System and method for pre-warning copper electrolytic tank pole plate short circuit

An early warning system, copper electrolysis technology, applied in the field of copper electrolysis, can solve problems such as early warning of plates that cannot be short-circuited, achieve low cost, stable data information transmission, and avoid permanent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

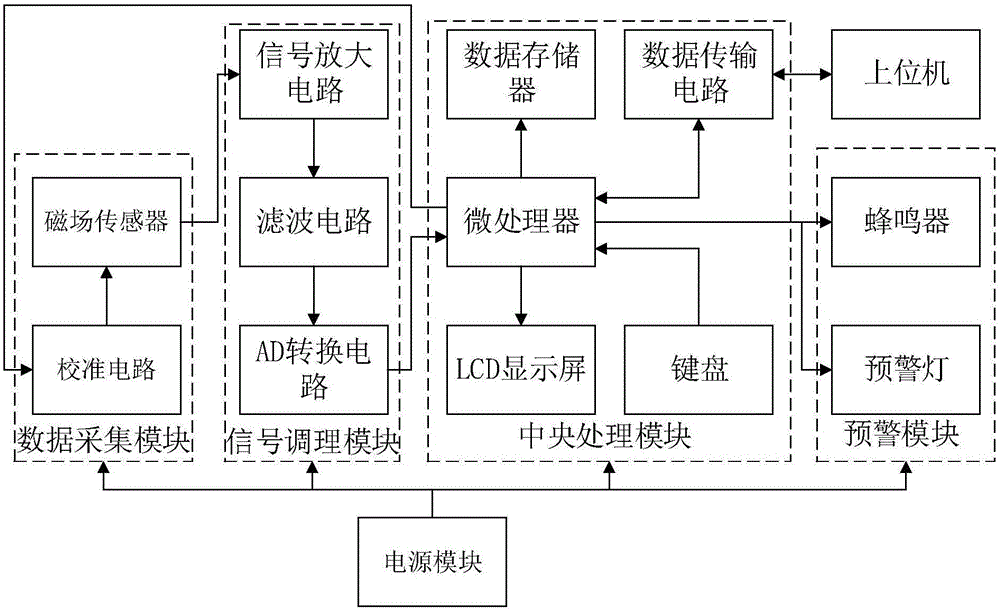

[0040] Embodiment 1. A short-circuit early warning system for copper electrolyzer plates, which will be combined below figure 2 A copper electrolytic cell plate short-circuit early warning system of the present invention is introduced in detail.

[0041] Such as figure 2 As shown, a copper electrolytic cell plate short-circuit early warning system includes a data acquisition module, a signal conditioning module, a central processing module, an early warning module and a power supply module.

[0042] The data acquisition module is used to collect the magnetic field strength signal around the pole plate of the copper electrolytic cell in real time; the signal conditioning module is used to process the data signal of the magnetic field strength signal; the central processing module is used to process the data signal When the last magnetic field strength signal reaches a preset condition, the early warning module is triggered to send out early warning information; the power sup...

Embodiment 2

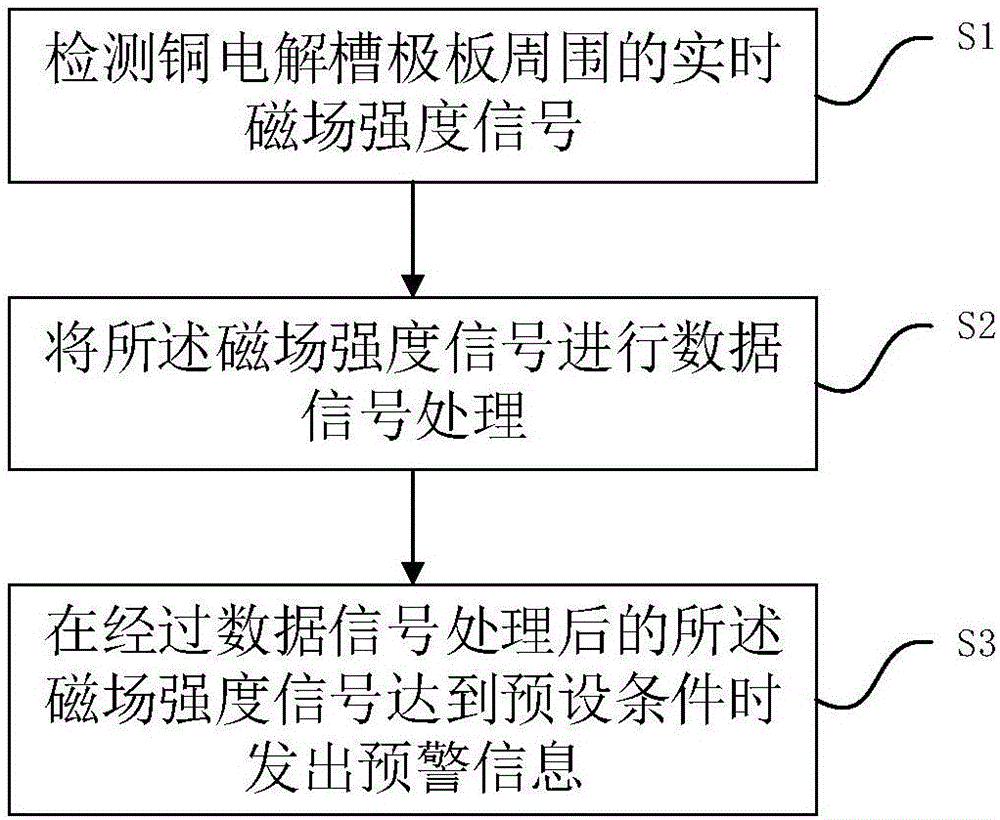

[0058] Embodiment two, a kind of copper electrolyzer pole plate short-circuit early warning method, will combine below image 3 A method for early warning of short circuit of copper electrolytic cell plate of the present invention is introduced in detail.

[0059] Such as image 3 Shown, a kind of copper electrolyzer pole plate short-circuit early warning method comprises the steps:

[0060] Step 1: Detect the real-time magnetic field strength signal around the plate of the copper electrolytic cell;

[0061] Step 2: performing data signal processing on the magnetic field strength signal;

[0062] Step 3: Send out warning information when the magnetic field strength signal after data signal processing reaches a preset condition.

[0063] The copper electrolytic cell plate short-circuit early warning method of the above-mentioned embodiment monitors the magnetic field strength around the copper electrolytic cell plate, thereby realizing the monitoring of the current change of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com