Support mould upright post for cast wall bodies

A technology for supporting formwork columns and walls, which is applied to the connection parts of formwork/formwork/work frame, the on-site preparation of building components, and construction, etc., can solve the problems of high cost, troublesome operation, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

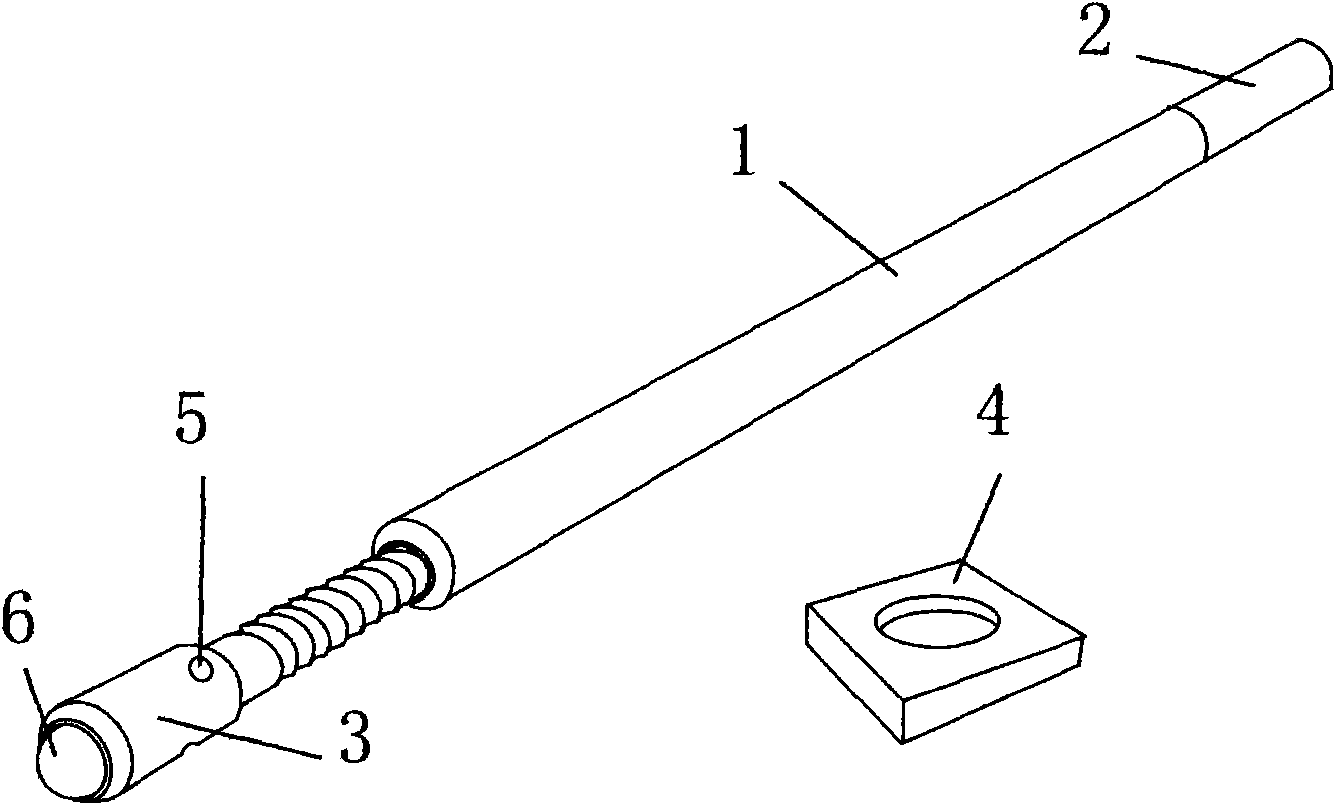

[0022] Formwork columns are used for pouring walls in this example, such as Figure 1 As shown, it is a formwork column with a jack device, which is composed of an upper strut 1 and a bottom jack. The bottom end of the strut 1 is connected with the upper end of the jack. 2 and support rod 1 socket or screw fit. The jack is a screw jack, which consists of a telescopic adjustment rod 3, a base 4 with a circular groove and a rotating device 5, wherein the bottom end of the strut 1 and the upper end of the telescopic adjustment rod 3 are threaded, and the bottom end of the telescopic adjustment rod 3 A movable ball 6 matched with the circular groove on the base 4 is provided, and the rotating device 5 is a hole arranged on the telescopic adjusting rod 3, and the telescopic adjusting rod 3 is rotated by an iron rod inserted into the hole.

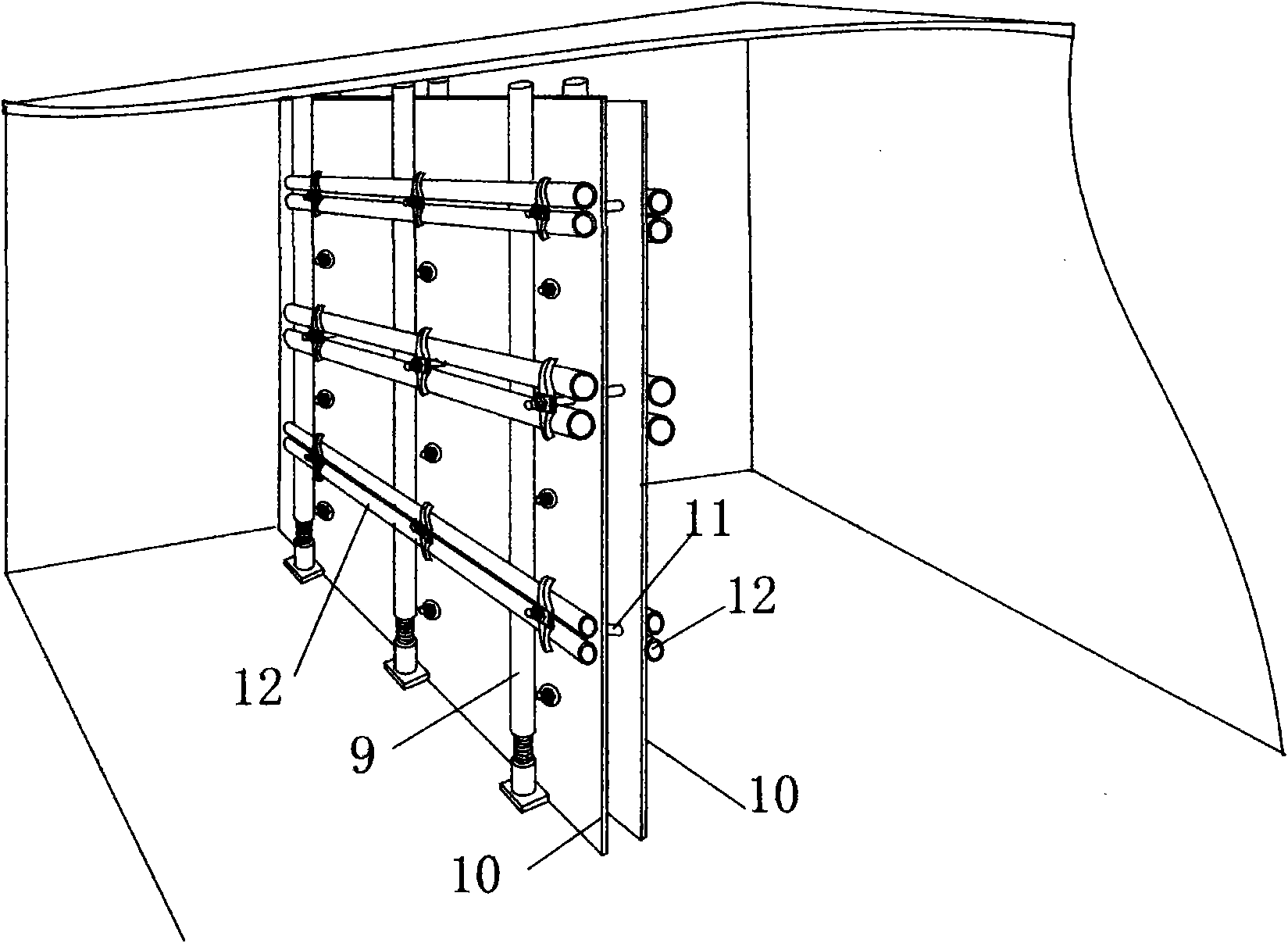

[0023] When used, such as Figure three As shown, the base 4 is placed at a certain distance on the positioning line of the wall to be poured...

Embodiment 2

[0025] Formwork columns are used for pouring walls in this example, such as Figure 1 Shown, except screw jack, all the other are the same as embodiment one.

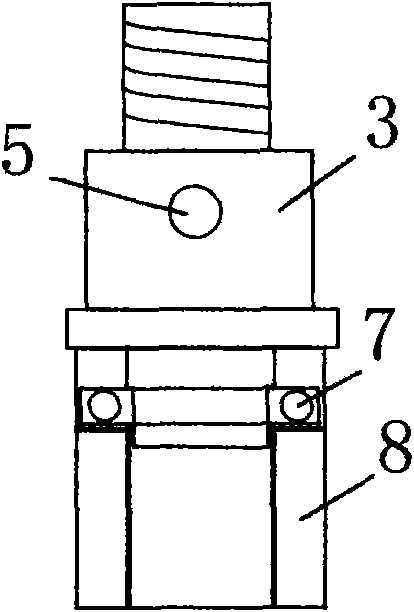

[0026] The screw jack used in this example is composed of a telescopic adjusting rod 3, a bearing 7, a bearing seat 8 and a rotating device 5, wherein the bottom end of the strut 1 and the upper end of the telescopic adjusting rod 3 are threaded, and the bottom of the telescopic adjusting rod 3 The end is connected with the bearing seat 8 through the bearing 7, and the rotating device 5 is a hole arranged on the telescopic adjustment rod 3, and the telescopic adjustment rod 3 is rotated by the iron rod inserted in the hole.

Embodiment 3

[0028] The pouring wall of this example uses formwork uprights, and except jack, all the other are with embodiment one. The jack used in this example is an existing hydraulic jack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com