A spring operating mechanism for high voltage circuit breaker

A high-voltage circuit breaker and operating mechanism technology is applied in the field of spring operating mechanisms to achieve the effects of ingenious structural design, perfect coordination and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

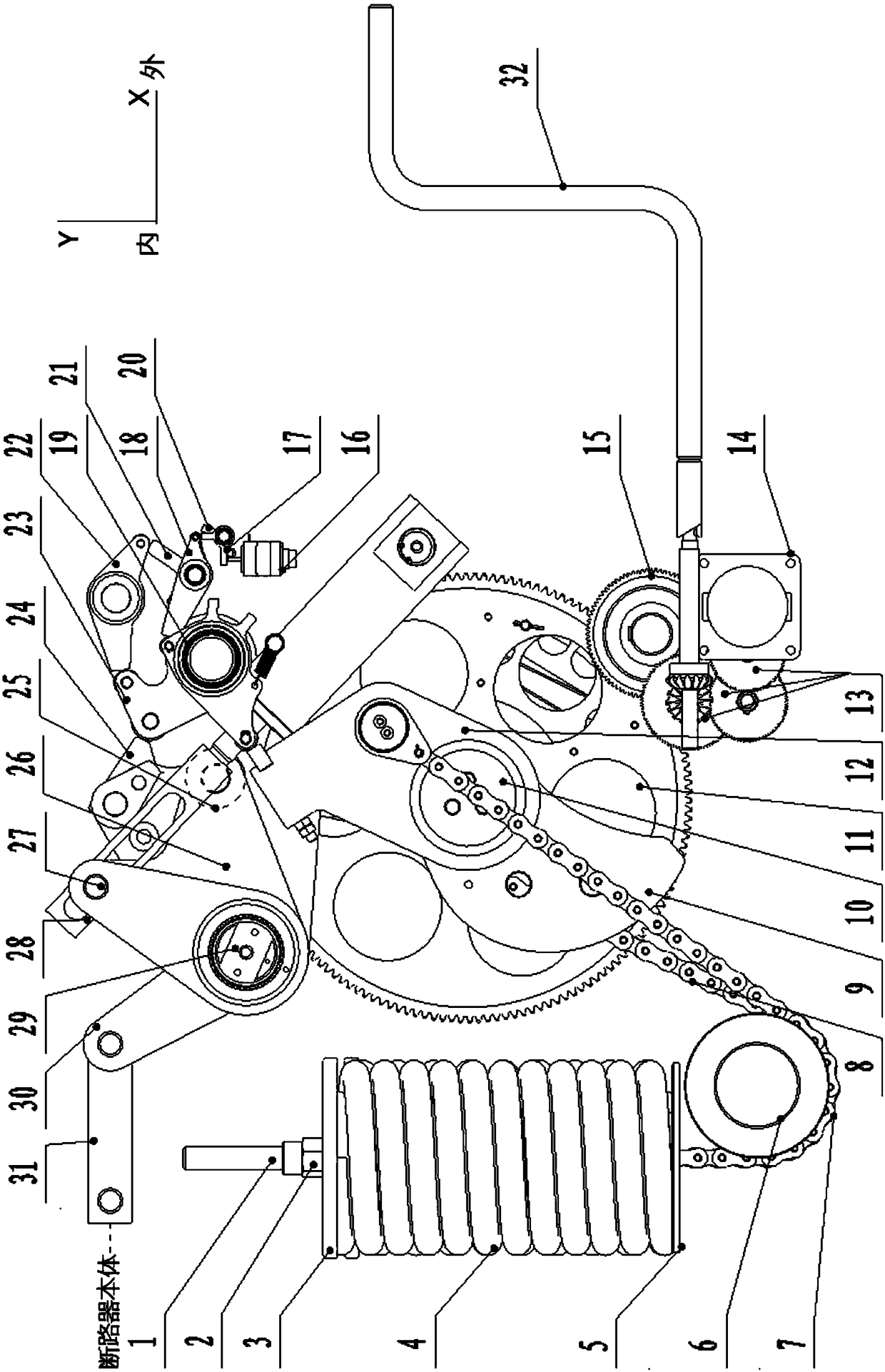

[0033] see figure 1 , figure 2 , image 3 Shown is a spring operating mechanism and buffer module solution for a high-voltage circuit breaker.

[0034] see figure 1 , assuming that the spring operating mechanism of the high-voltage circuit breaker is used to connect with the circuit breaker, the outward direction is the X direction, and the direction perpendicular to the X direction is the Y direction, and the XOY plane is located in the plane where the large gear 11 of the energy storage module is located .

[0035] The solution includes a base module, an opening and closing spring module, an energy storage module, an energy storage shaft module, an output shaft module, a buffer module, a closing and tripping module, and an opening and tripping module during specific implementation. see Figure 4 , After the three phases of the spring operating mechanism of the high voltage circuit breaker are arranged side by side, the right side is the observation, operation and maint...

Embodiment 2

[0052] see Figure 4 , a three-phase high-voltage circuit breaker, A, B, C three-phase circuit breaker bodies are arranged side by side in parallel, and the spring operating mechanism in the first embodiment of the three is respectively fixed on the A, B, C three-phase circuit breaker ends and are parallel to each other. Electromagnets, motors, buffers, etc. are located on the outside where it is easy to adjust, which is convenient for installation, maintenance and debugging; at this time, the buffer modules are all tilted upward to the left, which effectively reduces the risk of oil leakage from the buffer modules; When the three phases of high-voltage circuit breakers are arranged side by side and the space is limited, it is convenient for the installation, commissioning and maintenance of the spring operating mechanism.

Embodiment 3

[0054] A single-phase high-voltage circuit breaker, which adopts the above-mentioned spring operating mechanism, and is fixed below the body of the single-phase high-voltage circuit breaker. At this time, the electromagnet, motor, buffer, etc. are all located at the lower side for easy adjustment, which is convenient for installation, Maintenance and debugging; at this time, the buffer modules are tilted upward to the upper right, effectively reducing the risk of oil leakage from the buffer modules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com