Closing device having a control disk and method for closing a hood by means of such a closing device

A technology of locking device and control panel, which is applied in the fields of fastening carpets, electric locks, building locks, etc. It can solve the problems of complex electronic systems, high locking noise, high opening force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

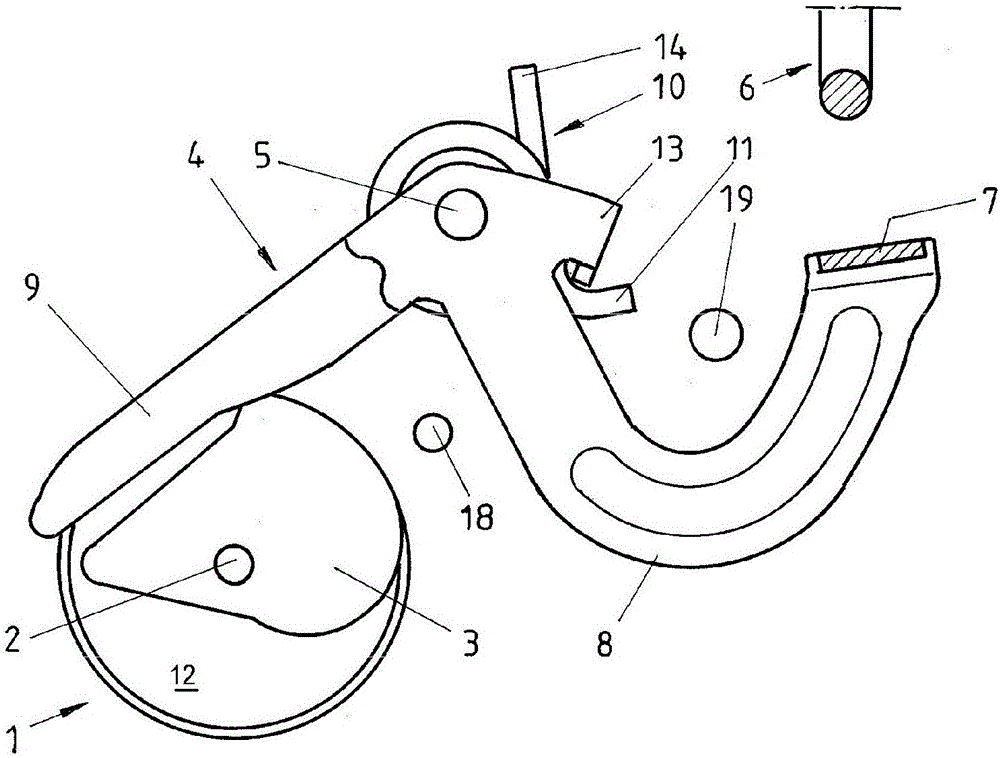

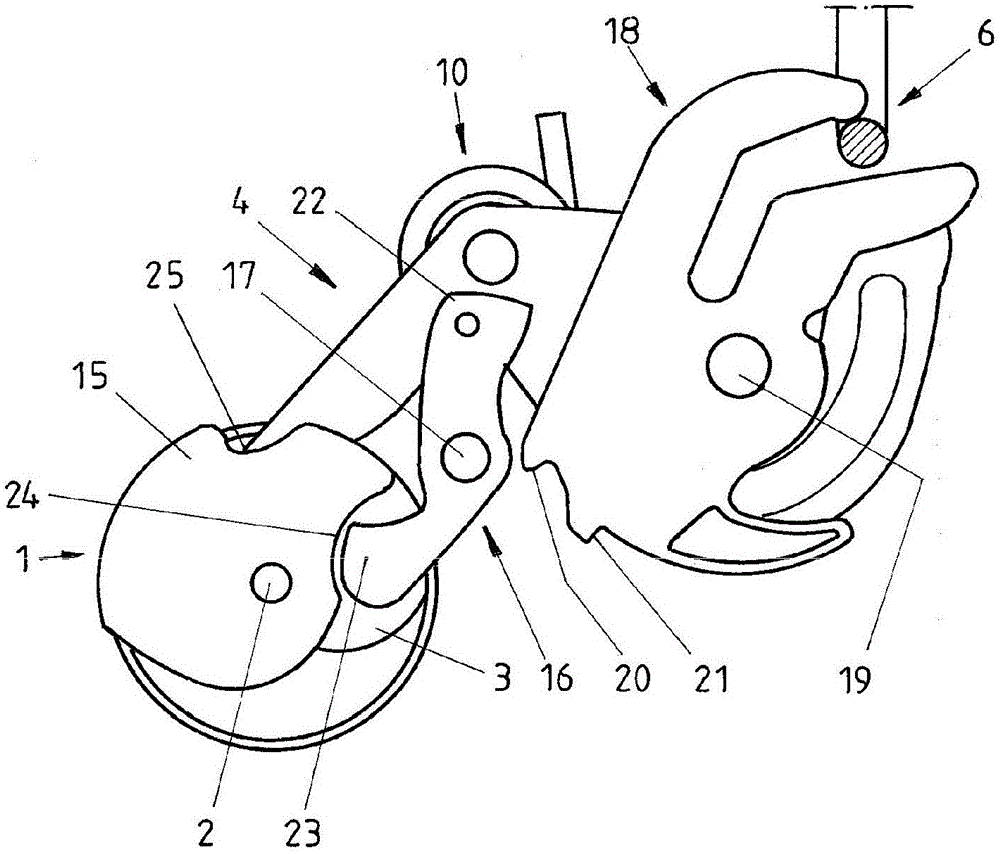

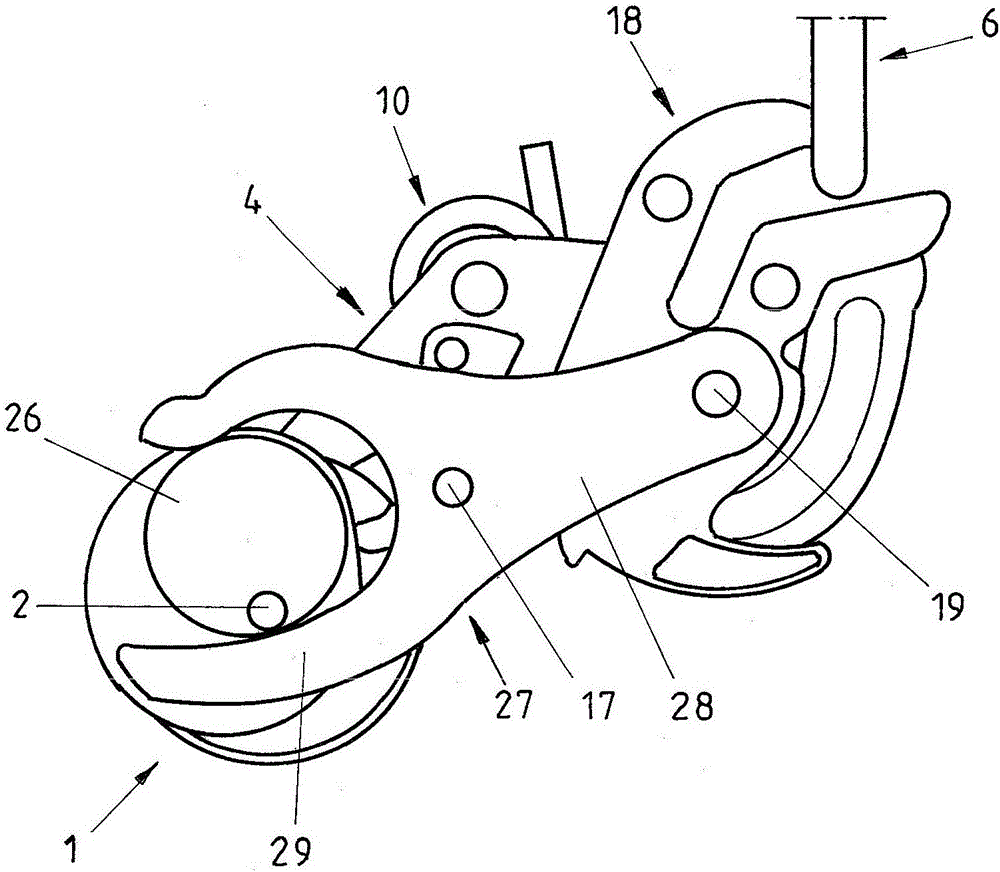

[0022] exist figure 1 shows the first level of the control panel 1 together with the associated movable components. The control disc 1 is rotatable about its axis 2 . The approximately triangular control contour 3 for pivoting the ejector lever 4 is located above the gear wheel 12 in the first layer. The control contour 3 likewise extends in an arc in the region adjoining the edge region of the gear wheel 12 in order to be able to hold the ejector lever 4 in the lowered position and the control disk 1 to still be able to rotate for a controlled movement of the other components. The ejector rod 4 can swing around the axis 5 . When the corresponding cover is closed, the catch or stop 6 of the cover finally abuts against the free end 7 of the lever arm 8 of the ejector lever 4 . If the catch 6 rests against the free end 7, the cover can be lifted or lowered by swiveling the ejector rod 5 in the following way: If the control disc 1 is turned counterclockwise, the control profil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com