Wind generating set closed cooling system

A technology for wind turbines and cooling systems, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as damage to mechanical seals, unit shutdown, inconsistent life of circulating pumps, etc., to prolong life. , The effect of increasing power generation and reducing inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

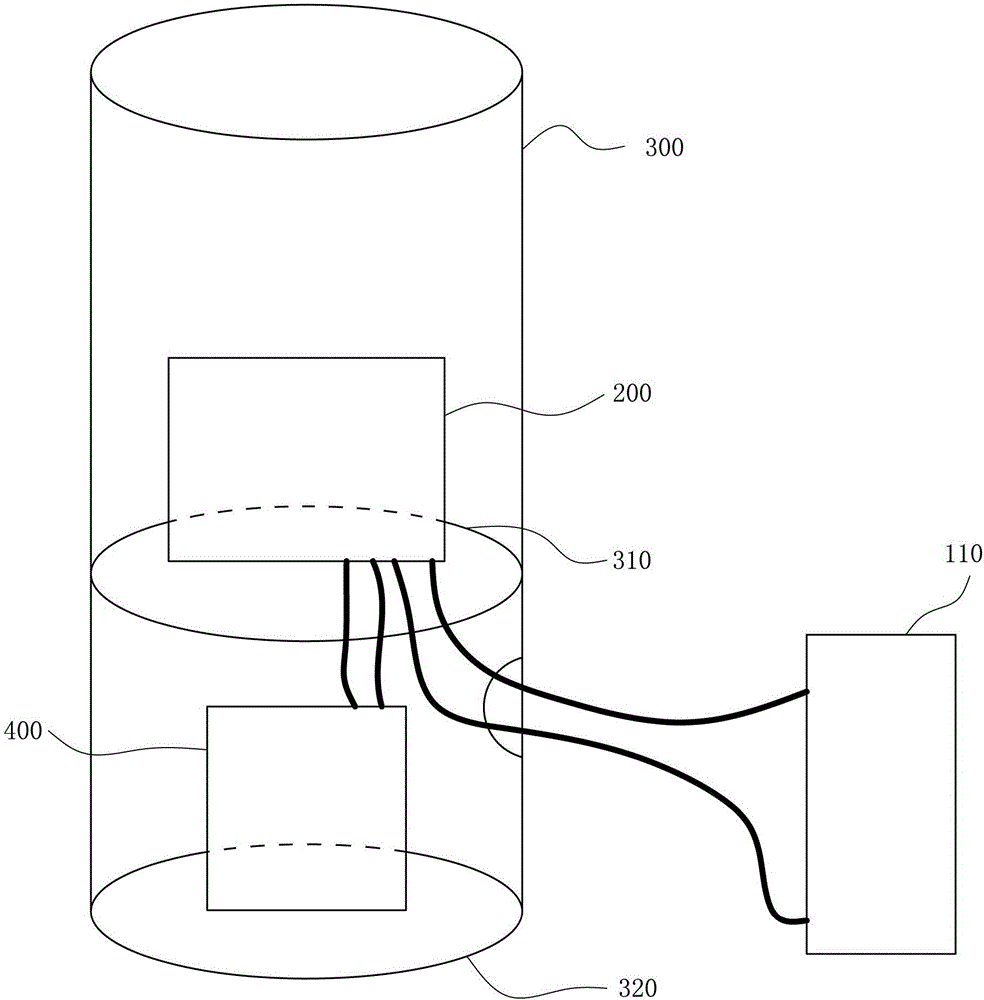

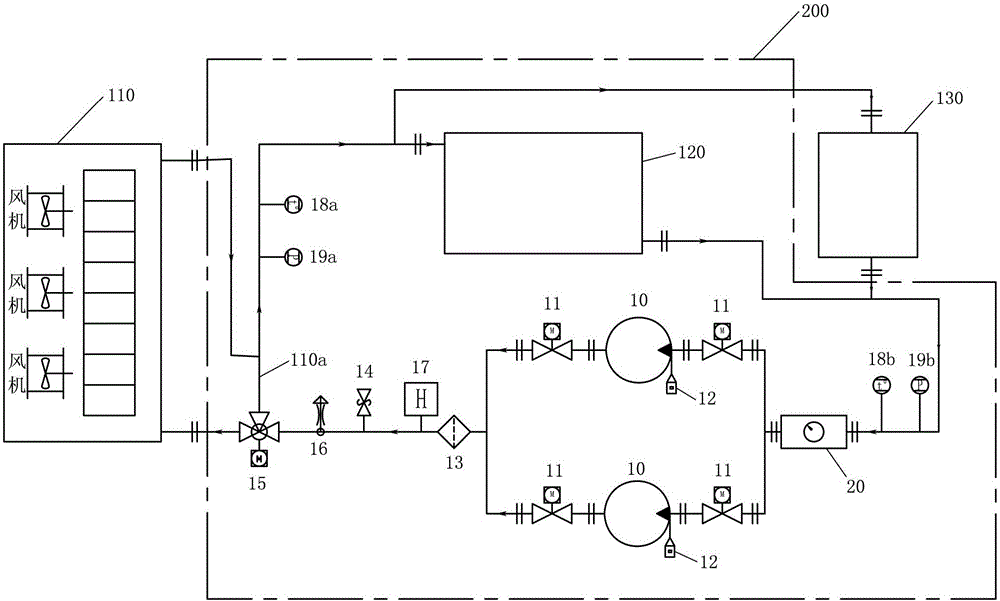

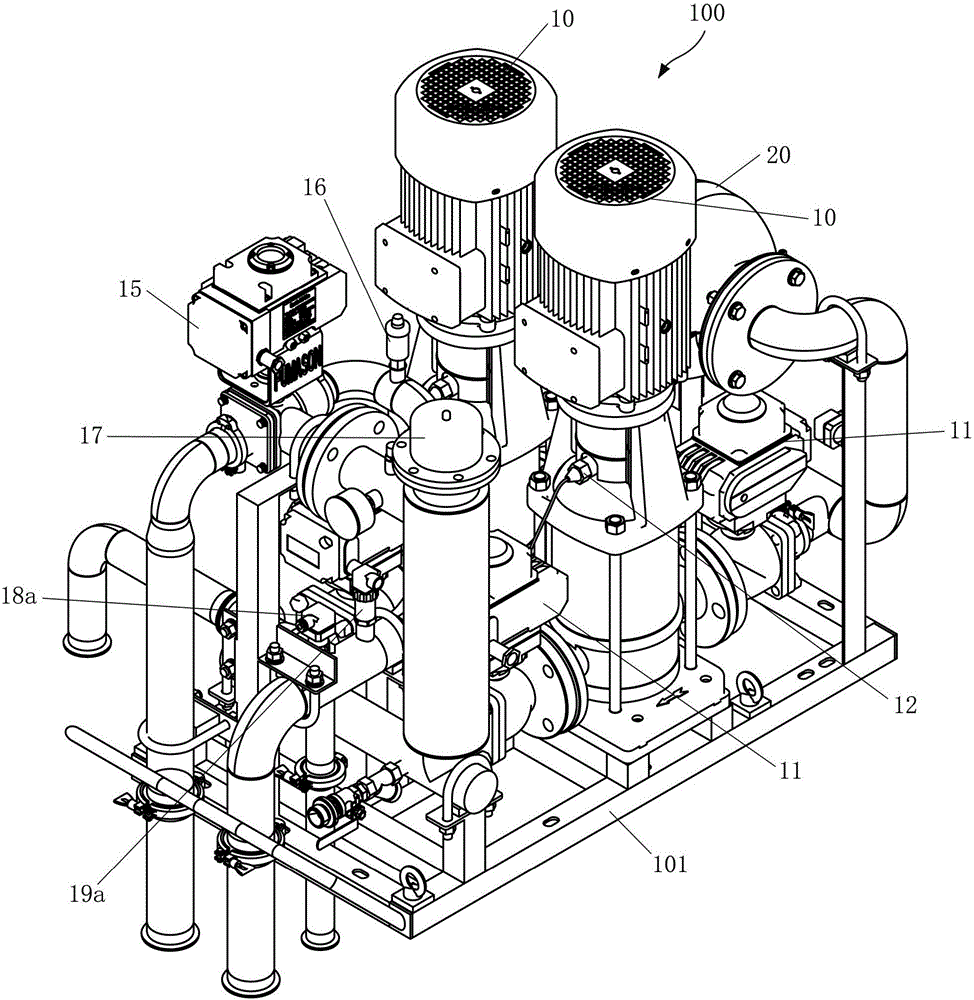

[0036] Such as figure 1As shown, the converter cabinet 200 and the main transformer cabinet 400 are placed on different layers inside the tower 300, for example, the main transformer cabinet 400 is arranged on the base platform 320 at the bottom of the tower 300, and the converter cabinet 200 is arranged on the tower The first layer platform 310 inside the cylinder. A main transformer is installed in the main transformer cabinet 400, and a main transformer heat exchange module for dissipating heat is provided inside the main transformer. A converter is installed in the converter cabinet 200, and a converter heat exchange module is provided inside the converter to dissipate heat. In the converter, heat is mainly generated in the IGBT power module. Therefore, the heat exchange module of the converter is mainly used to dissipate heat from the IGBT p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com