Bypass valve arrangement and exhaust system

A technology of exhaust system and bypass valve, which is applied in the direction of valve device, exhaust treatment, noise reduction device, etc., and can solve the problem of a large amount of space in the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

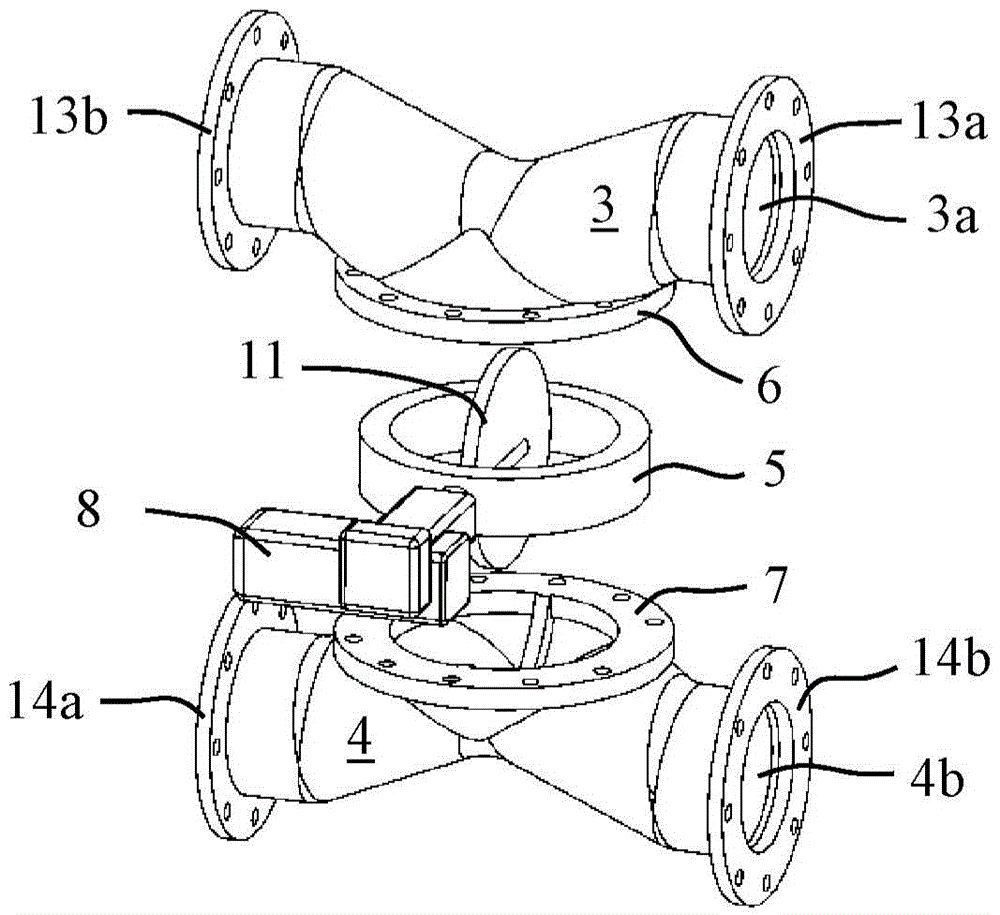

[0018] Embodiments of the present invention will now be described in more detail with reference to the accompanying drawings.

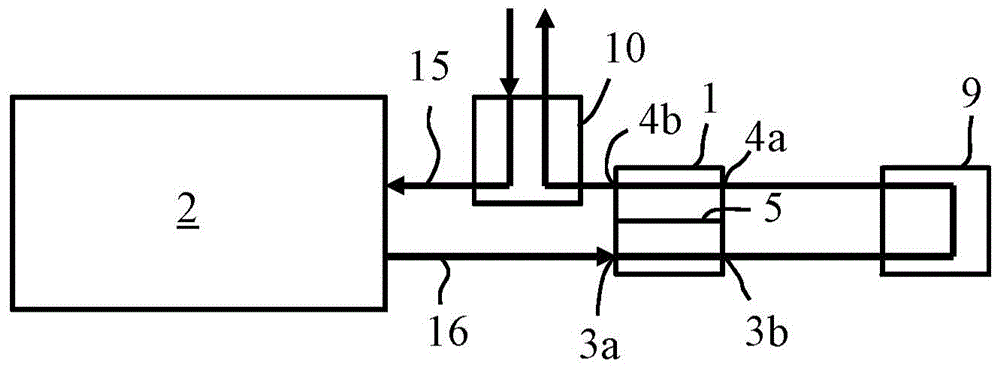

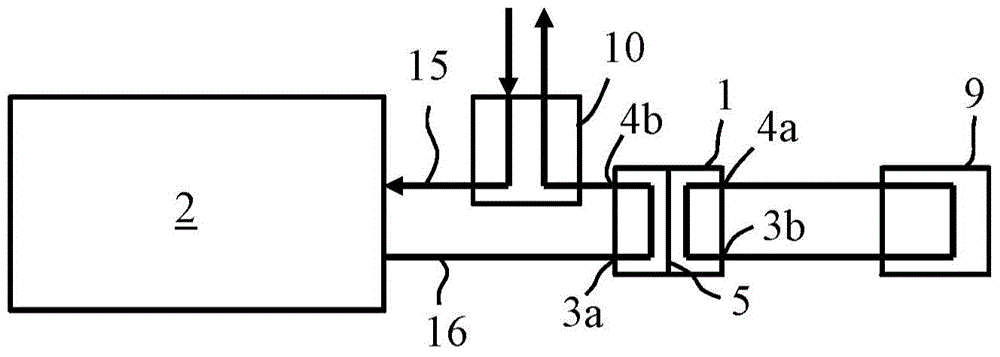

[0019] figure 1 Internal combustion engine 2 is shown schematically. The engine 2 is a large internal combustion engine 2, such as an engine used as a main or auxiliary engine of a ship or for producing electricity in a power plant. The exhaust system of the engine 2 comprises an exhaust manifold 16 and a turbocharger 10 for supercharging the intake air of the engine 2 and directing this air into the cylinders of the engine 2 through an intake manifold 15 . The exhaust system is also provided with a catalyst device 9 which may, for example, be an oxidation catalyst reducing the hydrocarbon and CO emissions of the engine 2 . Oxidation catalysts require relatively high exhaust gas temperatures, and the oxidation catalyst 9 of the engine 2 is therefore located upstream of the turbocharger 10 in the exhaust system. Under some operating conditions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com