Method for generating exploded view of assembling process

A technology of assembly process and explosion diagram, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as error-prone, difficult to judge the distance of parts, and difficult to adjust the moving direction of parts to be consistent, etc., to achieve The effect of simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

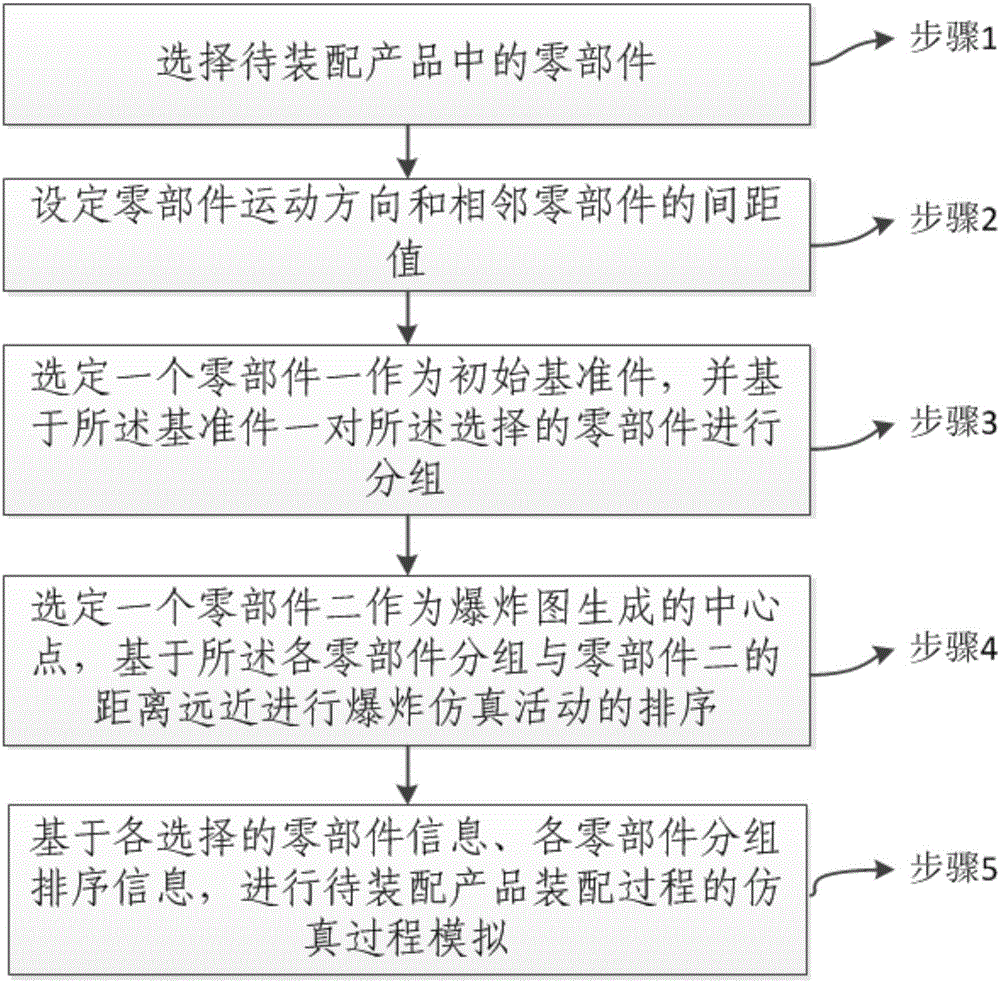

[0014] figure 1 In , a schematic flow chart of a method for generating an exploded view of an assembly process according to an embodiment of the present invention is given. Generally speaking, the method includes: step 1, select the components in the product to be assembled; step 2, set the movement direction of the components and the distance between adjacent components; step 3, select a component as the initial reference Parts, and group the selected parts based on the reference part; step 4, select a part two as the center point of the explosion diagram generation, based on the distance between the parts grouping and part two Sequencing of explosion simulation activit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com