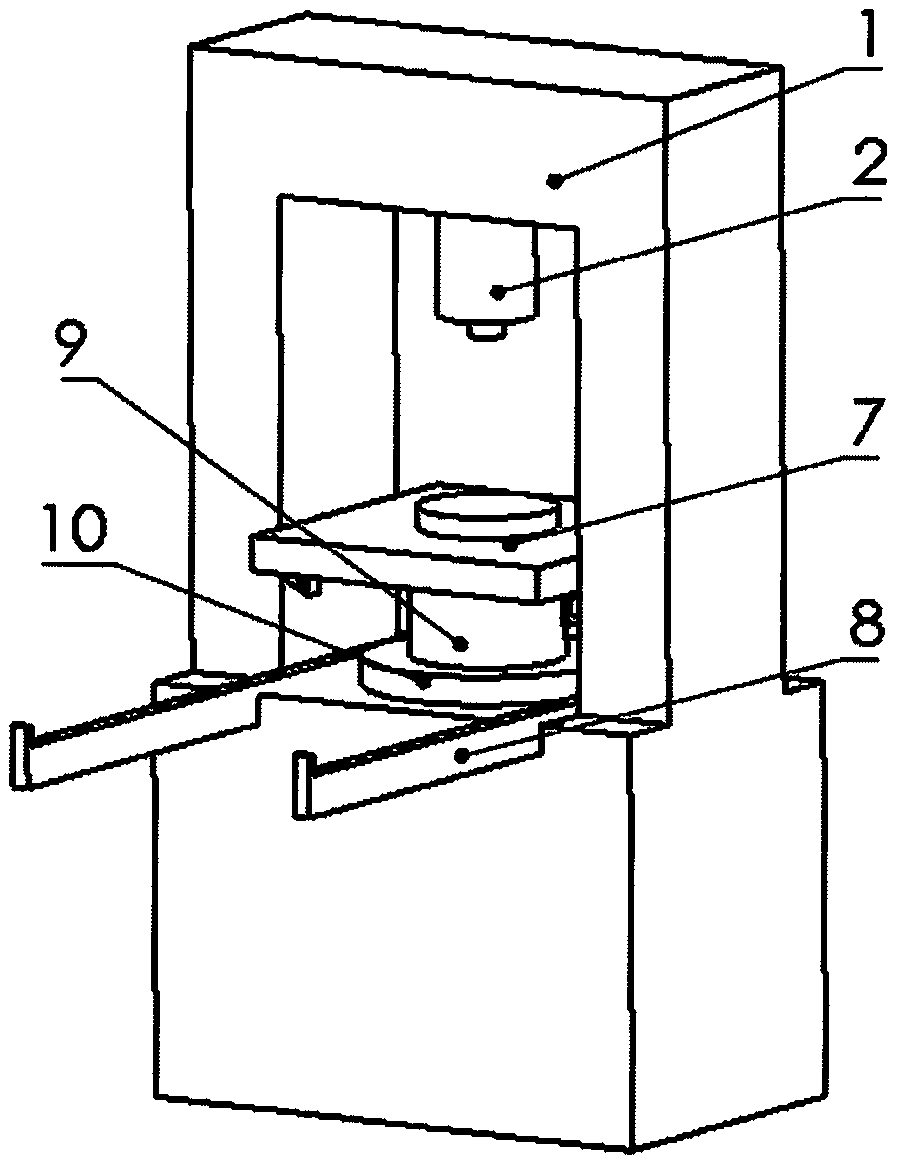

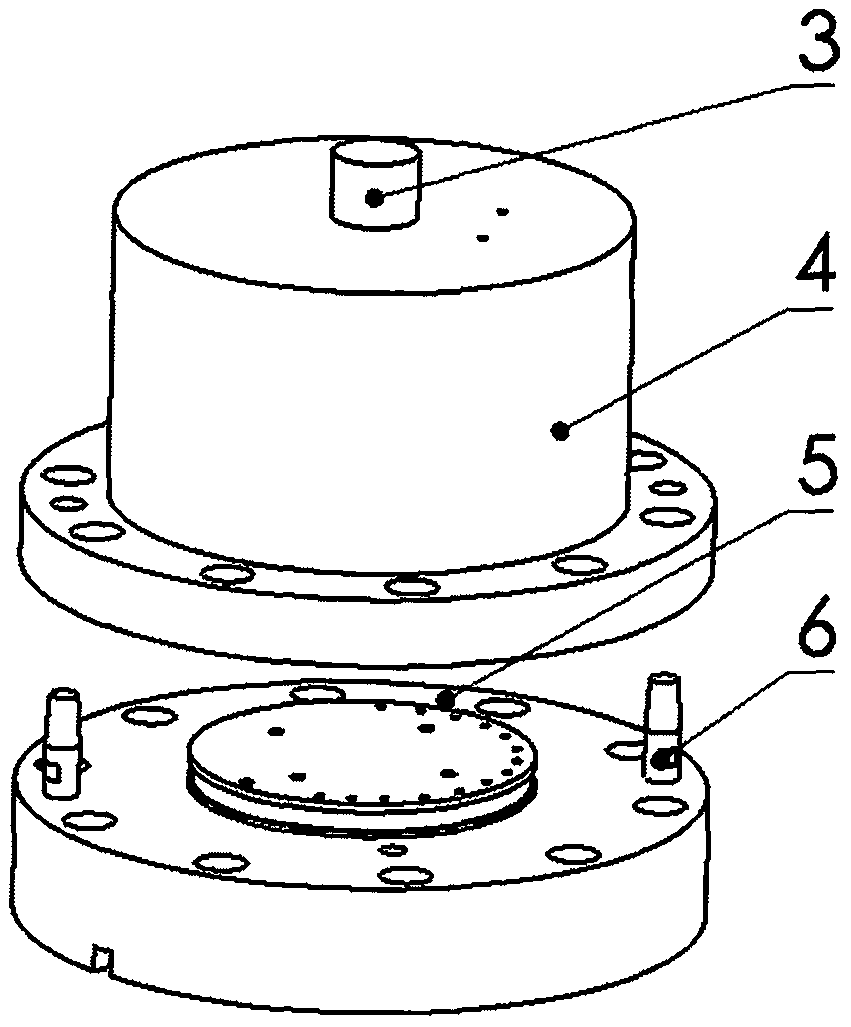

[0070] Figure 1-Figure 6 Shown is a preferred embodiment of an experimental device for testing rock fracture toughness under pore pressure conditions used in the experimental method described in Example 1, which includes a testing machine, a confining pressure chamber and a clamping fixture. The testing machine includes testing machine rigid frame 1, rigid frame pressure head 2, trolley 7, slide rail 8, hydraulic shaft 9, hydraulic cylinder 10, rigid frame pressure head 2 is installed on the upper end of testing machine rigid frame 1, and rigid frame pressure head 2 is installed on the lower end of testing machine rigid frame 1. Hydraulic cylinder 10, there is a hydraulic shaft 9 inside the hydraulic cylinder 10, the trolley 7 is located on the platform of the rigid frame 1 of the testing machine, the trolley 7 is installed on the hydraulic cylinder 10, when the hydraulic cylinder 10 drops to the lowest position, the trolley 7 can move along the slide rail 8 sliding; the conf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com