First linear elastic estimation method for analyzing ultimate bearing capacity of planar circular tube structure

A technology for ultimate bearing capacity and structural analysis, applied in computing, special data processing applications, instruments, etc., it can solve the problems of complex computing process, low computing efficiency, difficult engineering application, etc., and achieve the effect of high computing accuracy, overall safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0041] This embodiment is a specific example of a linear elastic estimation method for the analysis of the ultimate bearing capacity of a planar circular tube structure, including the following steps:

[0042] (1) Establish the structural analysis model of the plane circular tube:

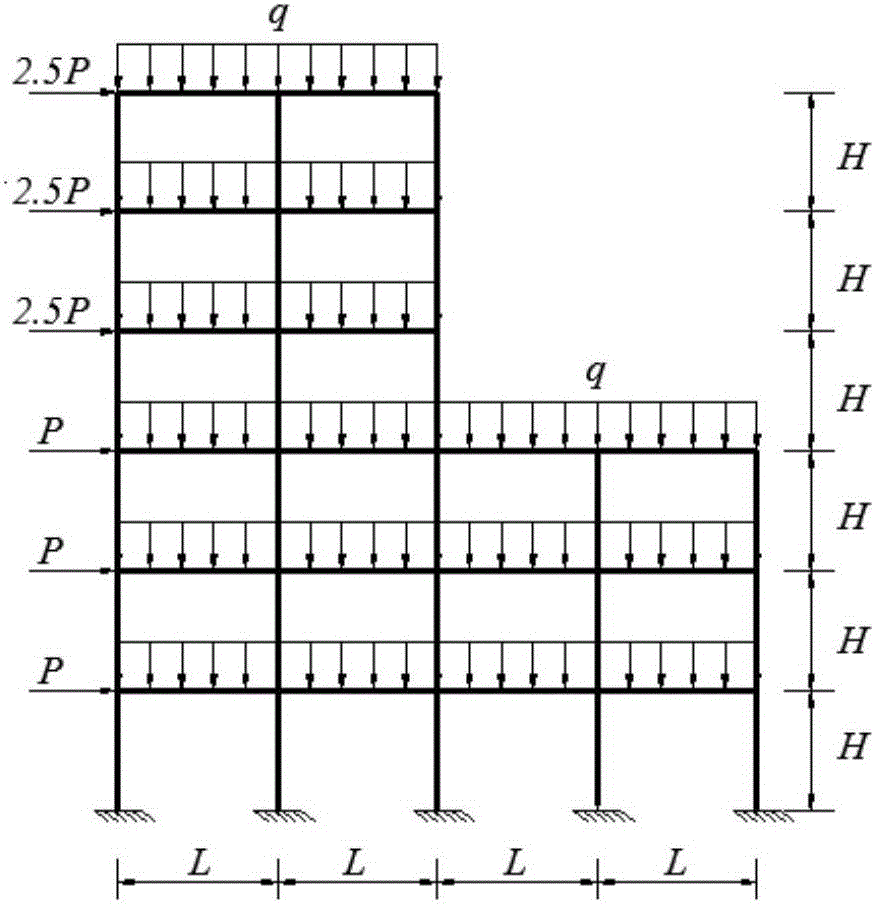

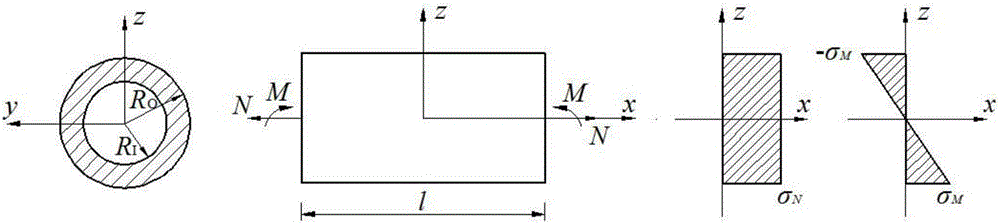

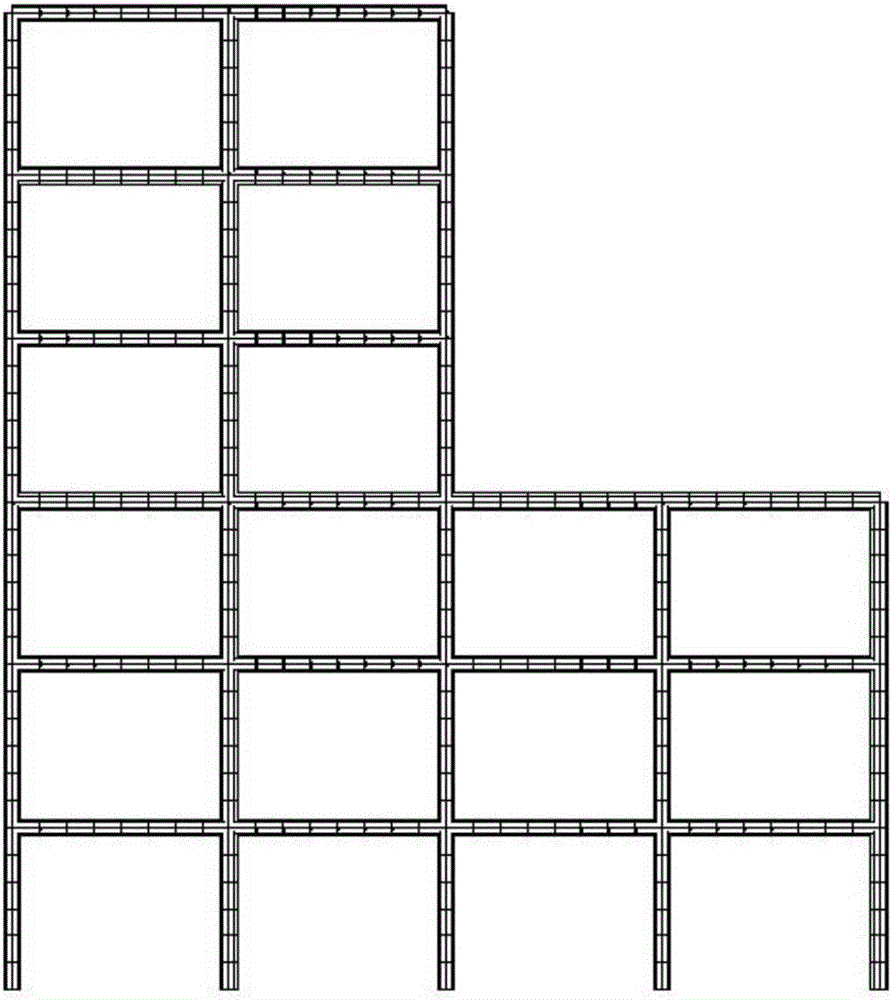

[0043] The beam length L of a plane circular tube structure is 4m, and the column height H is 3m. The geometric dimensions and material parameters of other plane circular tube structures are shown in Table 1. Under the action of vertical uniform load q and horizontal concentrated load P, P=qL / 4, the calculation model of the plane circular tube structure is as follows figure 1 As shown, its cross-section and stress distribution are shown as figure 2 shown. Using ANSYS software for modeling and beam element simulation, the finite element mesh of the planar circular tube structure is as follows image 3 .

[0044] Table 1 Structural dimensions and material parameters of planar circular tubes

[...

Embodiment 2

[0059]For the analysis of the ultimate bearing capacity of the planar circular pipe structure described in Example 1, EPIA, whose calculation accuracy has been recognized in the field, was used to solve the problem, and ANSYS software was used to extract the number of iterations required by EPIA to solve the ultimate bearing capacity. The calculation results are shown in Table 4 .

[0060] Table 4 Comparison of calculation accuracy and efficiency between EPIA and linear elastic estimation method

[0061] calculation method EPIA Linear Elastic Estimation Method ultimate bearing capacity 2.965kN·m -1

[0062] It can be seen from Table 4 that the calculation accuracy of the ultimate bearing capacity of the plane circular pipe structure obtained by the linear elastic estimation method is only 1.45% compared with EPIA. EPIA needs 84 iteration steps to solve the ultimate bearing capacity of the planar circular tube structure, and the calculation efficiency is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com