Folding ironing device used for woven label production and convenient to use

A convenient and controllable technology, applied in the fields of weaving labels and clothing, can solve the problems of unsatisfactory manual folding effect, poor fabric adaptability, complicated mechanical structure, etc., achieving the effect of simple structure, convenient equipment use, and guaranteed half-folding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

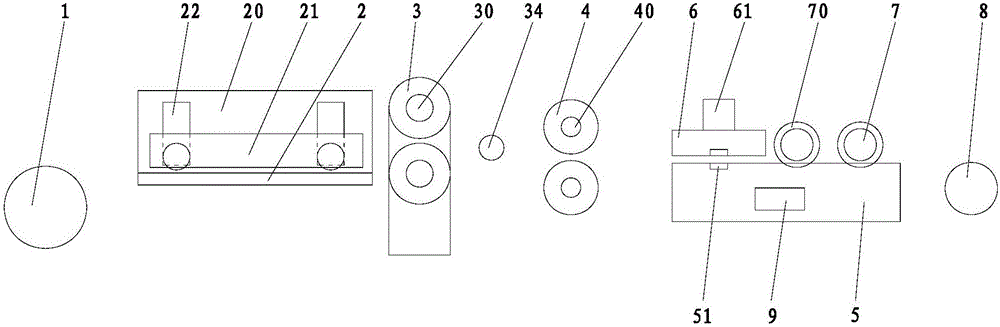

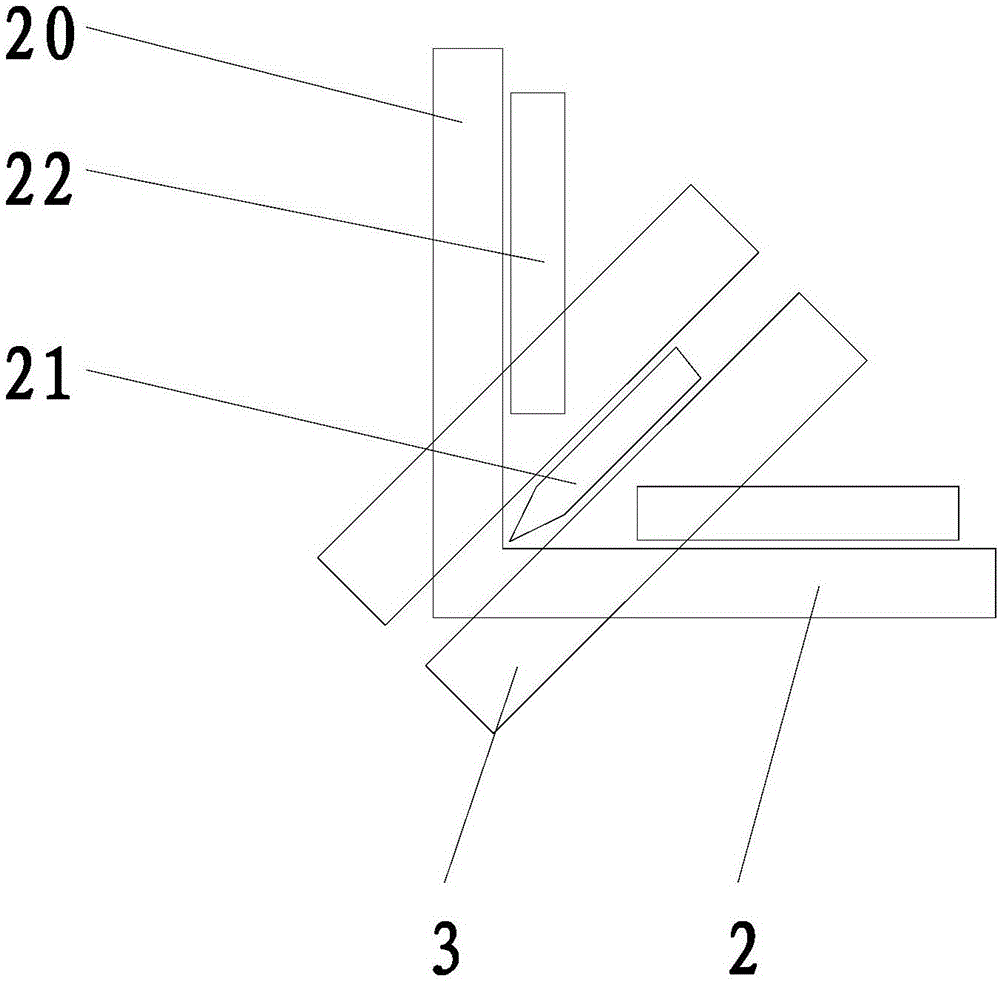

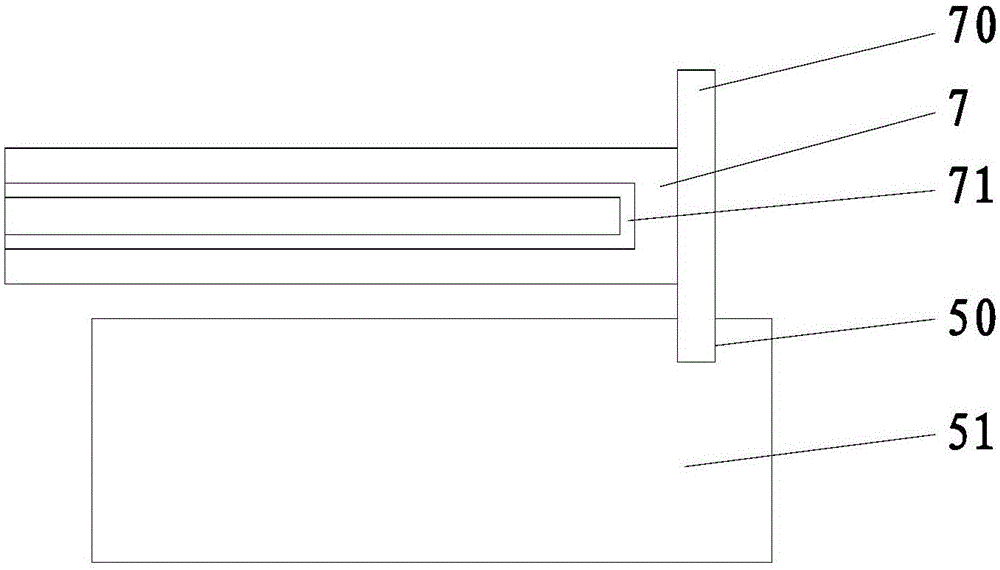

[0021] refer to figure 1 , figure 2 and image 3 , a convenient folding and ironing device for woven label production according to the present invention, comprising a ironing module (6), a lower pressing rod (61), a pressing shaft (7), a cutting blade (70), and a control device (9) And the coil feeding mechanism (1), the transition table (2), the folding roller group, the transport roller group, the ironing table (5), and the pulling device (8) arranged in sequence, and the transition table (2) is provided on one side There is a side baffle (20), a crease pressing plate (21) is arranged on the angle bisector of the transition table (2) and the side baffle (20), and the surface of the transition table (2) and the side baffle (20) is provided with A plurality of auxiliary rollers (22), the double-folding roller group is composed of two first rollers (3), the gap between the two first rollers (3) is located on the same plane as the crease pressing plate (21), The transport ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com