Trial stand for welder training

A test frame and welder technology, applied in the field of welder training, can solve the problems of not being able to satisfy the pipe sample, complicated operation, and single function at the same time, and achieve the effects of saving training auxiliary time, simple operation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

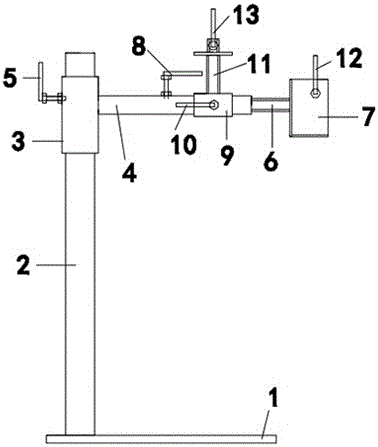

[0012] Such as figure 1 A test stand for welder training is shown, including a fixed arm, a rotating arm, a plate clamp device, and a pipe clamp device.

[0013] The fixed arm includes a base 1 and a first fixed tube 2;

[0014] The rotating arm includes a first limiting tube 3 , a first fastening screw 5 , a second fixing tube 4 , and a second fastening screw 8 .

[0015] The plate clamping device includes a second limit tube 6 , a plate clamp fixture 7 , and a fourth fastening screw 12 .

[0016] The pipe clamp device includes a third limit tube 9 , a third fastening screw 10 , a pipe clamp 11 , and a fifth fastening screw 13 .

[0017] The first fixed pipe 2 is vertically fixed above the base 1 and the length of the first fixed pipe 2 is 1.5m-2.0m. The first limiting tube 3 runs through the first fixing tube 2 , and the first limiting tube 3 is movably connected to the first fixing tube 2 through the first fastening screw 5 . One end of the second fixed tube 4 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com