Lifter with electropermanent magnets

A technology of lifters and permanent magnets, which is applied in the direction of cranes, permanent magnets, load suspension components, etc., can solve problems such as dangerous temperature and shorten the operation time of lifters, and achieve the effect of ensuring operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

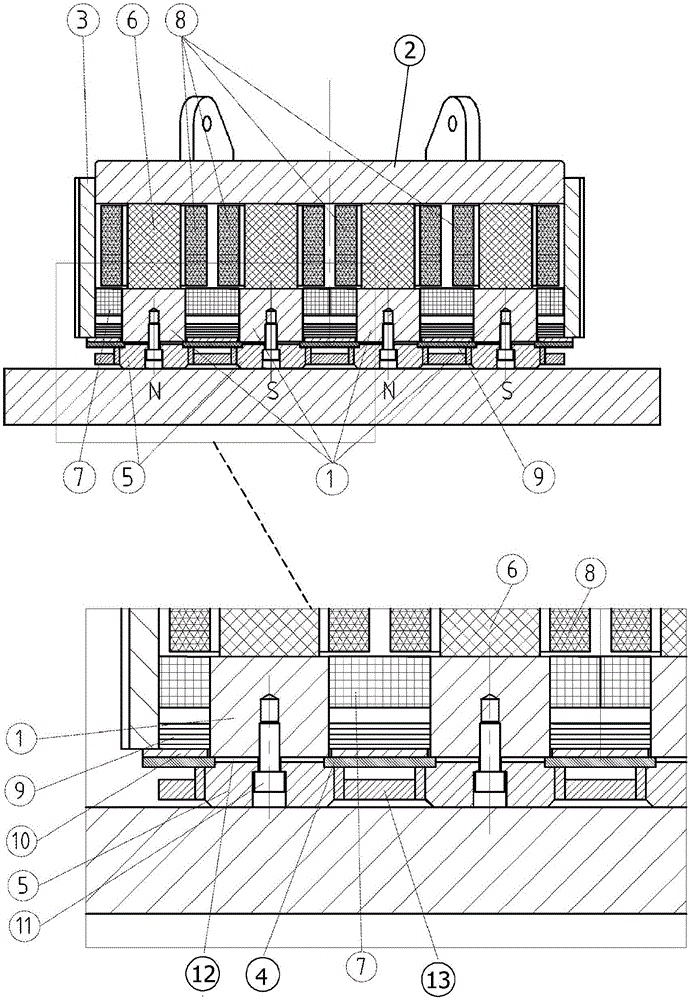

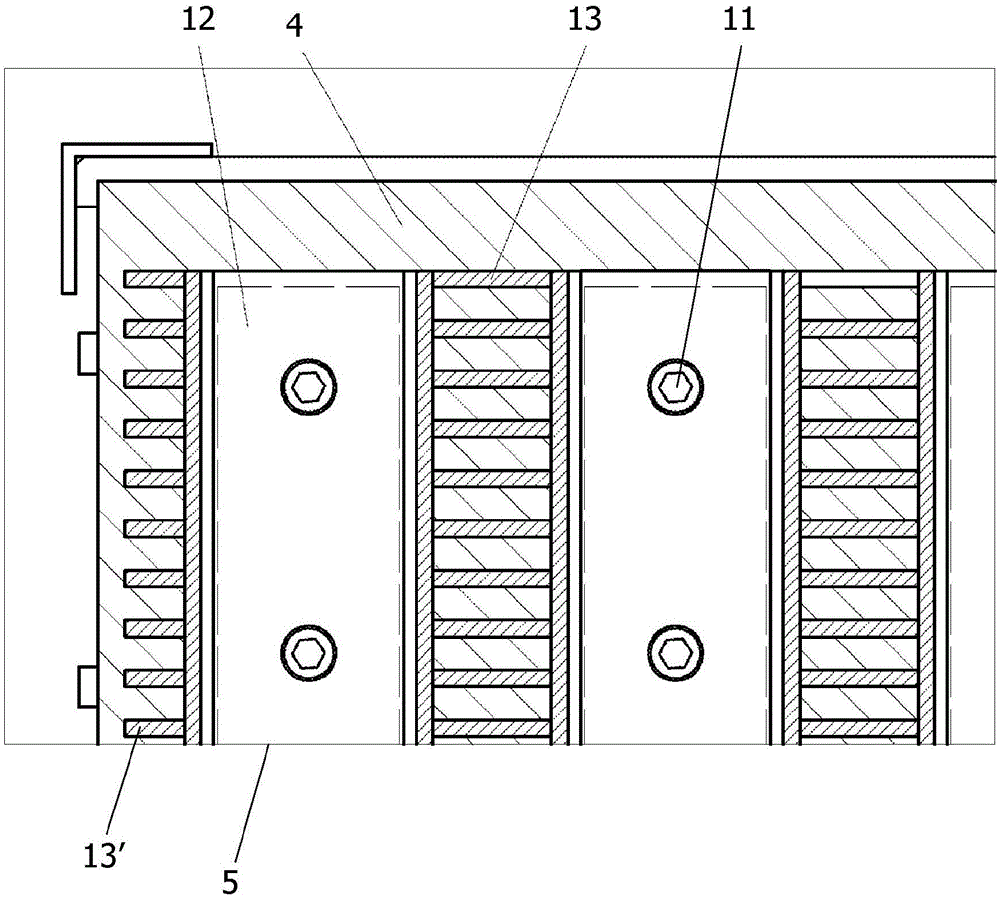

[0017] Referring to these figures, it can be seen that a jack with electro-permanent magnets according to the present invention generally includes an outer support structure, a plurality of electro-permanent magnets and a regulating circuit.

[0018] The support structure comprises a top cover 2 provided with a coupling for connection to a lifting device such as a crane, two peripheral walls 3, and a heat shield 9 provided to protect the magnets from radiation by the hot ferromagnetic material to be lifted. Thermal bottom closure plate 10 . Same as the circuit pole 1 and pole piece 5, said structure is obviously made of high magnetic permeability material (usually mild steel) to minimize the reluctance of the magnetic circuit, the pole piece 5 for contacting the load to be lifted is in A closure plate 10 protrudes below and is fixed to pole 1 by screws 11 .

[0019] Each electro-permanent magnet comprises a reversible magnet 6 arranged on top of a pole 1 in contact with it an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com